Unlock Seamless Reverse Logistics Courier Tracking for Perfect Deliveries!

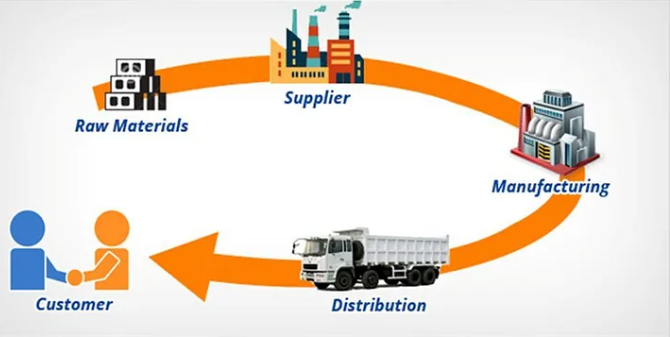

Reverse logistics courier tracking is one of the most complex parts of modern supply chains. Unlike forward logistics, where goods move smoothly from warehouse to customer, the reverse journey often faces unexpected hurdles. Customers want quick returns, businesses need real-time visibility, and couriers must manage multiple checkpoints. Without clear systems, delays, high costs, and poor customer satisfaction follow. This article explores the biggest challenges and explains how to overcome them with practical solutions.

The Growing Importance of Reverse Logistics Tracking

Returns are no longer rare. E-commerce growth has made them a normal part of business. Whether it’s clothing that doesn’t fit or electronics that fail, companies must deal with products moving back. Here, reverse logistics courier tracking ensures that every return is visible, predictable, and efficient. Strong tracking builds trust and cuts waste. It also helps businesses recover value from returned goods, either by reselling, repairing, or recycling.

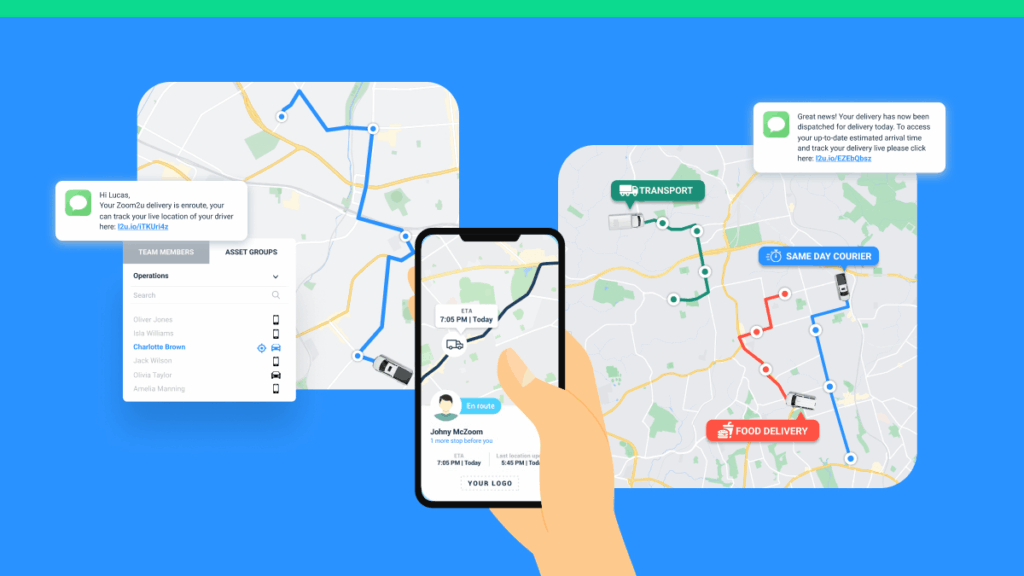

Challenge 1: Lack of Visibility Across Multiple Couriers

Why It Happens

Many companies rely on different couriers across regions. Each courier has its own tracking system. When data isn’t unified, it’s hard to get a full picture of where returned items are.

Solution

- Use centralized tracking platforms that collect courier data into one dashboard.

- Apply APIs to connect different systems and show real-time updates.

- Work with logistics partners like Postalparcel that provide end-to-end visibility, regardless of courier.

Challenge 2: Slow Return Processing

Why It Happens

Returns often move more slowly than outbound deliveries. Couriers prioritize forward shipments, leaving reverse goods waiting. This creates frustration for customers.

Solution

- Offer prepaid return labels with priority codes.

- Arrange dedicated return pickup schedules with couriers.

- Use automation to notify customers at each stage of the return process.

Challenge 3: High Costs in Reverse Movements

Why It Happens

Reverse shipments are less predictable and often smaller in volume. This makes them expensive. Couriers must handle scattered packages, which adds cost.

Solution

- Consolidate returns into bulk shipments before sending to warehouses.

- Negotiate with couriers for special reverse logistics rates.

- Apply smart routing to send goods to the nearest processing center, not always back to the main hub.

Challenge 4: Unclear Condition of Returned Items

Why It Happens

Once a product leaves a customer, businesses often don’t know the condition until it arrives. This delay slows decisions about repair, resale, or disposal.

Solution

- Request customers to upload return photos before shipping.

- Use smart packaging with QR codes for quick condition notes.

- Partner with couriers who can provide item inspection at collection.

Challenge 5: Customer Experience Gaps

Why It Happens

Many customers complain they don’t know where their returned package is. Lack of clear tracking creates doubt about refunds or replacements.

Solution

- Send automatic tracking updates by email or SMS.

- Create self-service portals for customers to check return status.

- Show estimated refund or replacement times clearly during the return process.

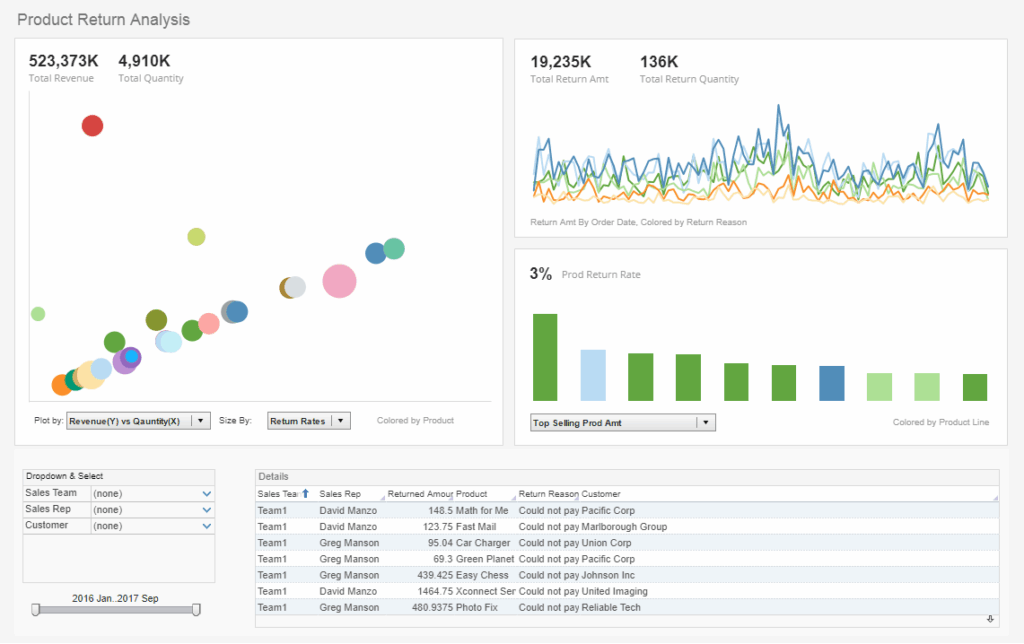

Challenge 6: Data Fragmentation and Manual Work

Why It Happens

Without strong digital systems, companies rely on spreadsheets or manual updates. This causes errors and wasted time.

Solution

- Introduce reverse logistics tracking software that integrates with warehouse and courier systems.

- Use data analytics to forecast return trends and spot problems early.

- Train teams to manage one source of truth instead of multiple manual records.

Challenge 7: Sustainability Pressures

Why It Happens

Returns generate extra transport emissions and packaging waste. Businesses face rising pressure to manage reverse flows responsibly.

Solution

- Optimize routes to reduce transport emissions.

- Reuse packaging for return journeys.

- Build recycling programs for products that can’t be resold.

- Highlight green return processes as part of the brand promise.

How Reverse Logistics Courier Tracking Delivers Value

With proper systems, businesses turn challenges into opportunities:

- Faster Refunds – Customers trust brands that handle returns quickly.

- Lower Costs – Smarter routing reduces unnecessary transport.

- Sustainability Gains – Efficient reverse flows reduce waste.

- Better Insights – Tracking data reveals trends in product quality and customer needs.

By addressing these points, companies not only solve logistical problems but also strengthen long-term customer loyalty.

Why Postalparcel Makes a Difference

Managing reverse logistics alone is complex. With Postalparcel, businesses can connect couriers, unify tracking, and manage both forward and reverse flows. The platform is built to handle global shipping challenges, making it easier to provide transparency to customers and reduce costs. By focusing on real-time reverse logistics courier tracking, Postalparcel helps brands stay ahead in a competitive market.

Conclusion

Reverse logistics courier tracking is more than an operational task. It is a key factor in customer trust, cost control, and sustainability. The challenges are real: poor visibility, slow processing, high costs, and fragmented data. But with the right tools, clear strategies, and strong partners, every hurdle can be overcome. Businesses that invest in reverse logistics tracking today will build a stronger foundation for the future of e-commerce and global trade.

FAQs

Q1: Why is reverse logistics courier tracking harder than forward tracking?

Because reverse flows are less predictable, involve multiple couriers, and lack standard processes, they make visibility harder to achieve.

Q2: How can small businesses improve reverse logistics tracking?

They can use third-party platforms that integrate courier data and provide customer-facing tracking pages without large infrastructure costs.

Q3: Does better reverse logistics tracking reduce return costs?

Yes. By optimizing routes, consolidating shipments, and using smart analytics, businesses can cut costs while improving customer satisfaction.

Q4: What happens if my tracked parcel is not delivered?

If your tracked parcel shows no delivery after the expected time, first check the tracking updates carefully. Sometimes parcels are delayed due to customs, weather, or courier backlogs. Contact the courier or the seller to open an investigation.

Q5: What do I do if my package never arrives?

If your package never arrives, report the issue to both the courier and the retailer. Most companies require a formal claim within a certain time frame. Keep your order confirmation and tracking details ready to speed up the process.

Q6: Can you get money back if a package is stolen?

Yes, in many cases you can. If the courier confirms delivery but the package is stolen, contact the seller to request a replacement or refund. Some couriers and retailers offer insurance or buyer protection that covers theft claims.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua