Reverse Logistics Tracking Transforms Supply Chains Fast

Reverse logistics tracking is no longer an afterthought in supply chains. It has become a vital function that allows businesses to handle returns, repairs, recycling, and product recalls with precision. Companies that fail to manage reverse logistics effectively risk higher costs, unhappy customers, and wasted resources. This guide explores the role of reverse logistics tracking, its benefits, challenges, and the ways modern tools are reshaping reverse logistics in supply chain management.

What Is Reverse Logistics Tracking?

Reverse logistics tracking refers to the process of monitoring goods as they move from the end customer back to the seller, manufacturer, or recycler. Unlike forward logistics, which delivers products to customers, reverse logistics deals with returns, exchanges, and product recovery. This part of the supply chain has grown in importance due to the rise of e-commerce, frequent product recalls, and growing awareness of sustainability.

Core Functions of Reverse Logistics Tracking

- Returns and refunds processing, ensuring customers quickly receive replacements or refunds

- Repair and refurbishment management, extending the lifecycle of valuable products

- Recycling and waste reduction, keeping harmful materials out of landfills

- Warranty claim handling, giving businesses visibility into defect trends

- Recall management, which demands speed and traceability to protect consumer safety

With tracking, businesses gain visibility into every stage of these processes, ensuring nothing gets lost or delayed and allowing them to make smarter, data-driven decisions.

Why Reverse Logistics Matters in Supply Chain Management

Customer Expectations

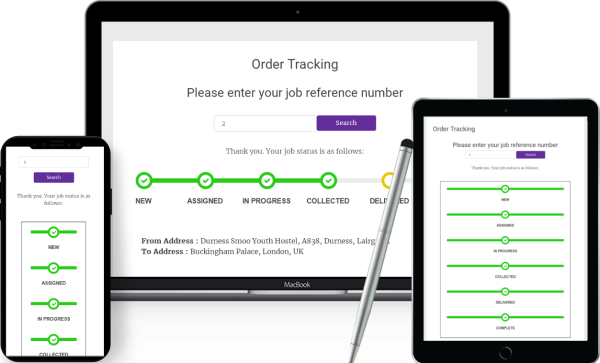

Customers today demand more than just fast delivery. They also expect returns to be simple, transparent, and quick. Reverse logistics tracking makes this possible by offering status updates at each stage of the return journey. This visibility builds trust, reassures buyers that their money is safe, and increases the likelihood of repeat purchases.

Business Efficiency

For companies, reverse logistics tracking reduces operational waste, speeds up decision-making, and improves inventory accuracy. It ensures returned products re-enter the supply chain quickly—either for resale, repair, or recycling—reducing the chance of stock shortages and cutting down on unnecessary storage costs.

Sustainability Goals

More and more companies are committing to sustainability targets. Tracking ensures businesses know exactly where their returned items end up, allowing them to demonstrate accountability. Whether an item is refurbished, recycled, or responsibly discarded, tracking provides data that supports environmental reporting and enhances corporate responsibility.

Benefits of Reverse Logistics Tracking

For Businesses

- Better cost control through reduced waste and fewer lost returns

- Faster turnaround of returned goods into resale stock, recovering value quickly

- Reduced fraud by verifying the authenticity and legitimacy of returns

- Improved data insights to forecast future returns and refine product design

For Customers

- Real-time visibility on the return process, reducing anxiety over refunds

- Confidence in receiving refunds or replacements quickly and without disputes

- Transparent communication that shows the company values their satisfaction

Challenges in Reverse Logistics Tracking

Complex Returns Networks

Unlike forward logistics, reverse logistics involves multiple and unpredictable touchpoints. A product might move through courier services, warehouses, testing centers, repair hubs, and recyclers before reaching its final destination. Coordinating these steps is difficult, and without tracking, companies risk losing sight of where an item is at any given time.

Data Integration Issues

Many businesses use fragmented systems that don’t communicate well. If reverse tracking platforms are not integrated with warehouse management, CRM, and transport systems, visibility gaps appear. These gaps make it hard to provide accurate updates to customers and limit the ability of managers to optimize returns.

Cost Management

Returns are expensive. They involve transportation, inspection, restocking, and sometimes disposal. Without efficient tracking, these costs grow because items take longer to process, get lost in transit, or require extra labor. Strong reverse logistics tracking minimizes these risks and ensures cost control.

Technology Shaping Reverse Logistics Tracking

RFID and Barcodes

RFID tags and barcodes are low-cost, highly effective solutions that make it simple to scan and update the status of returns instantly. Each scan creates a data point that feeds into central systems, allowing managers to track movement in real time.

IoT Devices

Sensors placed on shipments provide real-time condition data, such as temperature, humidity, and location. This technology ensures that sensitive or fragile returns are handled correctly, reducing losses from damage.

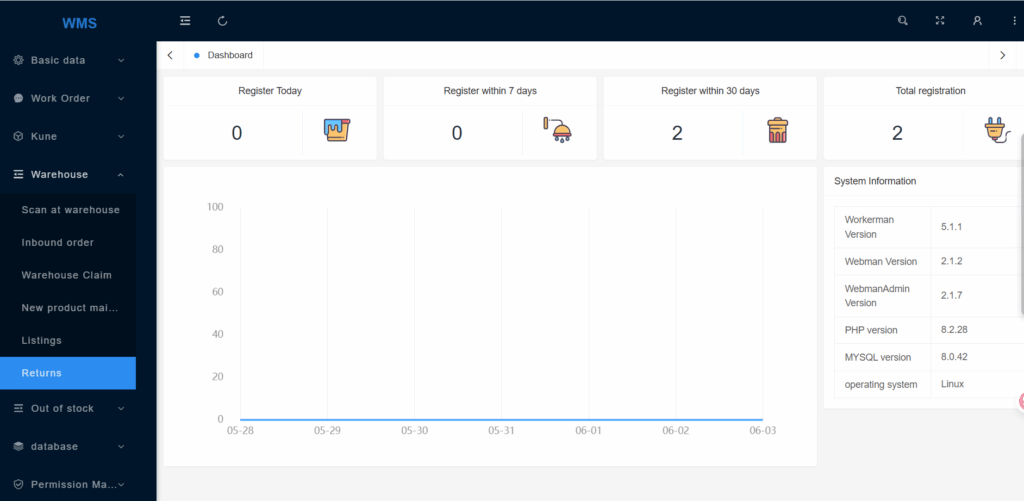

Cloud-Based Platforms

Platforms like postalparcel unify data from multiple logistics partners, warehouses, and carriers into one dashboard. This centralization offers businesses full visibility of the reverse journey, making management far simpler.

AI and Predictive Analytics

Artificial intelligence can analyze return trends, forecast demand for spare parts, and help businesses prepare for peak return seasons. Predictive analytics also assists in optimizing staff allocation and storage space, improving overall efficiency.

Reverse Logistics Tracking vs Forward Logistics

- Forward Logistics: The movement of products from suppliers or manufacturers to customers, focusing on fast and accurate deliveries.

- Reverse Logistics: The movement of products from customers back to businesses for returns, recycling, or repair.

Tracking in forward logistics emphasizes speed and accuracy of delivery. Reverse logistics tracking emphasizes speed of returns, quality inspections, and reprocessing. The latter is often more complex because businesses cannot always predict when, how, or in what condition products will be returned.

Best Practices for Reverse Logistics Tracking

1. Standardize Processes

Having clear, documented steps for handling returns and repairs makes tracking more consistent. Standardization avoids confusion and ensures data is recorded uniformly.

2. Use Centralized Platforms

A unified system eliminates data silos and ensures all stakeholders—from carriers to warehouse staff—see the same information in real time.

3. Communicate Clearly with Customers

Returns communication should be proactive. Regular updates via SMS, email, or online portals reduce customer inquiries and improve satisfaction.

4. Measure KPIs

Metrics like return cycle time, processing costs, recovered value, and customer satisfaction help measure performance and identify areas for improvement.

5. Partner with Reliable Carriers

Carriers with strong digital capabilities ensure that every stage of the reverse journey is tracked, minimizing uncertainty.

The Future of Reverse Logistics in Supply Chain Management

Reverse logistics is evolving from a cost-heavy necessity into a strategic differentiator. With online sales driving higher return volumes, companies are no longer treating reverse flows as a burden but as an opportunity to recover value, strengthen customer loyalty, and support sustainability goals. Businesses that invest in reverse logistics tracking will enjoy greater agility, improved efficiency, and stronger brand reputation in the years ahead.

Why Choose Postalparcel for Reverse Logistics Tracking

Postal parcel delivers advanced solutions for reverse logistics tracking tailored to modern supply chains. Its platform connects retailers, warehouses, and carriers, providing complete visibility and efficiency. By using postalparcel, businesses can streamline operations, reduce costs, and improve customer trust. The result is a system that not only manages returns but turns them into opportunities for growth.

Conclusion

Reverse logistics tracking is an essential part of modern supply chains. It allows businesses to manage returns efficiently, cut unnecessary costs, and maintain transparency with customers. From RFID to predictive analytics, technology is making it easier than ever to transform reverse logistics into a strategic advantage. With postalparcel providing innovative solutions, businesses can turn the challenge of returns into a driver of value and sustainability.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua