How Cross-Border eCommerce Can Use Global Tracking for Light Inventory Management

Explore Postalparcel’s global delivery and tracking solutions.

Cross-border eCommerce often faces challenges such as long transit times, unpredictable customs processes, and inconsistent logistics updates. These issues can easily lead to inventory problems—too much stock in one region, not enough in another, and rising storage costs.

Global Tracking helps fix these problems by providing real-time visibility of international shipments. It allows businesses to manage inventory precisely, reducing excess stock while ensuring smooth global delivery. This approach is known as light inventory management, where efficiency replaces overstocking.

Why is Light Inventory Difficult for Cross-Border eCommerce?

Operating across countries presents unique logistics challenges that make managing stock more difficult.

Key challenges include

- Shipping and customs clearance delays result in extended lead times.

- High warehousing costs from maintaining large stock buffers.

- Lack of visibility due to different carriers and tracking systems.

- Unpredictable regional demand is making stock forecasting difficult.

Without accurate tracking data, sellers often rely on estimates rather than facts. This typically results in misjudged inventory levels and increased operational costs.

What Is Global Tracking and How Does It Work

Global Tracking is a unified system that gathers shipment data from multiple countries, carriers, and logistics partners. It keeps businesses informed about the exact location and status of their goods at all times.

Main functions

- Provides real-time tracking for all shipments worldwide.

- Combines carrier data into a single dashboard.

- Sends early alerts for possible delays or customs issues.

- Integrates with ERP and warehouse management systems to sync updates automatically.

With this visibility, companies can balance stock more efficiently and respond faster to changes in demand or logistics conditions.

How Global Tracking Supports Light Inventory

Light inventory means maintaining a lean stock while still being able to fulfill orders quickly. Worldwide Tracking helps achieve this balance through transparency and automation.

Real-Time Updates for Smarter Stock Decisions

Each shipment update automatically adjusts inventory levels. Sellers can track exactly when goods will arrive and plan their next restock accordingly.

Example:

A merchant in China shipping to Germany can see that their goods are two days from arrival. They can avoid overstocking and free up capital for other business needs.

Benefits

- Reduced safety stock requirements

- More accurate restocking plans

- Lower cash flow pressure

Predictive Planning Based on Tracking Data

Global Tracking collects long-term data on routes, carriers, and customs performance. Over time, this data helps predict delays and optimize logistics choices.

Businesses can use it to

- Identify slower routes and plan earlier shipments

- Choose carriers with higher reliability

- Adjust reorder points to real-world transit times

These insights help maintain a steady stock flow without overbuying.

Multi-Warehouse Coordination

Many cross-border sellers operate multiple warehouses across the globe. Worldwide Tracking connects them all under one system, showing exactly where goods are in transit or storage.

Outcomes

- Real-time stock synchronization between warehouses

- Easier redistribution of goods to high-demand areas

- Reduced risk of stockouts or overstocking

Eliminating Dead Inventory

Global Tracking highlights which products move slowly in certain regions. Businesses can relocate these items to faster-selling areas, preventing waste and improving turnover.

Example

If sales drop in the UK but rise in Spain, a seller can transfer inventory accordingly, guided by accurate tracking data.

How Global Tracking Reduces Risk

Cross-border operations come with many uncertainties. Global Tracking turns potential risks into manageable situations.

Early Warnings for Delays

Tracking systems alert businesses the moment a delay occurs—whether at customs or during transit. This allows immediate action, such as rerouting shipments or notifying customers.

Reliable Partner Evaluation

Each tracking event builds a performance history for carriers and suppliers. Businesses can identify the most dependable partners based on delivery speed and consistency.

More innovative Stock Planning During Peak Seasons

Before major sales events, tracking data helps predict real transit times. Sellers can plan shipments earlier and avoid last-minute air freight or high safety stock.

Integrating Global Tracking with Inventory Systems

The real power of Global Tracking lies in its integration. When tracking data is integrated directly with inventory management systems, businesses gain end-to-end visibility.

Integration process

- Connect tracking feeds from all carriers.

- Sync shipment data with ERP or warehouse software.

- Automate stock level updates when goods move.

Key advantages

- Inventory updates in real time without manual entry.

- Automatic restock triggers when shipments near delivery.

- Unified insights across logistics, sales, and fulfillment.

This level of automation enables eCommerce businesses to operate efficiently, even with limited staff.

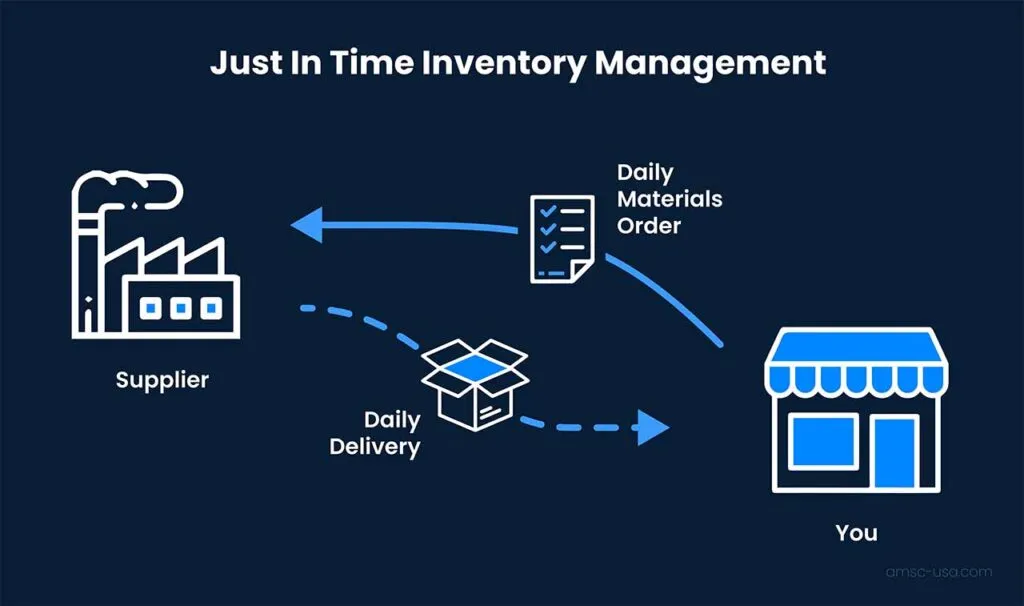

Enabling a Just-in-Time Inventory Model

Light inventory often follows a Just-in-Time (JIT) approach—keeping minimal stock while ensuring reliable delivery. Worldwide Tracking supports this model by giving precise, live updates.

It helps by

- Predicting arrival times for incoming goods.

- Reducing buffer stock while maintaining service levels.

- Shortening cash-to-cash cycles.

Example

A U.S. eCommerce brand selling in Asia reduced stock levels by 25% after implementing Global Tracking. Consistent delivery data enabled them to restock with confidence, rather than holding unnecessary inventory.

Financial outcomes

- Less capital tied up in goods

- Lower risk of excess stock

- Improved scalability and profitability

Steps to Implement Global Tracking

Implementing Global Tracking can be done gradually.

Step 1: Map Your Logistics Network

List all suppliers, carriers, and warehouses. Identify where tracking data is missing or inconsistent.

Step 2: Choose a Multi-Carrier Platform

Utilize a Global Tracking solution that supports international carriers and seamlessly integrates with your existing systems.

Step 3: Automate Stock Synchronization

Ensure that every shipment update automatically changes the stock status. This keeps all systems aligned.

Step 4: Analyze and Improve

After collecting several months of data, review average transit times, bottlenecks, and carrier performance. Adjust your inventory strategy accordingly.

Step 5: Keep Customers Informed

Display real-time tracking on your website and notifications. Transparency builds confidence and reduces support inquiries.

The Future of Global Tracking

Advances in technology are making Global Tracking more intelligent and accurate.

- AI tools predict potential customs or route delays before they happen.

- IoT sensors provide detailed information on shipment conditions, including temperature and impact.

- Automation systems connect tracking data directly to sales forecasts for faster decision-making.

These innovations are pushing cross-border eCommerce toward greater efficiency and more intelligent inventory control.

Conclusion

Global Tracking is transforming how cross-border eCommerce manages inventory. It enables sellers to monitor shipments worldwide, plan restocks precisely, and operate with minimal stock without risking shortages.

For global sellers seeking to reduce costs and enhance delivery performance, integrating Global Tracking into inventory management is a practical and effective solution.

Discover how Postalparcel simplifies Global Tracking for your business.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua