TMS vs. WMS: Hauptunterschiede und Integration in der Logistik

In der modernen Logistiklandschaft, TMS und WMS sind zu unverzichtbaren Instrumenten für die präzisere und effizientere Verwaltung der Lieferkette geworden. Beide Systeme unterstützen zwar die logistischen Abläufe, haben aber unterschiedliche Funktionen.Transport Management System konzentriert sich auf das Verkehrswesen, und Lagerverwaltungssystem zu den Lageraktivitäten.

Verstehen der Unterschiede zwischen TMS und WMSDie Art und Weise, wie sie integriert werden, ist entscheidend für Unternehmen, die ihre Prozesse rationalisieren, Kosten senken und sich auf dem Markt behaupten wollen.

Was ist ein TMS??

A Transport-Management-System (TMS) ist eine Software, die für die Verwaltung von Warenbewegungen von einem Ort zum anderen entwickelt wurde. Sie übernimmt alles von der Routenoptimierung und der Auswahl des Transportunternehmens bis hin zur Sendungsverfolgung und Frachtkontrolle.

Schlüsselfunktionen des TMS:

- Planung und Terminierung von Sendungen

- Tarifvergleich und Betreiberauswahl

- Routenoptimierung auf der Grundlage von Zeit, Kosten und Service

- Sendungsverfolgung in Echtzeit

- Frachtprüfung und Rechnungsabgleich

- Abwicklung von Rücksendungen und Rückwärtslogistik

Branchen, die TMS einsetzen: E-Commerce, Einzelhandel, 3PLs, Fertigung, globaler Vertrieb.

Was ist ein WMS??

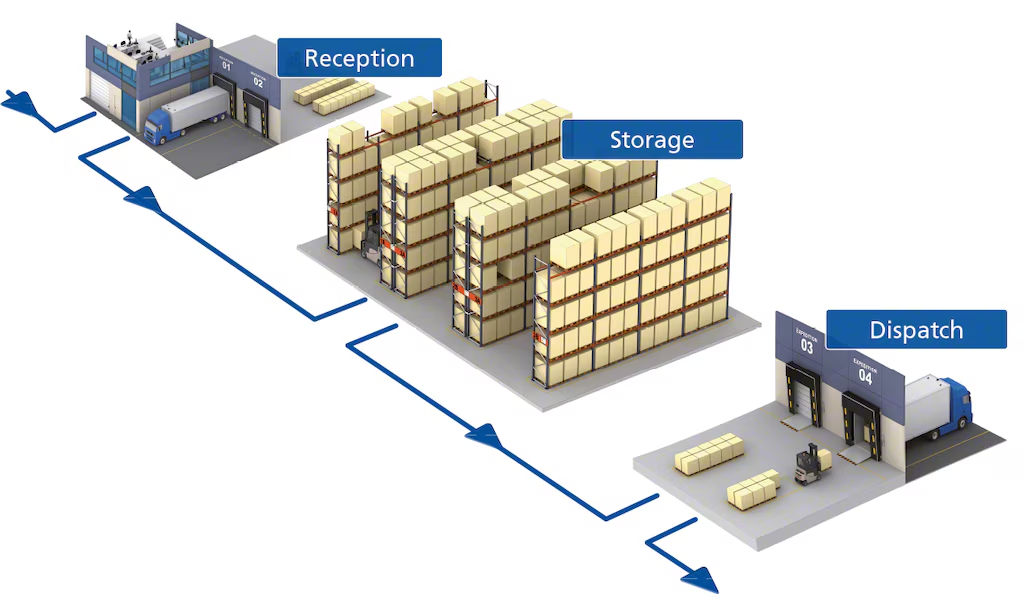

A Lagerverwaltungssystem (WMS) konzentriert sich auf die Verwaltung des Bestands, des Personals und der Abläufe in einem Lager. Es stellt sicher, dass die Waren mit maximaler Genauigkeit und Effizienz empfangen, gelagert, kommissioniert, verpackt und versandt werden.

Schlüsselfunktionen von WMS:

- Nachverfolgung des Lagerbestands und Slotting

- Barcode- und RFID-Scannen für Echtzeit-Updates

- Automatisierung von Kommissionierung und Verpackung

- Retourenmanagement und Wiederauffüllung der Lagerbestände

- Arbeitsmanagement und Optimierung der Arbeitsabläufe

Branchen, die WMS einsetzen: Großhandel, E-Commerce-Abwicklung, Logistikzentren, Einzelhandel, Pharmazeutika.

TMS vs. WMS: Kernunterschiede

MerkmalTMSWMS

Schwerpunktbereich Außerhalb des Lagers (Versand) Innerhalb des Lagers (Bestand)

Primäres Ziel Optimierung der Transportkosten und -zeit Maximierung der Lagereffizienz.

Hauptnutzer Logistikmanager, Transportteams, Lagerverwalter, Betriebsleiter

Verwendete Schlüsseldaten Frachtführertarife, Versandzonen, ETAs, SKU-Standorte, Kommissionierwege, Bestände.

Ausgabe Versandetiketten, Lieferverfolgung Kommissionierscheine, Bestandsberichte

Warum die Integration von TMS und WMS wichtig ist

TMS und WMS dienen zwar unterschiedlichen Zwecken, doch ihre Kombination erschließt leistungsstarke Lieferkettenfunktionen. Hier erfahren Sie, wie die Integration einen Mehrwert schafft:

1. End-to-End-Sichtbarkeit

Wenn TMS und WMS Echtzeitdaten austauschen, erhalten Logistikmanager einen ganzheitlichen Überblick über die Lieferkette - vom Auftragseingang bis zur Auslieferung auf der letzten Meile.

2. Schnellere Fertigstellung

Das WMS stößt den Kommissionier- und Verpackungsprozess an, während das TMS automatisch das Versandetikett erstellt, den Spediteur auswählt und die beste Route zuweist, was die Durchlaufzeiten erheblich verkürzt.

3. Reduzierte manuelle Fehler

Durch den automatisierten Datenfluss zwischen den Systemen werden doppelte Eingaben vermieden, Versandfehler reduziert und die Auftragsgenauigkeit verbessert.

4. Smarter Umgang mit Rücksendungen

Die Integration rationalisiert Rückgabeanfragen, verfolgt zurückgegebene Artikel im WMS und aktualisiert den Versandstatus über das TMS - eine Vereinfachung der Rückwärtslogistik.

Anwendungsfall aus der Praxis: E-Commerce-Logistik

Ein Online-Händler, der täglich mehr als 5.000 Pakete in den USA versendet, nutzt diese Möglichkeit:

- WMS um zwei Fulfillment-Zentren mit optimierten Slotting- und Pick-Pack-Workflows zu verwalten.

- TMS wählt automatisch Spediteure wie FedEx, UPS oder USPS auf der Grundlage von Region, Kosten und Zustellzeit aus.

- Die Integration beider Systeme ermöglicht die Aktualisierung des Auftragsstatus in Echtzeit, effiziente Rücksendungen und eine Reduzierung der Versandkosten durch 15%.

Die Wahl des richtigen TMS und WMS

Bei der Bewertung von Systemen sollten Sie Folgendes berücksichtigen:

KriterienTMS-ErwägungenWMS-Erwägungen

Skalierbarkeit: Kann es wachsende Sendungsmengen bewältigen? Unterstützt es den Betrieb mehrerer Lagerhäuser?

Integration API-Unterstützung mit ERP, WMS, OMS Synchronisierung mit TMS und E-Commerce-Plattformen

Benutzerfreundlichkeit Benutzerfreundliche Dashboards für Versandaufgaben Intuitive Schnittstellen für das Lagerpersonal.

Bereitstellung Cloud vs. On-Premise SaaS oder lokale Server-basiert

Beliebte TMS-Plattformen: Shipwell, EasyPost, MercuryGate

Beliebte WMS-Plattformen: NetSuite WMS, Logiwa, Manhattan Associates

Abschließende Überlegungen

TMS und WMS sind für eine erfolgreiche Logistik von entscheidender Bedeutung, aber sie kommen in unterschiedlichen Bereichen der Lieferkette zum Tragen. TMS kümmert sich um die Straßen und Spediteure, WMS um die Regale und Behälter. Zusammen bilden sie einen nahtlosen Logistikmotor.

Die Investition in beide Systeme - und deren effektive Integration - kann zu niedrigeren Kosten, schnellerem Versand, weniger Fehlern und zufriedeneren Kunden führen.

Möchten Sie Ihre Logistik modernisieren? Erwägen Sie die Integration von TMS und WMS, um eine durchgängige Effizienz zu erreichen.

Einblicke in die Industrie

Nachrichten über den Posteingang

Nulla turp dis cursus. Integer liberos euismod pretium faucibua

[...] Bedürfnisse: Muss das TMS mit ERP, WMS oder eCommerce verbunden werden [...]