Reverse Logistics Tracking Secrets That Slash Costs Fast

Reverse logistics tracking is more than a tool—it’s a strategic advantage for modern businesses. Whether you manage a small online store or a large retail operation, being able to track returns, replacements, and repairs with accuracy can cut costs, improve customer satisfaction, and speed up your entire workflow. At Postalparcel, we’ve seen how the right tracking system transforms return management from a headache into a smooth, value-adding process.

Understanding Reverse Logistics Tracking

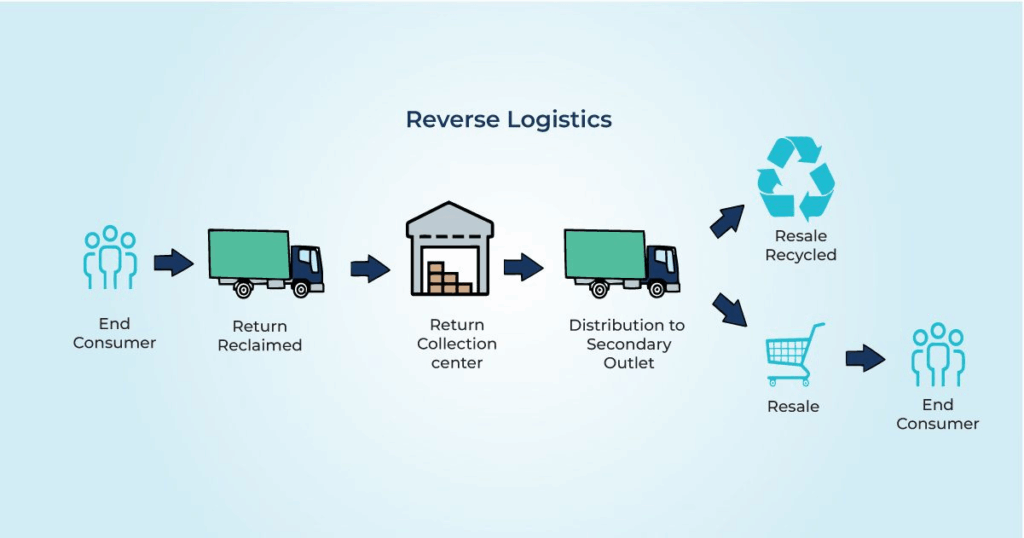

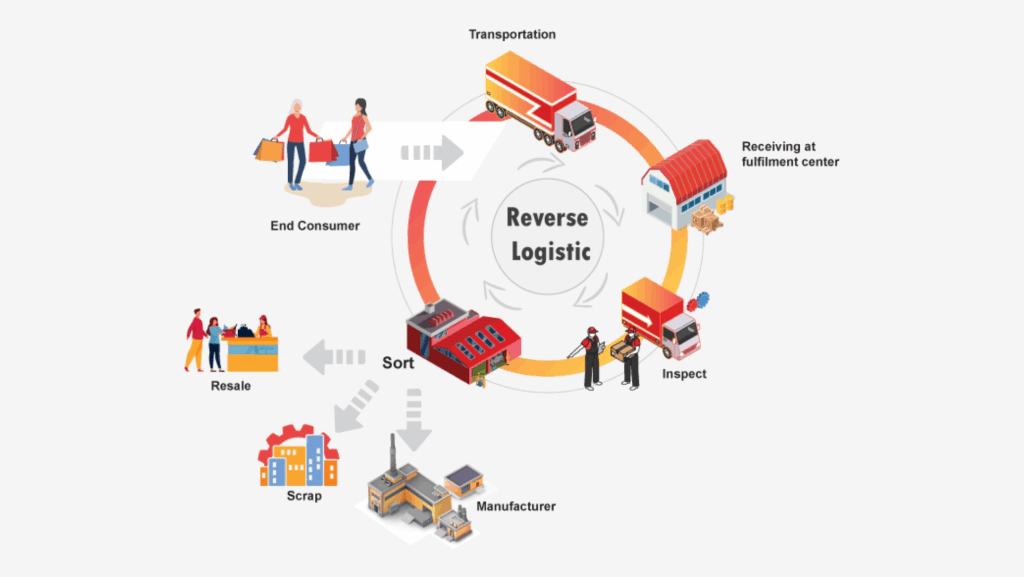

Reverse logistics refers to the movement of goods from customers back to the seller or manufacturer. This includes product returns, warranty repairs, recycling, and refurbishment. Reverse logistics tracking is the process of monitoring and managing these movements in real-time, ensuring every step is visible and well-documented.

Unlike traditional shipping, reverse logistics has more uncertainty. Items may come back in various conditions, from different locations, and with different shipping partners. Tracking systems bridge this gap by providing detailed information—such as package location, expected arrival date, and condition reports—so businesses can act quickly.

The Link Between Reverse Logistics Tracking and OMS Tracking

A strong reverse logistics tracking system works best when integrated with OMS tracking. An Order Management System (OMS) coordinates orders, inventory, and shipping across multiple channels. By linking return data directly to your OMS, you create a single source of truth for all order movements—forward and reverse.

For example, when a customer initiates a return, your OMS tracking updates the order status, your reverse logistics system assigns a return label, and you can instantly see when the item is received and processed. This integration eliminates manual data entry and reduces the risk of mistakes.

Why Businesses Lose Time Without Tracking

Without proper tracking, reverse logistics becomes a guessing game. You might spend days chasing couriers for updates, fielding customer inquiries about the status of their return, or trying to match returned items to original orders. This leads to:

- Longer refund cycles

- Higher customer dissatisfaction

- Increased operational costs

- Inventory mismatches

By implementing reverse logistics tracking, you can cut processing times significantly. For instance, a return that might have taken 10 days to process manually could be completed in 3–4 days with automated updates.

How Reverse Logistics Tracking Saves You Money

The financial benefits of tracking systems go beyond faster processing. Key cost-saving areas include:

1. Reduced Lost Returns

Tracking ensures you know exactly where a returned item is at any time, reducing the risk of lost or misplaced products.

2. Lower Labor Costs

Automation means fewer employees chasing return information manually. Staff can focus on value-added tasks instead.

3. Faster Resale or Recycling

Knowing when a returned item will arrive allows you to inspect, repair, or restock it sooner—keeping inventory fresh and reducing storage costs.

4. Better Data for Supplier Negotiations

Tracking data provides evidence for warranty claims, enabling better discussions with suppliers or manufacturers.

Improving Customer Experience

Customers expect fast, transparent returns. Reverse logistics tracking gives them the same level of visibility they get with outbound deliveries. Real-time updates reassure them their return is moving along, which builds trust and increases the likelihood of repeat purchases.

At Postalparcel, we’ve integrated tracking notifications directly into our customer communication process. This means customers receive automatic updates when their return is picked up, when it reaches our facility, and when the refund or replacement is processed. This level of service not only keeps customers happy but also reduces inbound support requests.

Key Features to Look For in a Reverse Logistics Tracking System

If you’re considering implementing a tracking system, here are the most valuable features:

- Integration with OMS tracking for complete order visibility

- Real-time tracking updates from multiple carriers

- Barcode or QR code scanning for easy return identification

- Automated customer notifications to reduce support tickets

- Data analytics and reporting to optimize return processes

Reverse Logistics Tracking in Action

Imagine a fashion retailer with a high return rate due to size exchanges. Without tracking, staff would spend hours each day locating packages, confirming item conditions, and updating inventory. With reverse logistics tracking, the system automatically logs returns, alerts warehouse staff of incoming items, and syncs with the OMS for immediate inventory updates. The result? A 50% reduction in processing time and a measurable increase in customer satisfaction.

Conclusion

Reverse logistics tracking isn’t just about keeping an eye on packages—it’s about turning a necessary business process into a competitive advantage. By integrating it with OMS tracking, you gain full visibility, reduce costs, and keep customers coming back.

At Postalparcel, we know that returns don’t have to be a loss. With the right tracking tools, they can be an opportunity to strengthen your operations, build trust, and save money. In today’s fast-paced eCommerce world, reverse logistics tracking is no longer optional—it’s essential.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua