Optimiser les opérations d'entreposage : Améliorer l'efficacité grâce à l'agencement, l'automatisation et la gestion intelligente des stocks

I. Optimisation de l'agencement des entrepôts : Conception de l'espace et des processus

Aperçu général

Entrepôt sont essentielles à la logistique moderne, car elles sont au cœur de l'activité de l'entreprise. gestion de la chaîne d'approvisionnement. La gestion efficace des fonctions d'un entrepôt fait partie intégrante du succès de toute opération logistique, car elle a un impact direct sur les niveaux de stock, la vitesse d'exécution des commandes et la satisfaction des clients. Cependant, les opérations d'entreposage sont confrontées à des défis croissants, tels que la pression des coûts, les goulets d'étranglement en matière d'efficacité et une pénurie croissante de main-d'œuvre. Ces défis exigent des solutions innovantes pour optimiser les performances des entrepôts.

Objectifs d'optimisation

L'objectif premier de l'optimisation des opérations d'entreposage est de rationaliser les processus, de réduire les déchets et d'améliorer l'efficacité globale. Il s'agit de minimiser les pertes de temps, d'espace et de ressources, d'améliorer la productivité et de renforcer la réactivité de la chaîne d'approvisionnement face aux fluctuations de la demande.

Aperçu de l'article

Cet article explore les principales stratégies d'optimisation des opérations d'entreposage, notamment l'optimisation de l'agencement, la technologie d'automatisation et les systèmes intelligents de gestion des stocks. Nous montrerons comment ces approches peuvent être mises en œuvre dans des scénarios réels à l'aide d'études de cas et d'exemples pratiques.

II. Optimisation de l'agencement des entrepôts : Conception de l'espace et des processus

Planification de la zone de l'entrepôt scientifique

L'aménagement d'un entrepôt bien planifié est essentiel pour assurer le bon déroulement des opérations. L'entrepôt doit être divisé en zones fonctionnelles, telles que les zones de réception, de stockage, de préparation des commandes et d'expédition, afin de garantir l'organisation et l'efficacité du flux de travail. Un zonage approprié minimise la congestion et contribue à améliorer la rapidité des opérations.

- Zones fonctionnelles: La création de zones distinctes pour la réception, le stockage, la préparation des commandes et l'expédition permet à chaque zone de fonctionner de manière optimale sans interférence avec d'autres opérations.

Stratégie de stockage basée sur les UGS

Les différents types de produits (UGS) requièrent des stratégies de stockage différentes. La mise en œuvre de méthodes de classification des UGS telles que la méthode ABC (classification des produits en fonction de leur taux de rotation) permet un placement stratégique des produits dans l'entrepôt. Par exemple, les produits à forte demande (articles A) doivent être stockés plus près de la zone de préparation des commandes, tandis que les produits à faible rotation (articles C) peuvent être stockés plus loin.

- Étude de cas: Une entreprise de logistique a optimisé l'emplacement de ses UGS, réduisant le temps de prélèvement de 30% grâce à un zonage stratégique et à la classification des UGS.

Principes de conception des flux

L'optimisation des flux de matériaux dans l'entrepôt est essentielle pour minimiser les inefficacités. La conception de flux rationalisés, tels que les agencements en U ou en ligne droite, permet de réduire les mouvements inutiles. L'optimisation des chemins de préparation des commandes permet également d'accélérer l'exécution des commandes.

Utilisation de l'espace vertical

Il est essentiel de maximiser le stockage vertical pour tirer le meilleur parti de l'espace disponible dans l'entrepôt. L'utilisation de rayonnages plus hauts et de systèmes automatisés, tels que les systèmes de stockage et de récupération automatisés (AS/RS), permet d'accroître la capacité de stockage sans augmenter l'empreinte physique.

III. Applications des technologies d'automatisation

Équipements et outils automatisés

Les technologies d'automatisation transforment de plus en plus les opérations d'entreposage. Les véhicules à guidage automatique (AGV) et les robots mobiles autonomes (AMR) jouent un rôle crucial dans le déplacement des marchandises au sein de l'entrepôt, en réduisant le travail humain et en augmentant l'efficacité. Un exemple clé est Acquisition de Kiva Robotics par Amazon en 2012. L'entreprise a déployé des milliers d'AGV, révolutionnant ainsi les opérations de son entrepôt. Ces robots transportent automatiquement les étagères vers les postes de travail, ce qui permet aux employés de se concentrer uniquement sur la préparation des commandes à un endroit fixe.

- Systèmes de tri automatisés: L'intégration de systèmes tels que les machines de dimensionnement, de pesage et de scannage (DWS) permet d'accélérer le processus de tri, de garantir la précision et de réduire les erreurs manuelles.

Systèmes de stockage automatisés

Les systèmes de stockage avancés, tels que les chariots élévateurs sans conducteur et les systèmes de rayonnages automatisés à haute densité, améliorent considérablement l'utilisation de l'espace et l'efficacité opérationnelle. Ces systèmes permettent une manipulation plus rapide des stocks, réduisant ainsi les temps de préparation des commandes et les coûts opérationnels.

- Analyse des avantages: Une étude a montré que les entrepôts utilisant des systèmes de stockage automatisés à haute densité ont enregistré une réduction de 25% des coûts de main-d'œuvre et une augmentation de 15% de la capacité de stockage.

Technologies de fonctionnement collaboratif

Dispositifs IoT sont désormais utilisés pour surveiller les opérations de l'entrepôt en temps réel. Ces dispositifs peuvent suivre les niveaux de stock, l'état des équipements et les performances des systèmes, ce qui permet aux responsables d'entrepôts de procéder à des ajustements en temps voulu.

Automatisation et collaboration humaine

Le modèle hybride d'automatisation et de collaboration humaine, tel que les systèmes "Goods-to-Person" (G2P), permet de bénéficier des avantages des deux technologies. Les travailleurs humains sont intégrés aux systèmes robotiques afin d'obtenir une plus grande efficacité.

Coût et retour sur investissement (ROI)

Si l'investissement initial dans l'automatisation peut être élevé, les bénéfices à long terme l'emportent souvent sur les coûts. L'augmentation de la productivité, la réduction des coûts de main-d'œuvre et la diminution du nombre d'erreurs se traduisent par un retour sur investissement évident au fil du temps.

IV. Systèmes intelligents de gestion des stocks

Contrôle des stocks en temps réel basé sur des données

Dans les entrepôts modernes, il est essentiel de disposer d'un système robuste de gestion des stocks. Les technologies RFID et de codes à barres permettent un suivi précis des niveaux de stock, des mouvements de produits et de leur emplacement dans l'entrepôt. Cette visibilité en temps réel est essentielle pour optimiser les niveaux de stock et minimiser les erreurs.

- Alertes dynamiques sur les stocks: La mise en œuvre de modèles de juste-à-temps (JIT) et de stocks de sécurité garantit que les niveaux de stocks sont optimaux, réduisant ainsi le surstockage et les ruptures de stock.

Intégration et visualisation de logiciels

Un système de gestion d'entrepôt (WMS) intégré à un système de planification des ressources de l'entreprise (ERP) fournit un flux de données transparent à travers les opérations, permettant une meilleure prise de décision. Les outils d'analyse de données alimentés par des algorithmes d'IA peuvent prévoir les fluctuations de la demande, aidant ainsi les entreprises à planifier plus efficacement.

- Étude de cas: Une entreprise de vente au détail a utilisé un système d'inventaire intelligent pour réduire les coûts d'inventaire de 20% en mettant en œuvre le suivi en temps réel et l'analyse prédictive.

Réduire les déchets d'inventaire

Des techniques telles que le FIFO (First In, First Out) et la gestion efficace des stocks à rotation lente permettent de minimiser le gaspillage et d'améliorer la rotation des stocks. La mise en œuvre de systèmes de réapprovisionnement intelligents permet également d'éviter les surstocks et les sous-stocks.

V. Formation des employés et amélioration continue

Amélioration des compétences des employés

Avec l'avènement de l'automatisation, les compétences des employés doivent être continuellement mises à jour. La formation des employés au fonctionnement des équipements automatisés et la normalisation des processus garantissent qu'ils peuvent s'adapter aux nouvelles technologies et procédures.

Gestion des performances et incitations

Définition claire Indicateurs clés de performance (KPI), tels que la vitesse et la précision de traitement des commandes, permet de suivre les performances et de motiver les employés pour qu'ils atteignent leurs objectifs. Récompenser les employés les plus performants par des primes favorise une culture de l'excellence et de l'amélioration continue.

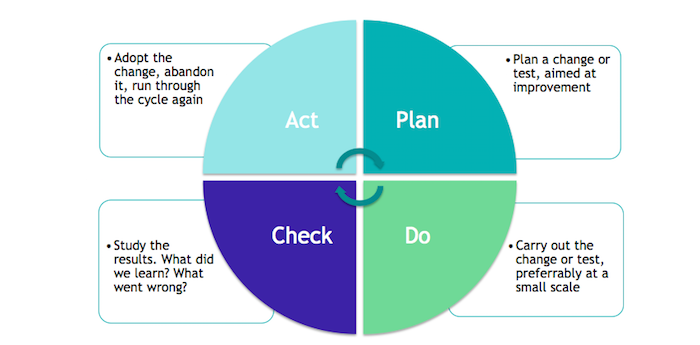

Mécanisme d'optimisation continue

L'utilisation du cycle PDCA (Plan-Do-Check-Act) permet aux entreprises d'évaluer régulièrement leurs processus et d'y apporter des améliorations. Des audits périodiques des processus permettent de s'assurer que les flux de travail restent optimisés et que toute inefficacité est corrigée.

VI. Défis et tendances futures

Défis communs

Malgré les avantages évidents de l'optimisation, plusieurs défis subsistent. Il s'agit notamment de la résistance à l'adoption de la technologie, de l'adaptation des employés aux nouveaux outils et des coûts initiaux élevés associés à l'automatisation.

Orientations futures

L'avenir de la gestion des entrepôts réside dans l'intégration de l'intelligence artificielle (IA) pour l'analyse prédictive et le développement d'"entrepôts verts" qui intègrent des pratiques durables telles que des équipements économes en énergie et des emballages respectueux de l'environnement.

- L'IA dans l'analyse prédictive: L'IA peut analyser de grandes quantités de données pour prédire les fluctuations de la demande, ce qui permet de s'assurer que les entrepôts sont stockés de manière appropriée sans surstockage.

- Pratiques durables: Le passage à des entrepôts verts permettra de réaliser des économies d'énergie, de réduire l'impact sur l'environnement et de rendre la chaîne d'approvisionnement plus durable.

Conclusion

L'optimisation des entrepôts n'est pas seulement une tendance, c'est un élément essentiel de la gestion moderne de la chaîne d'approvisionnement. En mettant en œuvre des conceptions stratégiques d'aménagement d'entrepôt, en tirant parti de la technologie d'automatisation et en utilisant des systèmes intelligents de gestion des stocks, les entreprises peuvent considérablement accroître leur efficacité opérationnelle, réduire leurs coûts et améliorer la réactivité de leur chaîne d'approvisionnement. Au fur et à mesure de l'évolution du secteur, la clé du succès à long terme en matière de gestion d'entrepôt est de rester à la pointe des technologies et de procéder à des améliorations continues.Introduction

Aperçu de l'industrie

nouvelles via la boîte de réception

Nulla turp dis cursus. Integer liberos euismod pretium faucibua