Forward vs Reverse Logistics Tracking: What 90% Managers Get Wrong

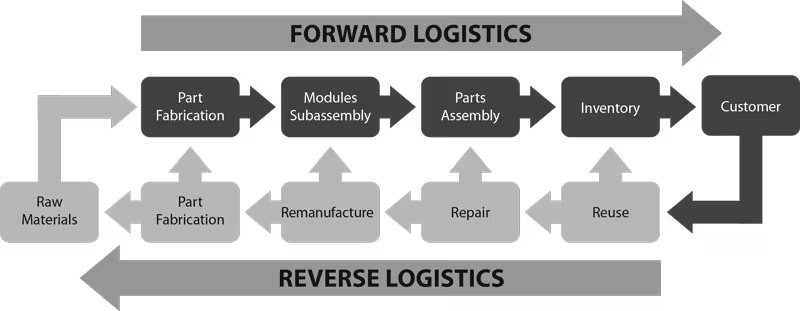

Most supply chain managers believe they fully understand logistics, yet 90% overlook the hidden complexity of Reverse Logistics Tracking. Forward logistics handles products moving from manufacturer to customer; reverse logistics manages the flow in the opposite direction—returns, recycling, repairs, or refurbishing.

The gap lies in how these two systems are tracked, optimized, and analyzed. Reverse Logistics Tracking is no longer a post-sale afterthought—it’s a data-driven discipline that can save millions and build brand loyalty.

This guide explains what managers often get wrong, why reverse tracking is essential, and how technology can help close the performance gap.

Understanding the Real Difference Between Forward and Reverse Logistics

Forward logistics tracking involves monitoring products from the point of origin to the customer. It focuses on:

- Production planning

- Inventory management

- Shipment tracking

- Last-mile delivery visibility

The goal is speed, efficiency, and customer satisfaction. Metrics such as on-time delivery, cost per shipment, and order accuracy are the primary focus during this phase.

Despite its efficiency, forward logistics ends at delivery. Once a product is sold, many systems stop tracking. That’s where the problem starts.

Reverse Logistics Tracking monitors products returning from customers back to warehouses, suppliers, or recyclers. This includes:

- Returns and refunds

- Product repairs and refurbishments

- Recycling and waste management

- Warranty replacements

Unlike forward logistics, it deals with uncertainty—unplanned returns, varying product conditions, and complex routing.

Why Reverse Logistics Tracking Is Often Mismanaged

- Data fragmentation. Many businesses still manage returns using spreadsheets or isolated tools. Each department maintains separate records, resulting in data gaps and confusion. Without centralized Reverse Logistics Tracking, communication breaks down, and delays accumulate. A unified tracking system eliminates duplication, keeping all return data accurate and visible.

- Lack of visibility. When reverse processes aren’t tracked in real time, returned products can vanish in transit or sit idle for weeks. This slows refunds, repairs, and restocking. Reverse Logistics Tracking provides complete visibility through barcode scans and automated updates, allowing every item to be traced from origin to resolution.

- Underestimation of cost. Untracked returns can quietly consume 4–6% of logistics expenses. Each movement—pickup, inspection, and repackaging—adds cost. Reverse Logistics Tracking identifies where money leaks occur and helps cut unnecessary transportation and storage costs, turning returns into recoverable value.

However, with proper Reverse Logistics Tracking, companies can gain:

- Real-time visibility of returned products

- Process automation integrated with inventory and CRM

- Higher customer retention due to faster refunds or exchanges

- Sustainability benefits through recycling and waste reduction

Key Differences Between Forward and Reverse Logistics Tracking

| Aspect | Forward Logistics | Reverse Logistics |

|---|---|---|

| Direction | Manufacturer → Customer | Customer → Manufacturer |

| Predictability | Highly planned | Often unpredictable |

| Data Systems | Centralized ERP / WMS | Fragmented or manual |

| Goal | Fast delivery | Efficient recovery |

| Customer Impact | Pre-sale experience | Post-sale satisfaction |

| Sustainability Role | Limited | Crucial for circular economy |

Forward logistics is about pushing goods out. Reverse Logistics Tracking is about bringing value back in—through reuse, repair, or recycling.

Why Managers Get Reverse Logistics Tracking Wrong

They See It as a Cost Center

Most managers view reverse logistics as purely an expense, rather than a profit opportunity. Yet with proper tracking, refurbished or resold products can recover up to 60% of their original value.

They Lack Centralized Data

Without unified tracking, reverse logistics becomes a black hole of missing information—where items vanish in transit or stay in storage unrecorded.

They Ignore Customer Experience

Customers judge a brand by how easily they can return or replace a product. Poor tracking leads to delays, lost packages, and frustrated buyers.

They Don’t Use Metrics

Forward logistics thrives on KPIs. Reverse logistics rarely gets the same treatment. Managers should monitor:

- Return cycle time

- Percentage of recoverable value

- Cost per return

- Environmental impact per unit

They Underinvest in Technology

Many companies still manage returns manually via email or spreadsheets. In contrast, advanced Reverse Logistics Tracking systems use AI, IoT, and barcode integration to automate visibility and data capture.

How to Build a Smarter Reverse Logistics Tracking System

Step 1 – Map Your Reverse Flow

Document every return touchpoint—from customer request to warehouse intake. Identify where delays or blind spots occur.

Step 2 – Integrate Technology

Adopt unified platforms that connect reverse logistics with:

- ERP systems (to update stock)

- CRM tools (for customer communication)

- IoT sensors (for condition monitoring)

Step 3 – Automate Data Capture

Use barcode or QR scanning to log returns instantly. AI-driven analytics can predict return causes, helping you reduce future rates.

Step 4 – Prioritize Real-Time Visibility

Deploy dashboards that show the location, status, and condition of all returned goods. This transforms guesswork into actionable insight.

Step 5 – Measure and Optimize

Review key metrics monthly:

- Time to process a return

- Recovery rate of returned items

- Transportation costs saved through optimized routing

The Role of Reverse Logistics Tracking in Sustainability

Reverse logistics is essential to the circular economy. By tracking product returns and recycling routes, businesses reduce landfill waste and maximize reuse.

Environmental and Brand Benefits:

- Lower CO₂ emissions through optimized backhauls

- Improved ESG scores and compliance

- Enhanced customer perception of corporate responsibility

A company that implemented reverse tracking across 3,000 locations cut waste by 28% and logistics costs by 18% within a year—proof that sustainability and profitability can coexist.

How Forward and Reverse Tracking Work Together

A truly efficient supply chain doesn’t end at delivery. Integrating Reverse Logistics Tracking with forward tracking ensures every item’s lifecycle is traceable—from production to reuse.

Benefits of a Unified System:

- End-to-end visibility across the entire product lifecycle

- Better inventory accuracy

- Reduced excess manufacturing through the reuse of returned stock reuse

- More intelligent decision-making via unified analytics

By 2026, over 70% of logistics companies are expected to adopt integrated reverse tracking systems. AI and automation will shift returns management from a reactive to a predictive approach.

Standard Tool for Reverse Logistics Tracking

Recommended Solution: Postalparcel

Postalparcel is an all-in-one solution designed for businesses aiming to simplify and optimize their reverse logistics operations. It provides real-time tracking, intelligent routing, and end-to-end visibility for all return and exchange activities.

With Postalparcel, companies can:

- Monitor every return in real time, from customer drop-off to warehouse arrival.

- Automate routing to the nearest or most cost-efficient return center.

- Reduce handling delays through smart shipment assignment.

- Improve customer satisfaction with transparent return updates.

- Gain actionable insights through detailed analytics dashboards.

Core Features

- Cloud-based dashboard – Accessible from anywhere, offering real-time performance metrics.

- API integration – Seamlessly connects with ERP, CRM, and e-commerce systems for unified tracking.

- Real-time data visualization – Instantly displays return statuses, transit times, and performance KPIs.

- Multi-channel return support – Manages returns from web, retail, and cross-border orders on one platform.

Postalparcel empowers companies to streamline Reverse Logistics Tracking, cut unnecessary costs, and deliver a faster, more transparent post-sale experience.

Final Thoughts — Turning Mistakes into Measurable Wins

Reverse Logistics Tracking is no longer optional. The post-sale experience now defines customer loyalty, operational cost, and sustainability metrics. Forward logistics might win the sale, but reverse logistics keeps the customer.

Savvy managers no longer see it as an afterthought—they treat it as a competitive advantage.

Learn more about reverse logistics solutions at Postalparcel.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua