What Happens When Order Fulfillment Goes Wrong in Logistics

Accurate order fulfillment in logistics is one of the most important factors that determine a company’s reputation and profitability. When fulfillment errors occur, they don’t just affect one shipment — they ripple through the entire supply chain, impacting customer trust, operational efficiency, and long-term growth. Understanding the consequences of these errors helps businesses recognize the importance of accuracy in logistics and develop systems to prevent future mistakes.

The Importance of Accurate Order Fulfillment in Logistics

Order fulfillment is the process of receiving, processing, and delivering a customer’s order. In logistics, accuracy means ensuring that the right product reaches the right customer at the right time. When this process works smoothly, it builds customer confidence and strengthens brand loyalty. However, when something goes wrong, the damage can be both immediate and long-lasting.

Accurate order fulfillment is crucial because:

- It directly affects customer satisfaction and retention.

- It influences a company’s financial performance through cost efficiency.

- It defines the reliability and professionalism of a brand in a competitive market.

Even a single error in this chain — such as sending the wrong product or delaying a shipment — can trigger customer complaints, refunds, and negative reviews that are difficult to recover from.

Common Causes of Logistics Errors in Fulfillment

Mistakes in logistics don’t happen by accident. They are usually the result of flawed systems, outdated technology, or a lack of coordination among departments. Below are some of the most frequent causes.

1. Human Errors in Picking and Packing

Manual picking and packing are still common in many warehouses. When staff members handle multiple orders simultaneously, confusion and fatigue can lead to errors such as incorrect quantities, wrong items, or misplaced packages. Even small mix-ups can create big issues once products reach the wrong destination.

2. Poor Inventory Management

When inventory data is inaccurate or not updated in real-time, it can lead to overselling or stockouts. This not only causes delays but also frustrates customers who expected timely delivery. Businesses that rely on spreadsheets or disconnected systems often face this issue more frequently than those using automated warehouse management systems (WMS).

3. Lack of Communication Between Teams

Effective logistics requires coordination between sales, warehouse, and transportation teams. A lack of communication can result in orders being processed late, shipping instructions being ignored, or customer requests being missed entirely. Miscommunication is one of the most common but preventable causes of fulfillment failure.

4. Inefficient Logistics Partners

Sometimes, the problem lies outside the company. If third-party logistics (3PL) providers fail to handle goods properly, delays, damages, or incorrect deliveries can occur. Partnering with unreliable carriers can lead to repeated issues that damage your reputation.

5. Technical Glitches and System Downtime

Modern logistics relies heavily on technology. A system crash, software bug, or integration issue between platforms can delay order processing and cause duplication or loss of data. Companies without proper IT support or data backup systems are especially vulnerable.

The Consequences of Fulfillment Errors

1. Decline in Customer Trust

When customers receive the wrong product or experience long delays, their confidence in the brand diminishes. In e-commerce, where word-of-mouth and reviews matter, even one bad experience can discourage future purchases. Restoring trust takes far longer than losing it.

2. Increased Operational Costs

Order fulfillment errors often lead to expensive corrective actions such as product returns, replacements, and reshipments. Each of these adds to logistics costs, eats into profit margins, and consumes time that could be spent fulfilling new orders.

3. Higher Return and Refund Rates

Incorrect or damaged orders directly lead to product returns. Handling these returns requires additional manpower, packaging, and administrative work. Over time, a high return rate can signal inefficiency to both customers and investors.

4. Negative Impact on Brand Reputation

In today’s digital marketplace, customers often share negative experiences online. A few poor reviews related to fulfillment can quickly spread, affecting potential buyers and search rankings. A damaged reputation can take months or even years to repair.

5. Supply Chain Disruptions

Errors at the fulfillment stage can create a domino effect across the supply chain. For example, incorrect stock levels may trigger emergency reorders or delay shipments to other markets. These disruptions reduce overall efficiency and may cause shortages in key regions.

How to Prevent Order Fulfillment Mistakes

While no logistics process is completely error-proof, several strategies can help reduce mistakes and improve accuracy across operations.

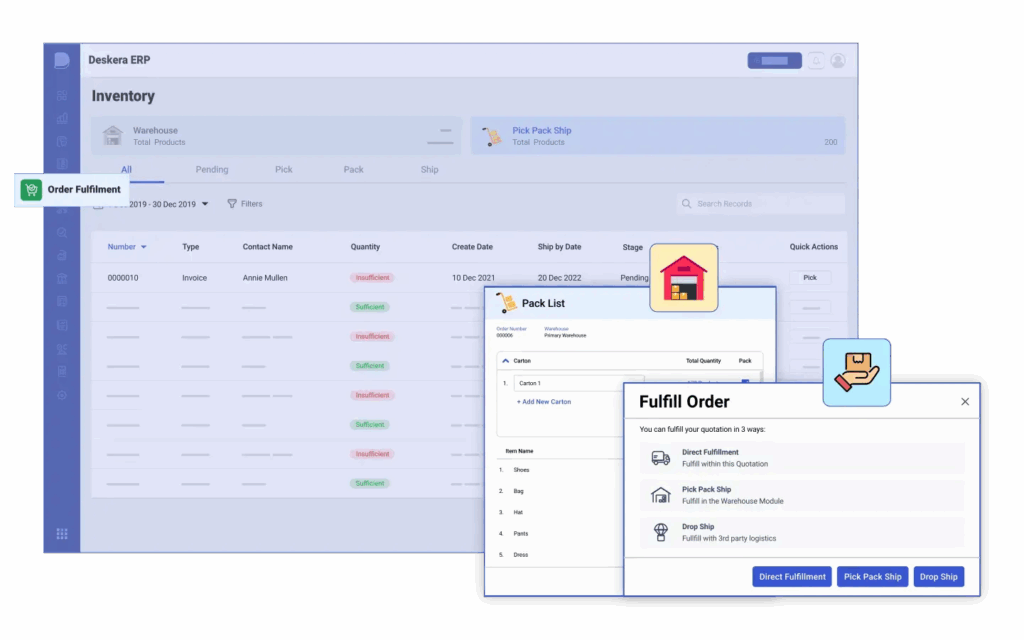

1. Implement Warehouse Management Systems (WMS)

A modern WMS automates inventory tracking, order picking, and packing verification. It minimizes human errors by providing real-time data and barcode scanning. These systems also generate performance reports, helping managers identify and fix weak points quickly.

2. Train Employees Effectively

Staff training is often underestimated in logistics. Teaching employees how to use systems properly, follow standard procedures, and double-check critical details reduces the chance of costly errors. Regular refresher sessions also keep teams aligned with best practices.

3. Optimize Communication Between Departments

Seamless communication is essential for smooth operations. Integrating your sales, warehouse, and shipping systems ensures that every order detail — from address to delivery method — is consistent and visible across all teams. Using collaboration tools or shared dashboards can improve real-time coordination.

4. Partner with Reliable Logistics Providers

Choosing a reputable 3PL or shipping partner can prevent many delivery-related issues. Evaluate partners based on their track record, delivery accuracy, and customer service response times. Long-term relationships with trusted logistics providers often yield better reliability.

5. Use Quality Control Checks

Establishing a final quality control checkpoint before shipping helps catch errors that may have slipped through earlier stages. This step might include verifying order details, scanning barcodes, or re-checking packing slips. Even a quick review can save time and money later.

6. Leverage Data Analytics and Automation

Using analytics tools allows companies to track performance trends such as order accuracy rates, return reasons, and delivery times. Automated alerts can notify staff when anomalies occur, helping businesses respond faster to potential problems.

The Role of Technology in Accurate Fulfillment

Technology continues to reshape logistics. From AI-driven demand forecasting to automated warehouse robots, digital innovation is reducing the margin for error in fulfillment. Systems powered by artificial intelligence can analyze patterns, predict inventory shortages, and suggest the fastest shipping routes. Real-time tracking tools also improve transparency for both businesses and customers.

PostalParcel, for example, integrates intelligent order tracking and fulfillment monitoring to help e-commerce businesses manage complex cross-border operations efficiently. By combining logistics data with automated workflows, it ensures higher accuracy and faster deliveries — key factors in maintaining customer trust and reducing costs.

Why Accuracy Defines Long-Term Success

Accurate order fulfillment is more than a logistics target; it is a business foundation. Every successful delivery strengthens the connection between brand and customer, while every error weakens it. Companies that invest in accuracy not only reduce costs but also create a better customer experience that leads to repeat business and positive referrals.

In the competitive landscape of global e-commerce, precision in logistics defines winners and losers. Businesses that treat fulfillment accuracy as a priority will always have a stronger advantage in speed, reliability, and reputation — the true pillars of long-term growth.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua