Schlüsseltechnologien für das Tracking in der Rückwärtslogistik

Umgekehrte Logistik Die Rückverfolgung ist zu einem entscheidenden Element moderner Lieferketten geworden. Sie konzentriert sich auf die Überwachung von Produkten auf ihrem Weg vom Kunden zum Einzelhändler oder Hersteller. Von Warenrücksendungen und Garantiereparaturen bis hin zum Recycling und der Wiederaufbereitung - die Rückwärtslogistikverfolgung bietet Unternehmen Transparenz und Kontrolle in Echtzeit. Unternehmen wie Postpaket vereinfachen diesen Prozess, indem sie Dienstleistungen anbieten, die es Marken ermöglichen, Rücksendungen effizient abzuwickeln und gleichzeitig die Kosten zu senken und die Kundenzufriedenheit zu verbessern.

Verstehen der Rückverfolgbarkeit von Logistik

Die Rückverfolgungslogistik ist ein System zur Überwachung von Produkten auf ihrem Weg durch die Rückgabe. Es stellt sicher, dass jeder Schritt aufgezeichnet wird, vom Zeitpunkt, an dem ein Kunde eine Rücksendung veranlasst, bis zu dem Zeitpunkt, an dem der Artikel repariert, recycelt oder wieder auf Lager genommen wird.

Warum es wichtig ist

- Bessere Kundenbetreuung: Die Kunden erhalten klare Informationen über den Status ihrer Rücksendung oder ihres Umtauschs.

- Niedrigere Betriebskosten: Rationalisierte Sammlung und Bearbeitung von Rücksendungen reduzieren die Kosten.

- Einhaltung der Nachhaltigkeit: Unternehmen können Recycling und Entsorgung nachverfolgen, um Umweltvorschriften einzuhalten.

Mit genauen Rückverfolgung der Logistikkönnen Unternehmen Muster bei Rücksendungen erkennen, den Bestand anpassen und die Betriebsplanung verbessern.

Schlüsselprozesse in der Rückwärtslogistik

- Rückkehr Initiierung: Die Kunden stellen online oder im Geschäft einen Rückgabeantrag.

- Produkt-Kollektion: Die Sendungen werden an bestimmten Stellen abgeholt oder abgegeben.

- Inspektion und Sortierung: Die Waren werden auf Schäden geprüft und für Reparatur, Wiederverkauf oder Recycling kategorisiert.

- Reparatur oder Instandsetzung: Für die Wiederverwendung geeignete Gegenstände werden repariert oder aufgearbeitet.

- Endgültige Disposition: Die Produkte werden entweder wieder aufgefüllt, recycelt oder sicher entsorgt.

Diese Schritte schaffen einen geschlossenen Kreislauf, der nicht nur Ressourcen spart, sondern auch das Vertrauen der Kunden stärkt.

Kerntechnologien für das Tracking in der umgekehrten Logistik

Internet der Dinge (IoT)

IoT-Sensoren spielen eine Schlüsselrolle bei der Überwachung von Sendungen in Echtzeit. Diese Sensoren bieten:

- Temperatur- und Feuchtigkeitsdaten zum Schutz empfindlicher Produkte.

- Standortverfolgung, um sicherzustellen, dass die Sendungen die richtige Einrichtung erreichen.

- Sofortige Warnmeldungen bei Verspätungen oder Schäden.

Das Internet der Dinge ermöglicht eine proaktive Entscheidungsfindung und verringert das Risiko von verlorenen oder beschädigten Waren. So können Sensoren die Teams sofort benachrichtigen, wenn eine Elektroniksendung hoher Luftfeuchtigkeit ausgesetzt ist, wodurch weitere Schäden verhindert und die Rücksendung beschleunigt wird.

RFID- und Barcode-Systeme

RFID-Etiketten und Barcodes automatisieren die Datenerfassung. Sie:

- Beschleunigen Sie den Scanvorgang in jeder Phase der Rückreise.

- Verringern Sie menschliche Fehler bei der Erfassung von Produktdaten.

- Bieten Sie schnelle Einblicke in Produktbedingungen und -standorte.

Durch die Bereitstellung einer zuverlässigen digitalen Aufzeichnung, RFID- und Barcode-Systeme den umgekehrten Warenfluss ebenso reibungslos zu gestalten wie die Vorwärtsverteilung.

Cloud-basierte Plattformen

Die Cloud-Technologie ermöglicht zentralisierte Plattformen für die Rückverfolgung der Logistik. Sie ermöglicht:

- Gemeinsame Nutzung von Daten in Echtzeit über mehrere Abteilungen hinweg.

- Einfache Integration in E-Commerce- und Lagerverwaltungssysteme.

- Skalierbare Lösungen, die mit den Geschäftsanforderungen wachsen.

Mit Cloud-basierte Systemekönnen Teams jederzeit auf dieselben Daten zugreifen, was die Koordination und Effizienz verbessert. Unternehmen können Cloud-Plattformen auch nutzen, um Status-Updates direkt mit Kunden zu teilen und so die Transparenz zu erhöhen.

Künstliche Intelligenz und Datenanalyse

KI und Analytik verbessern die Entscheidungsfindung. Diese Werkzeuge:

- Vorhersage von Renditetrends zur Unterstützung von Unternehmen bei der Bestandsplanung.

- Erkennung von Betrug oder abnormalen Rückgabemustern.

- Empfehlung von Prozessverbesserungen auf der Grundlage von Datenerkenntnissen.

Durch die Kombination von KI mit der Rückverfolgung der Logistik können Unternehmen Kosten senken und die Nachhaltigkeit verbessern. So kann die prädiktive Analytik beispielsweise Produkte mit hohem Rücklauf identifizieren und Unternehmen dabei helfen, das Produktdesign oder die Verpackung zu verbessern.

Mobile Anwendungen

Mobile Apps bieten Mitarbeitern und Kunden direkten Zugang zu Aktualisierungen der Sendungsverfolgung. Die Funktionen umfassen:

- Echtzeit-Benachrichtigungen über den Rückgabestatus.

- Einfach Scannen von Barcodes oder QR-Codes für die Bearbeitung von Rücksendungen.

- Sichere Kommunikation zwischen Logistikteams und Kunden.

Das sorgt für Transparenz und verbessert das Rückgabeerlebnis insgesamt. Kunden können ihre zurückgegebenen Artikel von ihrem Telefon aus verfolgen, ohne den Kundendienst anrufen zu müssen.

Blockchain für Sicherheit und Transparenz

Blockchain-Technologie fügt der Verfolgung der Rückwärtslogistik eine Ebene des Vertrauens hinzu:

- Erzeugt einen unveränderlichen Datensatz für jeden Rückgabeschritt.

- Erhöht die Sichtbarkeit für alle Beteiligten, einschließlich Kunden und Partner.

- Verringert Streitigkeiten durch einen fälschungssicheren Nachweis der Rückgabe.

Blockchain kann besonders in Branchen wertvoll sein, die mit hochwertigen Gütern handeln, bei denen der Nachweis der Echtheit und die sichere Handhabung von entscheidender Bedeutung sind.

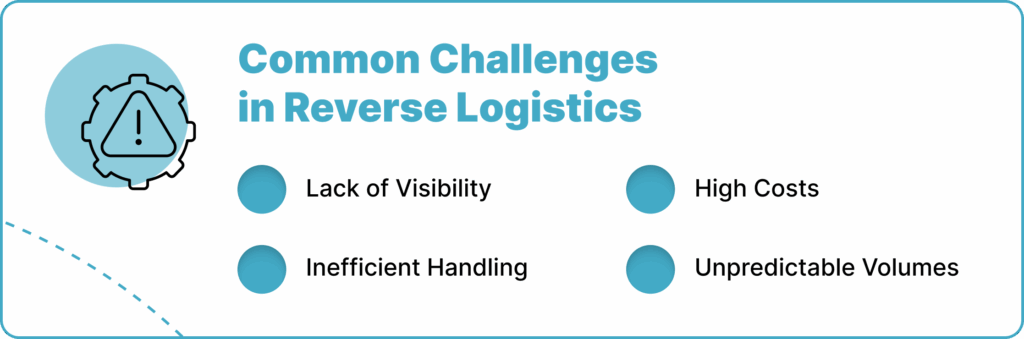

Herausforderungen bei der Rückverfolgung der Logistik

Die Technologie bringt zwar viele Vorteile mit sich, aber es gibt auch Herausforderungen:

- Datensicherheit: Der Schutz sensibler Kunden- und Produktdaten ist von entscheidender Bedeutung.

- Systemintegration: Die Verknüpfung neuer Tracking-Technologien mit älteren Systemen kann komplex sein.

- Kostenmanagement: Die Implementierung fortschrittlicher Tools erfordert Vorabinvestitionen.

Die Bewältigung dieser Probleme erfordert eine sorgfältige Planung und zuverlässige Partner wie Postpaketdie sich auf den effizienten weltweiten Versand und die Unterstützung der Rückwärtslogistik spezialisiert hat.

Branchenspezifische Herausforderungen

- Einzelhandel und E-Commerce: Ein hohes Rücklaufaufkommen in der Hochsaison kann die Kontrollsysteme belasten.

- Elektronik: Geräte können aufgrund von Batterien oder gefährlichen Komponenten eine besondere Handhabung erfordern.

- Mode und Bekleidung: Die Verwaltung umfangreicher Rücksendungen und Umtauschaktionen erfordert eine präzise Bestandsverfolgung.

Die Unternehmen müssen ihre Reverse-Logistics-Strategien an die spezifischen Anforderungen ihrer Branche anpassen.

Bewährte Praktiken für eine effektive Rückverfolgung der Logistik

- Wählen Sie den richtigen Technologie-Stack

Kombinieren Sie IoT, RFID und cloudbasierte Systeme für eine umfassende Nachverfolgung. - Regelmäßige Schulung des Personals

Vergewissern Sie sich, dass Ihre Mitarbeiter mit den Nachverfolgungsinstrumenten und dem korrekten Umgang mit zurückgegebenen Waren vertraut sind. - Integration in bestehende Systeme

Verknüpfen Sie Plattformen zur Rückverfolgung der Logistik mit Bestands- und Auftragsverwaltungssystemen für einen nahtlosen Datenfluss.

- Fokus auf Datengenauigkeit

Regelmäßige Überprüfung der Tracking-Daten, um die Zuverlässigkeit zu erhalten und Fehler zu vermeiden. - Mit Kunden kommunizieren

Sorgen Sie für klare und rechtzeitige Aktualisierungen, um Vertrauen aufzubauen und Supportanfragen zu reduzieren. - Analytik nutzen

Nutzen Sie KI-gestützte Erkenntnisse, um die Nachfrage zu prognostizieren, Betrug zu reduzieren und die Effizienz zu steigern. - Entwicklung einer nachhaltigen Strategie

Verfolgen Sie recycelte Materialien und legen Sie Wert auf umweltfreundliche Praktiken, um die Umweltziele zu erreichen.

Die Zukunft der Rückverfolgbarkeit in der Logistik

Mit den wachsenden Anforderungen des elektronischen Handels und der Nachhaltigkeit wird die Rückverfolgung der Logistik noch wichtiger werden. Aufstrebende Technologien wie Blockchain und KI-gesteuerte Automatisierung werden für zusätzliche Sicherheit, Vorhersagekraft und betriebliche Effizienz sorgen. Die Systeme der Zukunft werden:

- Präziseres Angebot Echtzeit-Verfolgung mit fortschrittlichen IoT-Sensoren.

- Bieten Sie tiefere Einblicke durch maschinelles Lernen, um Erträge vorherzusagen, bevor sie eintreten.

- Integration in Initiativen der Kreislaufwirtschaft zur Maximierung von Produktwiederverwendung und Recycling.

Unternehmen, die jetzt in diese Technologien investieren, werden sich einen starken Wettbewerbsvorteil verschaffen. Die Verfolgung von Rücksendungen ist nicht mehr nur eine Unterstützungsfunktion, sondern ein entscheidender Faktor für Kundenzufriedenheit und operative Exzellenz. Durch den Einsatz der richtigen Tools und die Zusammenarbeit mit vertrauenswürdigen Logistikpartnern können Unternehmen Rückläufer von einer Herausforderung in eine Wachstumschance verwandeln und eine widerstandsfähigere und kundenorientierte Lieferkette aufbauen.

Einblicke in die Industrie

Nachrichten über den Posteingang

Nulla turp dis cursus. Integer liberos euismod pretium faucibua