Maximize Efficiency with Reverse Logistics & KPIs

Reverse logistics in supply chain management is more than simply handling returns. It is a strategy that saves money, improves customer satisfaction, and builds a sustainable operation. From returned goods to product recycling, every step of the reverse flow provides valuable data and business opportunities. Companies using advanced solutions like Postalparcel and its reverse logistics tracking system gain control over costs, inventory, and customer trust.

This guide explains the main benefits of reverse logistics in supply chain management and how to apply these ideas to achieve measurable results.

Lowering Operational Costs

Cutting Waste and Reducing Expenses

A well-designed reverse logistics process prevents unnecessary waste and lowers expenses. Tracking every return helps companies identify where money is lost and where operations can improve.

Key actions include:

- Consolidating shipments to reduce transport costs per item

- Automating check-ins and inspections to cut labor costs

- Negotiating better shipping rates with reliable carriers

With Postalparcel, reverse logistics tracking provides real-time data on these cost-saving measures, helping management make informed decisions quickly.

Improving Budget Planning

Understanding the true cost per return allows companies to create more accurate budgets. This helps in planning for seasonal peaks or sudden spikes in returns, ensuring resources are allocated efficiently without overspending.

Strengthening Customer Trust

Making Returns Hassle-Free

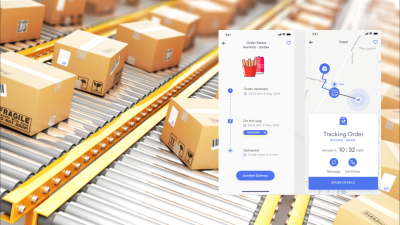

A smooth return process builds loyalty. Customers who can return products easily are more likely to buy again. Reverse logistics in supply chain management ensures that every return is tracked and handled promptly.

Customer-focused improvements include:

- Real-time updates on return status

- Clear instructions to avoid shipping errors

- Faster refunds and replacements

Postalparcel enhances this with detailed reverse logistics tracking, giving customers confidence and encouraging repeat purchases.

Encouraging Repeat Business

When customers trust the return process, they often become repeat buyers. This loyalty creates steady revenue and strengthens the brand’s reputation.

Boosting Sustainability

Reducing Environmental Impact

Sustainability is a key expectation in modern supply chains. Reverse logistics in supply chain management helps companies reuse packaging, refurbish products, and recycle materials.

Environmental benefits include:

- Lowering carbon emissions through optimized transport routes

- Tracking recycled or refurbished products accurately

- Reducing landfill waste by recovering usable materials

Using Postalparcel for reverse logistics tracking ensures companies can measure and report these eco-friendly achievements.

Meeting Regulatory Standards

Many regions now require businesses to prove sustainable practices. Detailed tracking makes it easier to comply with environmental regulations and demonstrate responsibility to customers and stakeholders.

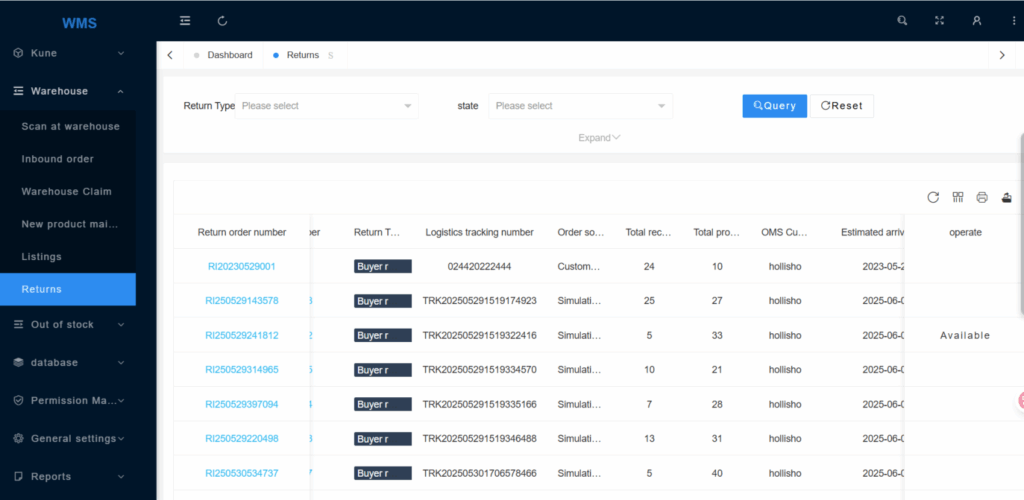

Improving Inventory Management

Maintaining Accurate Stock Levels

Returned products directly affect inventory. Without careful monitoring, errors can cause overstocking or shortages. Reverse logistics in supply chain management ensures returned goods are quickly inspected and recorded.

Inventory advantages include:

- Real-time visibility of returned items

- Faster restocking of resellable products

- Better forecasting for future demand

Postalparcel provides reverse logistics tracking that keeps inventory records accurate and up to date.

Preventing Stockouts

Accurate reverse flow data helps prevent stockouts, ensuring that popular products remain available for customers even during peak demand.

Gaining a Competitive Edge

Data-Driven Strategy

Companies that master reverse logistics gain valuable insights into customer behavior and product quality. This information helps in product design, marketing strategies, and overall business planning.

Competitive strengths include:

- Stronger brand reputation from eco-friendly and reliable service

- Faster response to market changes and product defects

- More efficient supply chain planning based on real return data

Reverse logistics tracking from Postalparcel provides the analytics needed to stay ahead of competitors.

Building Long-Term Resilience

A supply chain that can quickly adapt to product returns and recycling is more resilient during market disruptions or economic downturns.

Enhancing Financial Recovery

Turning Returns into Value

Returned products are not just losses. With the right process, they can be refurbished, resold, or recycled to recover value.

Ways to maximize recovery:

- Repair and repackage items for resale

- Sell refurbished products at discounted rates

- Convert waste into new materials through recycling

Tracking recovery rates through reverse logistics ensures companies capture every opportunity to regain value.

Steps to Implement Effective Reverse Logistics

Implementing a successful reverse logistics strategy requires careful planning and continuous improvement. Here’s a deeper look at the steps businesses should follow to ensure their reverse logistics operations are efficient and cost-effective.

1. Define Clear Goals

The first step in any effective reverse logistics process is to define clear and measurable goals. These goals will guide your strategy and help you stay focused on what matters most to your business. Start by identifying the Key Performance Indicators (KPIs) that best reflect the success of your reverse logistics operations. Some important KPIs include:

- Return Rate: How often customers return products, and if certain product categories have higher return rates.

- Processing Time: The time it takes to receive, inspect, and either restock or dispose of returned products. Shorter processing times lead to better efficiency and reduced labor costs.

- Cost per Return: The total cost associated with processing each return, including shipping, labor, inspection, restocking, and recycling.

By identifying these KPIs, businesses can set specific targets that align with their broader operational goals. Setting clear expectations from the outset helps teams focus on areas that will make the biggest impact on efficiency and cost control.

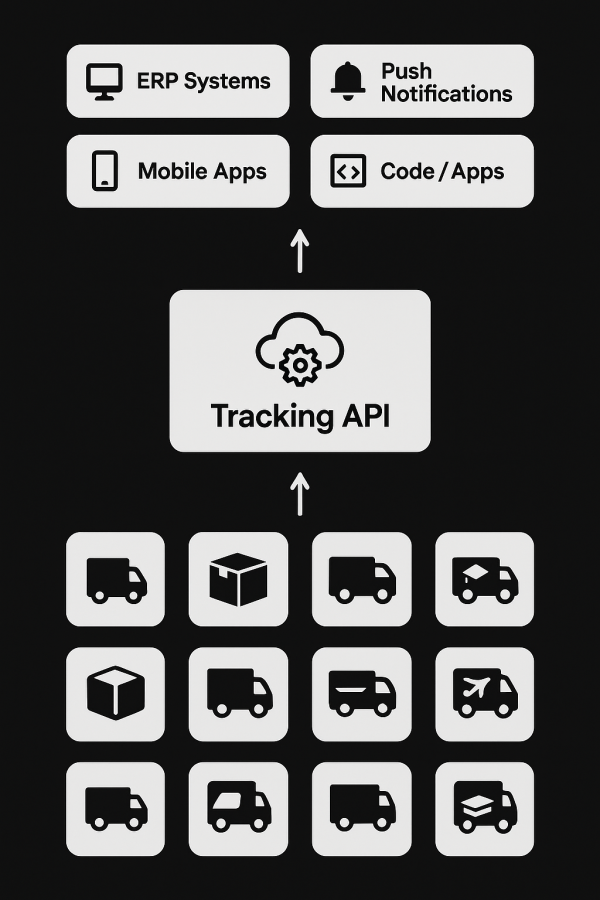

2. Automate Data Collection

One of the biggest advantages of modern reverse logistics is the ability to automate data collection. Using tools like Postalparcel, businesses can capture accurate and real-time return data, ensuring that every aspect of the reverse process is tracked. Automation offers several key benefits:

- Real-Time Visibility: With automation, businesses can track the status of returned products in real-time, giving them the ability to make quick decisions when issues arise.

- Consistency and Accuracy: Automated systems help eliminate human error, ensuring that each return is processed and recorded accurately, leading to more reliable data.

- Efficiency: By automating tasks like product check-ins, inspections, and data entry, businesses can streamline their return processes, reducing labor costs and increasing speed.

With automated data collection, businesses can gain a clearer picture of their reverse logistics operations and make more informed decisions.

3. Analyze and Act

Once data is collected, it’s essential to regularly review and analyze performance reports. These reports offer valuable insights into trends, bottlenecks, and inefficiencies in the return process. Key actions during this stage include:

- Spotting Trends: Identifying recurring issues, such as certain products or categories with a higher return rate, helps businesses address the root cause of returns, such as product quality or marketing misalignment.

- Identifying Bottlenecks: Analyzing return processing times helps identify areas where the process can be delayed, whether due to logistics, inventory issues, or labor constraints. Once identified, businesses can address these bottlenecks by optimizing workflows or introducing automation.

- Making Adjustments: Based on data insights, businesses should adjust their processes, whether it’s speeding up inspections, renegotiating return shipping rates with carriers, or refining customer service protocols.

Regular analysis empowers businesses to stay proactive and improve their operations continuously.

4. Improve Continuously

Reverse logistics should never be static. Businesses must continuously evaluate and adjust their processes to meet evolving market needs and customer expectations. Key practices for continuous improvement include:

- Updating KPIs: As market conditions and business goals change, your KPIs should evolve. For example, as your business grows or product lines expand, you may need to set new benchmarks for return rates or processing times.

- Customer Feedback: Customer satisfaction plays a significant role in reverse logistics. Gathering feedback through surveys or post-return emails provides valuable information on how the return process can be improved to meet customer expectations.

- Process Refinement: Analyze performance data regularly to spot areas of inefficiency. Implementing small changes or investing in new technologies like AI-driven inventory management or predictive analytics can help refine your process.

- Staff Training: Ensure that employees are properly trained in handling returns efficiently and adhering to new process changes. This helps maintain consistent performance and increases employee satisfaction.

By adopting a culture of continuous improvement, businesses can stay ahead of the competition and ensure their reverse logistics operations remain agile, cost-effective, and customer-centric.

Conclusion

Reverse logistics in supply chain management delivers clear, measurable benefits: lower costs, happier customers, accurate inventory, and a smaller environmental footprint. Companies that combine best practices with powerful reverse logistics tracking from Postalparcel turn returns into opportunities for profit and growth. By investing in this strategy, any business can strengthen its supply chain and secure long-term success.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua