Reverse Logistics KPIs: Boost Returns with Postalparcel

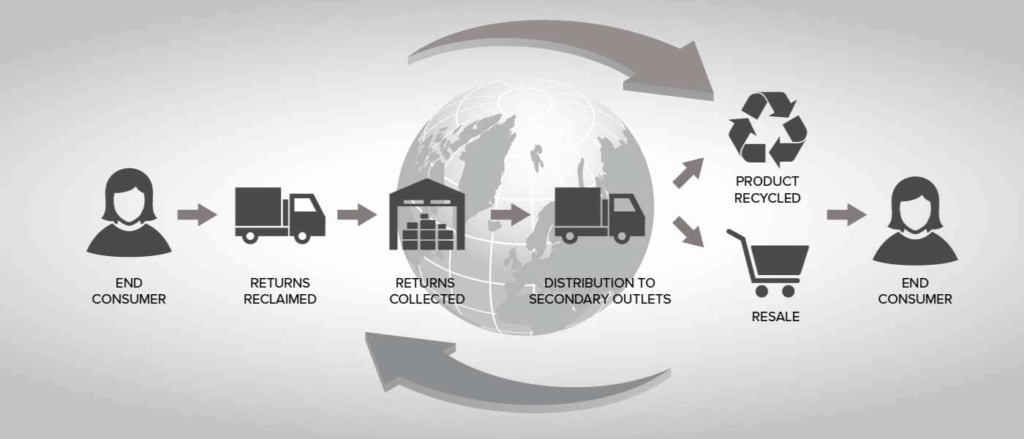

Reverse logistics plays a vital role in how companies handle returns, repairs, and product recycling. To understand whether a reverse logistics tracking system is performing well, you must measure its results. Key performance indicators (KPIs) reveal if the process is saving money, saving time, and keeping customers happy. Without clear KPIs, it is impossible to see which parts of the return process are working and which areas need improvement. This guide explains the most important KPIs to follow and shows how a trusted service like Postalparcel can make this job easier and more effective.

Why KPIs Matter in Reverse Logistics

KPIs are more than numbers. They give managers the full picture of how the reverse logistics process is performing. By turning complex operations into measurable data, these indicators help companies spot problems early, improve efficiency, and reduce unnecessary costs. Strong KPI tracking also improves customer satisfaction because customers feel confident that returns will be processed quickly and accurately.

Core Benefits of Measuring KPIs

- Identify weak points before they create delays or customer complaints

- Improve efficiency across every stage of the return process

- Lower operational costs by finding and removing bottlenecks

- Increase customer trust and brand loyalty through reliable return handling

- Provide data for future planning and smarter inventory management

Key KPIs for Reverse Logistics Tracking

1. Return Rate

How to Use It

- Monitor return trends monthly to catch sudden spikes that indicate product issues

- Compare return rates across product categories to find recurring problems

- Use customer feedback to discover patterns in why items are returned

2. Time to Process Returns

This KPI measures how long it takes to receive, inspect, and restock or dispose of a returned product. Shorter processing times mean lower labor costs and a better experience for the customer waiting for a refund or replacement.

Tips to Improve

- Use automation tools to speed up check-ins and scanning of returned items

- Provide clear and simple instructions for customers to reduce shipping errors

- Train staff to handle returns efficiently and consistently

3. Cost per Return

Cost per return calculates the total cost of handling each item that comes back. It includes shipping fees, labor, inspection, restocking, and sometimes recycling costs. Knowing the true cost helps companies control expenses and set accurate budgets.

Ways to Cut Costs

- Partner with reliable carriers for better shipping rates and faster processing

- Implement bulk return policies when suitable to reduce per-item costs

- Use data to identify products with high return costs and improve their design or packaging

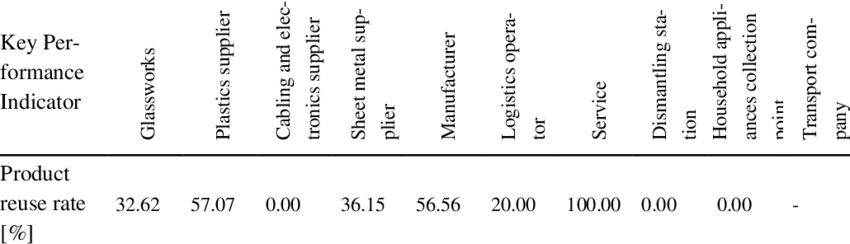

4. Recovery Rate

The recovery rate shows how much value is regained from returned items. This value can come from resale, refurbishment, or recycling. High recovery rates mean the business is turning returns into a source of profit or savings.

Action Points

- Track resale income from returned goods to measure financial recovery

- Analyze which items are best suited for repair or repackaging for resale

- Explore recycling programs that convert waste into new materials or products

5. Customer Satisfaction with Returns

Customer satisfaction is not only about sales but also about what happens when a product does not meet expectations. A smooth return process builds loyalty and encourages repeat purchases.

Measurement Methods

- Collect ratings through post-return surveys or automated emails

- Monitor repeat purchase rates from customers who have made returns

- Review online reviews and social media comments for feedback on the return process

6. Reverse Logistics Cycle Time

Cycle time measures the complete journey from when a customer requests a return to the final resolution. Shorter cycles mean better service and lower costs.

Steps to Monitor

- Map each stage of the return process and set time targets for each

- Use real-time tracking to find slow points and fix them quickly

- Provide regular updates to customers to maintain trust and transparency

Supporting KPIs for Deeper Insights

Inventory Accuracy after Returns

Inventory accuracy shows how well returned items are recorded back into stock. High accuracy ensures that the next order can be fulfilled correctly without delays or stockouts.

Rate of Defective Returns

This metric measures how many returns are caused by product defects versus customer preferences. A high defect rate signals quality control issues that need immediate attention.

Environmental Impact Metrics

Sustainability matters more every year. Tracking the percentage of returned items that are recycled or reused helps protect brand reputation and meet environmental regulations.

How Postalparcel Helps Track KPIs

A service like Postalparcel provides advanced tools and technology for reverse logistics tracking. Their platform gives real-time visibility, detailed reporting, and powerful analytics that make KPI measurement simple. Businesses using Postalparcel gain a complete view of return rates, costs, and customer feedback without needing to build their own complex systems. This saves time and allows managers to focus on making decisions instead of gathering data.

Steps to Implement KPI Tracking

- Define Goals: Decide which KPIs match your business needs and customer expectations.

- Collect Data: Use automated systems or integrated software to gather accurate return information.

- Analyze Results: Review data regularly to identify trends and areas for improvement.

- Take Action: Adjust processes to improve weak areas and reduce costs.

- Review Often: Update KPIs as your business grows and customer needs change.

Best Practices for Ongoing Improvement

- Set realistic and measurable targets for each KPI.

- Share reports with your team to keep everyone aligned and accountable.

- Invest in technology that integrates smoothly with your existing systems.

- Benchmark results against industry standards to stay competitive.

- Offer training to staff so they understand how their actions affect KPIs.

Conclusion

Tracking the right KPIs is the key to successful reverse logistics management. Metrics such as return rate, processing time, cost per return, and recovery rate reveal how well your system performs and where it needs attention. Customer satisfaction and environmental impact provide a broader view of long-term success. By using reliable services like Postalparcel to monitor and analyze these indicators, companies can cut costs, speed up returns, and deliver a better customer experience. A strong KPI strategy transforms reverse logistics from a challenge into a powerful advantage for growth.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua