Cómo optimizar el cumplimiento transfronterizo para reducir los gastos de envío

Cumplimiento transfronterizo es uno de los mayores retos para las marcas de venta directa al consumidor. Realizar envíos a varios países se convierte rápidamente en una tarea cara y complicada. Sin embargo, optimizar el cumplimiento transfronterizo es la clave para reducir los costes de envío y mantener contentos a los clientes. Las marcas que abordan el cumplimiento de forma estratégica obtienen una ventaja tanto en precios como en velocidad de entrega.

Esta guía explora pasos prácticos, estrategias olvidadas y soluciones basadas en la tecnología para ayudar a las marcas de DTC a recortar los gastos de envío internacional sin reducir la calidad del servicio.

Comprender el cumplimiento transfronterizo

Por qué es importante para las marcas DTC

El cumplimiento transfronterizo implica algo más que el simple traslado de mercancías a través de las fronteras. También incluye los aranceles, los transportistas locales, el despacho de aduanas, el embalaje y las devoluciones. Si se hace mal, el cumplimiento transfronterizo puede aumentar los costes y disminuir la confianza del cliente. Sin embargo, cuando se optimiza, puede convertirse en una ventaja competitiva.

Principales factores de coste

- Tarifas de envío internacional

- Derechos de aduana e impuestos

- Gastos de depósito y almacenamiento

- Gestión de devoluciones

Saber adónde va el dinero es el primer paso para optimizar el cumplimiento.

1. Consolidar los envíos para reducir las tarifas

El problema de los envíos pequeños

Muchos Marcas DTC enviar paquetes individualmente desde un país de origen. Esto genera elevados costes por unidad y plazos de entrega impredecibles.

El poder de la consolidación

Agrupar los envíos en paquetes a granel antes de enviarlos internacionalmente reduce el coste por unidad. Una vez que la mercancía llega al país de destino, puede separarse y entregarse localmente.

Ventajas:

- Gastos de transporte reducidos

- Despacho de aduanas más fácil para las entradas masivas

- Menor riesgo de pérdida de paquetes

2. Utilizar almacenes y centros de distribución regionales

Reducción de costes en el último tramo

El envío directo desde un almacén central puede ser barato para los pedidos nacionales, pero caro para las entregas internacionales. Los almacenes regionales reducen la distancia hasta los clientes.

Ejemplos de ventajas

- Europa: Una marca estadounidense puede almacenar mercancías en Alemania o los Países Bajos para servir rápidamente a la UE.

- Asia-Pacífico: El almacenamiento en Singapur o Hong Kong facilita el acceso a múltiples mercados.

Menores gastos de envío

Al almacenar el inventario más cerca de los clientes, las marcas pagan menos por los envíos internacionales y aceleran los plazos de entrega.

3. Optimizar la selección de operador

Evitar la dependencia excesiva de un solo transportista

Trabajar con un único transportista mundial suele traducirse en costes fijos más elevados. Cada transportista tiene rutas fuertes y débiles.

Estrategia multicarrier

Las marcas deben comparar en tiempo real tarifas entre varios transportistas. Por ejemplo, DHL podría ser rentable para Europa, mientras que UPS podría funcionar mejor para Norteamérica.

Consejo: Utilice plataformas que integren múltiples transportistas y ofrezcan comparaciones transparentes de tarifas.

4. Aprovechar la tecnología para predecir las horas de llegada previstas

Por qué son importantes los tiempos de llegada previstos

Los clientes suelen abandonar las compras si los plazos de entrega no están claros. Al mismo tiempo, los plazos de entrega imprecisos aumentan los costes de asistencia.

Cómo ayuda la tecnología

Las plataformas con ETA predictivos analizan los datos históricos de los carriles, el rendimiento de las aduanas y las condiciones en tiempo real para proporcionar ventanas de entrega precisas.

Impacto en los costes:

- Menos consultas del tipo "¿Dónde está mi pedido?

- Mejor planificación del transporte

- Más alto satisfacción del cliente lleva a repetir las compras

5. Simplificar aduanas y aranceles

Errores comunes

Muchas marcas de DTC no incluyen las aduanas y los impuestos por adelantado, lo que provoca retrasos y costes inesperados en la entrega.

Soluciones

- DDP (Entregado derechos pagados): Las marcas pagan los derechos por adelantado, lo que garantiza una entrega fluida a los clientes.

- Precisión del código SA: Una correcta clasificación de los productos evita pagar impuestos de más.

- Herramientas aduaneras automatizadas: Las plataformas pueden generar papeleo y reducir los errores manuales.

Por qué esto reduce los costes

Un despacho de aduanas sin problemas evita sanciones, gastos de almacenamiento y devoluciones causadas por rechazos de envíos.

6. Mejorar la eficiencia del envasado

Cómo afecta el envasado a los costes

Los transportistas suelen cobrar en función del peso dimensional. Un embalaje sobredimensionado conlleva cargos más elevados aunque el producto sea ligero.

Buenas prácticas

- Utilice envases del tamaño adecuado para reducir el peso dimensional.

- Cambia a materiales más ligeros pero duraderos.

- Estandarizar los tamaños de los envases para adaptarlos a los requisitos del transportista.

Resultado: Los envases más pequeños reducen los gastos de transporte y mejoran la eficiencia del almacén.

7. Reforzar la logística de retorno

El factor de coste ignorado

Las devoluciones pueden suponer el 20-30% de transfronterizo envíos en categorías como la moda. Si no se gestionan adecuadamente, se comen los márgenes.

Cómo optimizar

- Crear centros regionales de retorno.

- Ofrezca etiquetas de devolución preimpresas para evitar la frustración del cliente.

- Haga un seguimiento de los motivos de las devoluciones para identificar problemas con el producto o el tallaje.

Ventaja en costes: Menores gastos de tramitación, reventa más rápida de los productos devueltos y menos litigios.

8. Utilizar datos y análisis para tomar decisiones más inteligentes

Más allá del seguimiento básico

Los análisis pueden revelar patrones en el rendimiento de las entregas, retrasos en temporada alta y fluctuaciones de costes entre transportistas.

Ejemplos de ideas

- El transportista A tiene mayores costes pero menores retrasos en Asia.

- Los plazos de despacho de aduanas se duplican durante las vacaciones en algunas regiones.

- Determinados tamaños de envases generan sistemáticamente recargos por peso dimensional más elevados.

Al actuar sobre la base de estos conocimientos, las marcas reducen costes al tiempo que mantienen la fiabilidad.

9. Considerar modelos híbridos de cumplimiento

Combinación de fuerzas globales y locales

En lugar de confiar únicamente en internacional Los modelos híbridos combinan ambos.

Ejemplo:

- Envío a granel a un centro local.

- Entregar los paquetes a los socios de reparto de última milla.

Beneficios

- Reducción de los costes de última milla.

- Mejor experiencia del cliente gracias a los transportistas locales.

- Mayor flexibilidad durante las temporadas altas.

10. Negociar contratos con los transportistas

Por qué funciona la negociación

Los transportistas compiten agresivamente por el negocio a granel. Las marcas de DTC a menudo pierden la oportunidad de negociar porque asumen que sus volúmenes son demasiado pequeños. En realidad, incluso las marcas medianas pueden conseguir mejores condiciones si se dirigen estratégicamente a los transportistas, especialmente cuando demuestran potencial de crecimiento o rutas internacionales constantes.

Cómo abordar

- Presente los volúmenes combinados de todas las regiones.

- Utilice la analítica para mostrar rutas de envío coherentes.

- Bloquee los descuentos mediante contratos anuales.

- Explore precios escalonados que recompensen los mayores volúmenes.

Resultado: Tarifas por envío más bajas, costes más predecibles y relaciones a largo plazo más sólidas con transportistas que pueden respaldar sus objetivos de expansión.

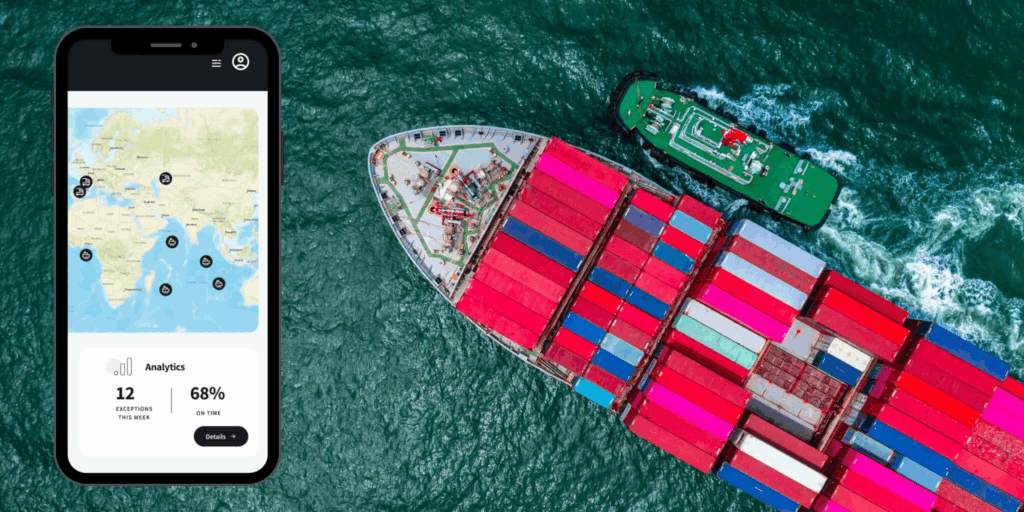

Cómo PostalParcel contribuye a la optimización de costes

PostalParcel está diseñado para ayudar a las marcas de venta directa a reducir los costes de distribución transfronteriza, manteniendo al mismo tiempo la experiencia del cliente.

Características que impulsan el ahorro

- Integración multiportadora para comparar tarifas en tiempo real.

- Predicción del tiempo estimado de llegada para mejorar la precisión de la entrega.

- Automatización aduanera para reducir los retrasos.

- Gestión regional de las devoluciones para reducir las pérdidas.

- Cuadros de mando analíticos para descubrir costes ocultos.

- Páginas de seguimiento de marca que reducen los costes de asistencia y aumentan la confianza de los clientes.

Al combinar estas herramientas, PostalParcel permite a las marcas escalar globalmente sin verse lastradas por los elevados gastos de envío.

Conclusión

Optimizar el cumplimiento transfronterizo para reducir los costes de envío requiere algo más que comparar tarifas. Las marcas de DTC deben tener en cuenta la consolidación, el almacenamiento regional, la combinación de transportistas, los tiempos de llegada previstos, la precisión aduanera y la eficiencia del embalaje. La incorporación de conocimientos tecnológicos y la gestión proactiva de las devoluciones garantizan el ahorro de costes y mantienen alta la satisfacción del cliente.

Con soluciones como PostalParcel, las marcas pueden simplificar logística transfronterizareducir costes ocultos y ofrecer experiencias globales más fluidas.

Perspectivas del sector

noticias vía inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua