Real-Time Visibility for Managing Remote Warehouses

In warehouse management, real-time visibility has become a game-changer for managing operations across various industries. Real-time tracking and data integration can significantly improve efficiency, reduce errors, and enhance decision-making processes. For businesses managing remote warehouses, real-time visibility is not just a luxury; it’s an essential tool for ensuring smooth operations and maintaining customer satisfaction.

In this article, we’ll explore why real-time visibility is crucial for managing remote warehouses, its key benefits, and how it helps streamline logistics, inventory control, and operational efficiency. Let’s dive into how adopting this technology can boost your supply chain management, even if your warehouse is far from your primary location.

What is Real-Time Visibility in Warehouse Management?

Real-time visibility refers to the ability to access up-to-date information on the status of goods, inventory, shipments, and operations within the warehouse. With real-time visibility tools, managers can track the movement of goods, monitor stock levels, and receive instant notifications of any discrepancies or issues that arise, all in real-time.

For remote warehouses, where physical presence and manual checks are often limited, real-time visibility is even more crucial. It enables warehouse managers to monitor, control, and optimize operations from anywhere, at any time, using cloud-based software or integrated systems.

Key Benefits of Real-Time Visibility for Remote Warehouses

1. Improved Inventory Management

One of the most significant challenges in managing remote warehouses is keeping track of inventory. With real-time visibility, businesses can instantly view their stock levels, reducing the chances of stockouts, overstocking, or errors in order fulfillment.

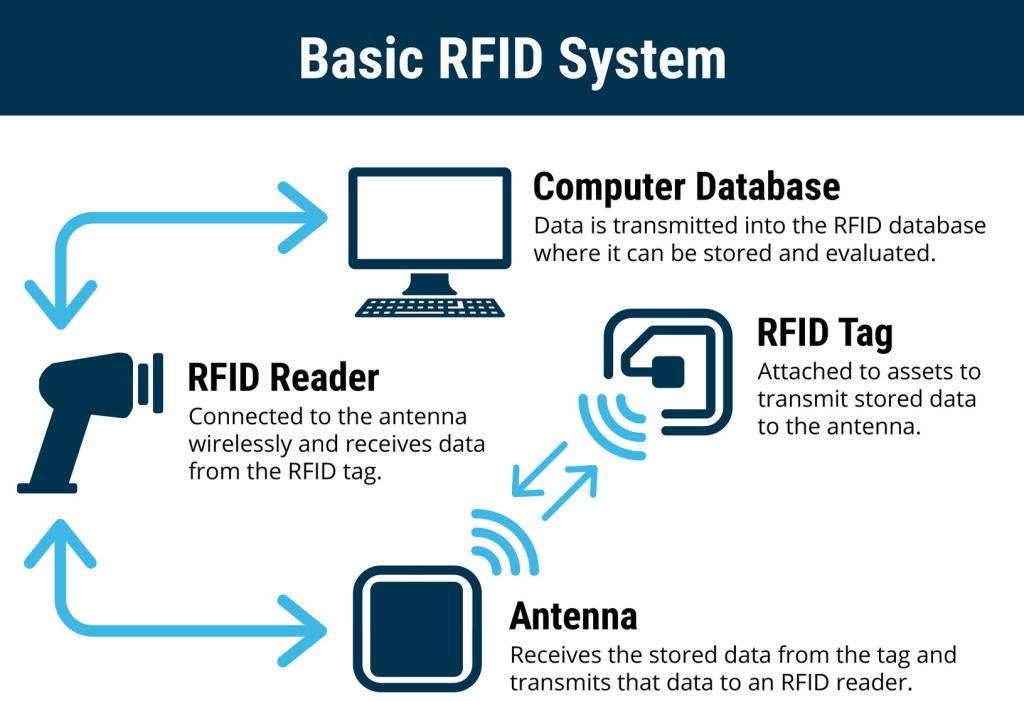

By utilizing technologies like RFID (Radio Frequency Identification) or barcode scanning, businesses can track every product and update inventory levels automatically. This ensures that inventory data is always accurate, up to date, and accessible, no matter where the warehouse is located.

For example, a company using real-time visibility can monitor the status of products across multiple remote warehouses, ensuring that stock levels are optimized and orders are fulfilled promptly, even in distant locations.

2. Faster Decision Making

Real-time visibility allows warehouse managers to make data-driven decisions quickly. By having immediate access to critical information—like stock levels, order statuses, and shipment progress—managers can identify potential issues early on and take corrective actions without delays.

In a remote warehouse scenario, where operational decisions might be made from a distance, having immediate access to real-time data enables quick responses to problems, whether it’s adjusting stock orders, rerouting shipments, or allocating resources more efficiently.

3. Enhanced Operational Efficiency

Remote warehouse management can often lead to inefficiencies, especially when there’s limited insight into day-to-day operations. Real-time visibility optimizes workflows by providing a clear view of processes such as order picking, packing, and shipping.

Managers can use real-time data to monitor the time taken for each task, identify bottlenecks, and adjust processes to ensure smoother operations. Whether it’s ensuring goods are moved faster within the warehouse or tracking the progress of orders, real-time visibility allows for improved coordination and faster execution.

Moreover, integrating real-time visibility tools with automated systems can significantly reduce manual labor and human error, making remote warehouse management more efficient.

4. Improved Customer Satisfaction

In today’s competitive market, customers expect fast, reliable service, and this extends to the fulfillment of orders. Real-time visibility ensures that customers receive accurate delivery times and updates. If there’s a delay, it can be flagged in advance, allowing customer service teams to proactively inform customers and provide solutions.

Remote warehouses with real-time tracking capabilities allow e-commerce businesses to offer faster and more reliable delivery, improving customer satisfaction. Moreover, customers can track their orders in real time, enhancing trust and transparency.

5. Cost Reduction

Managing remote warehouses often involves higher operational costs due to increased complexity. Real-time visibility reduces these costs by improving inventory management, reducing shipping delays, and preventing errors that lead to returns. With instant access to data, businesses can avoid expensive mistakes, like shipping incorrect orders or running out of stock, which can be costly to fix.

Furthermore, real-time visibility allows managers to identify inefficiencies in warehouse operations, such as excess staffing or wasted resources, helping businesses optimize processes and save money.

Real-Time Visibility Tools and Technologies for Remote Warehouses

1. Warehouse Management Systems (WMS)

Warehouse Management Systems (WMS) are essential for managing real-time visibility in warehouses. A WMS provides real-time tracking of inventory, order status, and shipments. By integrating WMS into your warehouse management, you can access real-time data from any location, allowing you to monitor performance and make informed decisions from anywhere.

2. RFID and Barcode Scanning

RFID technology and barcode scanning are widely used in remote warehouses for tracking inventory in real time. With RFID tags or barcodes attached to products, warehouse workers can easily scan items, automatically updating the system with the product’s location, movement, and stock level. This eliminates manual counting and data entry, improving accuracy and reducing labor costs.

3. Cloud-Based Platforms

Cloud-based platforms allow warehouse managers to access real-time data from remote locations, using only an internet connection. These platforms can integrate with your WMS and other logistics tools, providing you with a centralized dashboard to monitor your entire supply chain.

4. IoT (Internet of Things) Devices

IoT devices enable real-time monitoring of warehouse conditions, such as temperature, humidity, and light levels. For industries like pharmaceuticals or food, where product quality is sensitive to environmental factors, IoT sensors provide crucial data to ensure optimal storage conditions. With IoT devices, you can automatically monitor and adjust conditions without the need for manual intervention.

How Postalparcel Improves Real-Time Visibility

For e-commerce businesses managing multiple remote warehouses, working with a logistics partner like Postalparcel can simplify the process. It offers real-time tracking and management services that integrate with your existing WMS, providing centralized visibility across all your warehouses.

Postalparcel’s services help businesses streamline order fulfillment and inventory management, even when warehouses are spread across different regions or countries. With Postalparcel’s real-time visibility tools, managers can track shipments, monitor inventory levels, and adjust shipping routes, ensuring smooth operations and faster deliveries.

One success story involves a company that managed multiple remote warehouses in different countries. By integrating Postalparcel’s logistics services, they gained complete visibility over their entire supply chain, from inventory levels to delivery tracking. This integration reduced delays, improved inventory accuracy, and allowed the company to offer faster delivery times, all of which led to a significant increase in customer satisfaction and sales.

Conclusion

For businesses managing remote warehouses, real-time visibility is no longer optional—it’s essential. The ability to track inventory, monitor order status, and optimize operations in real time can help businesses reduce costs, improve customer satisfaction, and streamline workflows.

By integrating these tools and working with logistics services like Postalparcel, businesses can overcome the challenges of managing distant warehouses, ensuring their operations run smoothly and efficiently. As the global supply chain continues to evolve, real-time visibility will remain a key factor in staying competitive and meeting customer expectations.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua