How to Optimize Cross-Border Fulfillment to Lower Shipping Costs

Cross-border fulfillment is one of the biggest challenges for DTC (Direct-to-Consumer) brands. Shipping across multiple countries quickly becomes expensive and complicated. Yet optimizing cross-border fulfillment is the key to lowering shipping costs while keeping customers happy. Brands that approach fulfillment strategically gain an edge in both pricing and delivery speed.

This guide explores practical steps, overlooked strategies, and technology-driven solutions to help DTC brands cut international shipping expenses without reducing service quality.

Understanding Cross-Border Fulfillment

Why It Matters for DTC Brands

Cross-border fulfillment involves more than just moving goods across borders. It also covers duties, local carriers, customs clearance, packaging, and returns. If done poorly, cross-border fulfillment can raise costs and lower customer trust. However, when optimized, it can turn into a competitive advantage.

Key Cost Drivers

- International shipping rates

- Customs duties and taxes

- Warehousing and storage fees

- Returns handling

Knowing where the money goes is the first step in optimizing fulfillment.

1. Consolidate Shipments for Lower Rates

The Problem with Small Shipments

Many DTC brands ship parcels individually from one origin country. This creates high per-unit costs and unpredictable delivery times.

The Power of Consolidation

Grouping shipments into bulk packages before sending them internationally lowers the cost per unit. Once the goods reach the destination country, they can be separated and delivered locally.

Advantages:

- Reduced freight charges

- Easier customs clearance for bulk entries

- Lower risk of lost packages

2. Use Regional Warehouses and Fulfillment Centers

Cutting Last-Mile Costs

Shipping directly from one central warehouse may be cheap for domestic orders but expensive for international deliveries. Regional warehouses reduce the distance to customers.

Examples of Benefits

- Europe: A U.S. brand can store goods in Germany or the Netherlands to serve the EU quickly.

- Asia-Pacific: Warehousing in Singapore or Hong Kong provides easy access to multiple markets.

Lower Shipping Costs

By storing inventory closer to customers, brands pay less for international shipping and speed up delivery times.

3. Optimize Carrier Selection

Avoiding Over-Reliance on One Carrier

Working with only one global carrier often results in fixed, higher costs. Each carrier has strong and weak routes.

Multi-Carrier Strategy

Brands should compare real-time rates across multiple carriers. For example, DHL might be cost-effective for Europe, while UPS could perform better for North America.

Tip: Use platforms that integrate multiple carriers and provide transparent rate comparisons.

4. Leverage Technology for Predictive ETAs

Why Predictive ETAs Matter

Customers often abandon purchases if delivery times are unclear. At the same time, inaccurate ETAs increase support costs.

How Technology Helps

Platforms with predictive ETAs analyze historical lane data, customs performance, and real-time conditions to provide accurate delivery windows.

Impact on Costs:

- Fewer “Where is my order?” inquiries

- Better carrier planning

- Higher customer satisfaction leads to repeat purchases

5. Simplify Customs and Duties

Common Mistakes

Many DTC brands fail to include customs and taxes upfront, causing delays and unexpected costs at delivery.

Solutions

- DDP (Delivered Duty Paid): Brands pay duties in advance, ensuring smooth delivery for customers.

- HS Code Accuracy: Correct product classification avoids overpaying taxes.

- Automated Customs Tools: Platforms can generate paperwork and reduce manual errors.

Why This Lowers Costs

Smooth customs clearance avoids penalties, storage fees, and returns caused by shipment rejections.

6. Improve Packaging Efficiency

How Packaging Affects Costs

Carriers often charge based on dimensional weight. Oversized packaging leads to higher charges even if the product is light.

Best Practices

- Use right-size packaging to reduce dimensional weight.

- Switch to lighter but durable materials.

- Standardize packaging sizes to fit carrier requirements.

Result: Smaller packaging lowers freight charges and improves warehouse efficiency.

7. Strengthen Return Logistics

The Overlooked Cost Driver

Returns can account for 20–30% of cross-border shipments in categories like fashion. If not managed properly, they eat into margins.

How to Optimize

- Set up regional return centers.

- Offer pre-printed return labels to avoid customer frustration.

- Track return reasons to identify product or sizing issues.

Cost Advantage: Lower handling fees, quicker resale of returned goods, and fewer disputes.

8. Use Data and Analytics for Smarter Decisions

Beyond Basic Tracking

Analytics can reveal patterns in delivery performance, peak-season delays, and cost fluctuations across carriers.

Examples of Insights

- Carrier A has higher costs but lower delays in Asia.

- Customs clearance times double during holidays in certain regions.

- Certain packaging sizes consistently trigger higher dimensional weight charges.

By acting on these insights, brands reduce costs while keeping reliability.

9. Consider Hybrid Fulfillment Models

Mixing Global and Local Strengths

Instead of relying only on international carriers or local couriers, hybrid models combine both.

Example:

- Bulk ship to a local hub.

- Hand over parcels to last-mile delivery partners.

Benefits

- Lower last-mile costs.

- Better customer experience through local carriers.

- Improved flexibility during peak seasons.

10. Negotiate Contracts with Carriers

Why Negotiation Works

Carriers compete aggressively for bulk business. DTC brands often miss the chance to negotiate because they assume their volumes are too small. In reality, even medium-sized brands can unlock better terms by approaching carriers strategically, especially when they demonstrate growth potential or consistent international lanes.

How to Approach

- Present combined volumes across regions.

- Use analytics to show consistent shipping lanes.

- Lock in discounts through yearly contracts.

- Explore tiered pricing that rewards higher volumes.

Result: Lower per-shipment rates, more predictable costs, and stronger long-term relationships with carriers that can support your expansion goals.

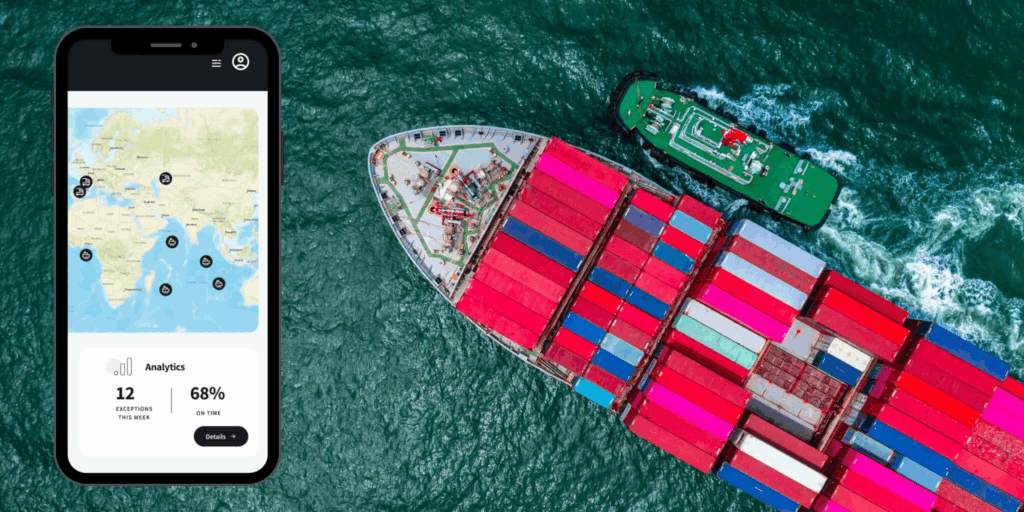

How PostalParcel Supports Cost Optimization

PostalParcel is built to help DTC brands lower cross-border fulfillment costs while keeping customer experience strong.

Features That Drive Savings

- Multi-carrier integration for real-time rate comparison.

- Predictive ETAs to improve delivery accuracy.

- Customs automation to cut delays.

- Regional return management to reduce losses.

- Analytics dashboards to uncover hidden costs.

- Branded tracking pages that reduce support costs and boost customer trust.

By combining these tools, PostalParcel enables brands to scale globally without being weighed down by high shipping expenses.

Conclusion

Optimizing cross-border fulfillment to lower shipping costs requires more than just comparing rates. DTC brands must look at consolidation, regional warehousing, carrier mix, predictive ETAs, customs accuracy, and packaging efficiency. Adding technology-driven insights and proactive returns management ensures cost savings while keeping customer satisfaction high.

With solutions like PostalParcel, brands can simplify cross-border logistics, cut hidden costs, and deliver smoother global experiences.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua