Meilleures pratiques pour la mise en œuvre de la logistique inverse dans les chaînes d'approvisionnement mondiales

Logistique inverse en gestion de la chaîne d'approvisionnement est devenu un élément essentiel du commerce mondial moderne. Avec l'augmentation des ventes en ligne et des attentes des clients, le traitement efficace des retours est désormais aussi important que la livraison des produits dans les délais impartis. Les entreprises qui ne parviennent pas à gérer ce processus perdent de l'argent, du temps et la confiance de leurs clients. En revanche, les entreprises qui maîtrisent la logistique inverse peuvent transformer les défis en opportunités. Postalparcel, l'un des principaux fournisseurs de services logistiques, a pu constater de visu qu'un traitement adéquat des retours peut améliorer la durabilité, réduire les déchets et renforcer la fidélité à la marque.

Comprendre La logistique inverse dans la gestion de la chaîne d'approvisionnement

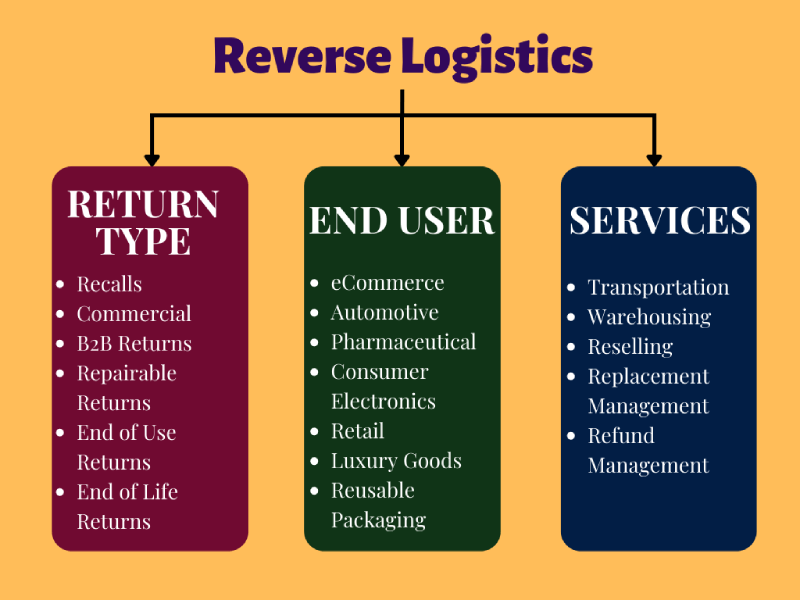

La logistique inverse consiste à gérer le mouvement des marchandises des consommateurs vers les vendeurs, les fabricants ou les recycleurs. Elle couvre les retours de produits, les réparations, les remises à neuf, le recyclage et l'élimination en toute sécurité. Ce processus garantit que chaque article, qu'il soit endommagé, indésirable ou en fin de vie, trouve sa destination.

Dans le cadre du commerce mondial, la logistique inverse devient plus complexe. Les produits peuvent traverser plusieurs pays, ce qui nécessite le respect des lois, des taxes et des normes environnementales locales. La gestion correcte de ces étapes garantit à la fois la maîtrise des coûts et la satisfaction du client.

Les principaux éléments sont les suivants

- Retours et échanges de clients.

- Inspection et contrôle de la qualité.

- Remise à neuf ou reconditionnement.

- Recyclage et gestion des déchets.

- Coordination du retour au fournisseur.

Un plan de logistique inverse bien structuré aide les entreprises à gérer ces étapes de manière transparente, en veillant à ce que chaque article soit pris en compte et traité de manière responsable.

L'importance de la logistique inverse dans les chaînes d'approvisionnement mondiales

Dans le cadre de la gestion de la chaîne d'approvisionnement, la logistique inversée ne concerne pas seulement les aspects suivants la gestion des rendements-Il s'agit de protéger la réputation de la marque et de maintenir l'efficacité de l'entreprise.

Voici pourquoi c'est important :

- Recouvrement des coûts : Les entreprises peuvent récupérer la valeur des biens remis à neuf ou revendus.

- Satisfaction des clients : La facilité des retours augmente la confiance des consommateurs.

- Durabilité : Le recyclage et la réutilisation des matériaux soutiennent les objectifs environnementaux.

- Conformité : L'élimination correcte des déchets répond aux normes environnementales internationales.

Les consommateurs modernes s'intéressent à ce qui se passe après le retour d'un produit. Une marque qui traite les retours de manière responsable gagne le respect et la confiance à long terme.

Construire un cadre solide pour la logistique inverse

1. Des politiques de retour claires

La transparence est essentielle. Les clients doivent savoir comment retourner les articles sans confusion. Affichez les politiques de retour sur les pages des produits, dans les sections de paiement et dans les courriels de confirmation.

Bonnes pratiques :

- Veillez à ce que les étapes du retour soient simples et faciles à suivre.

- Offrir des informations de contact claires pour l'assistance à la clientèle.

- Communiquer les délais de remboursement et d'échange.

Une procédure claire permet de réduire les litiges et d'améliorer l'expérience des clients.

2. Collecte efficace des retours

La centralisation des retours dans des centres régionaux clés améliore le contrôle. Au lieu de renvoyer les articles à un seul site mondial, les entreprises peuvent traiter les retours au niveau régional.

Les avantages comprennent

- Réduction des coûts de transport.

- Tri et évaluation plus rapides.

- Faciliter le recyclage ou la revente au niveau local.

Colis postal fournit de telles solutions régionales de traitement des retours, permettant aux marques de gérer les retours globaux en douceur grâce à des centres logistiques intégrés.

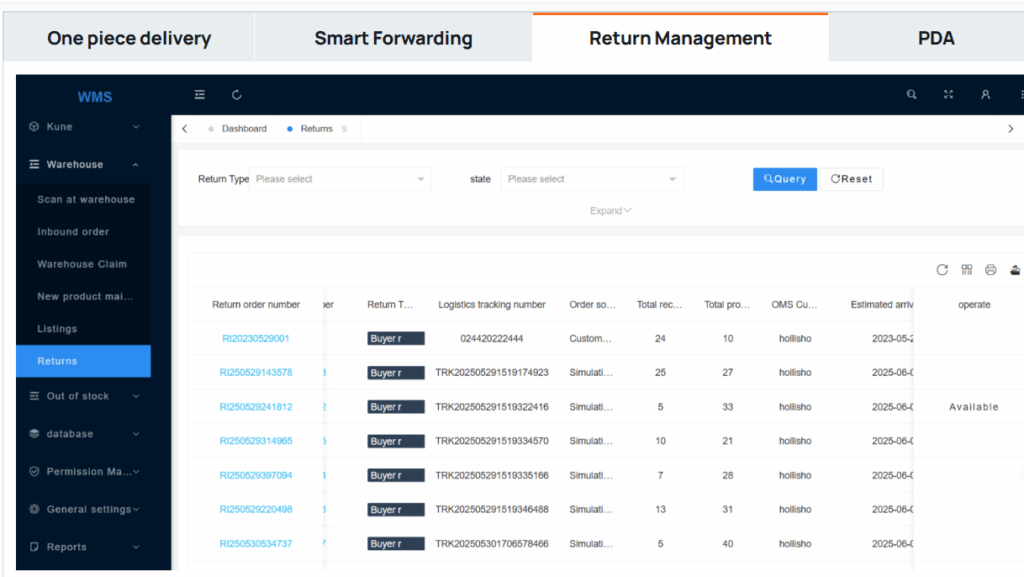

3. Intégration intelligente des technologies

La technologie améliore la visibilité à chaque étape de la logistique inverse. Les systèmes de suivi en temps réel, les codes-barres et les tableaux de bord basés sur le cloud aident les entreprises à contrôler les produits au fur et à mesure de leur retour.

Avantages :

- Meilleure visibilité des marchandises en transit.

- Réduction des erreurs dans la documentation.

- Résolution plus rapide des demandes de remboursement ou de réparation.

Les outils d'automatisation peuvent également prédire quels produits sont les plus susceptibles d'être retournés, ce qui aide les marques à se préparer et à minimiser les déséquilibres de stock.

4. Des partenariats fiables avec les 3PL et les transporteurs

La logistique inverse implique souvent plusieurs transporteurs et points de contrôle douanier. Un service de 3PL (Third Party Logistics) comme Postalparcel contribue à simplifier ce réseau en offrant des solutions unifiées dans tous les pays.

Pourquoi c'est utile :

- Gestion centralisée des retours.

- Traitement professionnel de la documentation internationale.

- Soutien intégré à l'exécution des commandes et à l'entreposage.

Travailler avec des experts permet de s'assurer que les déclarations mondiales respectent les normes de conformité et d'éviter des retards coûteux.

5. Élimination et recyclage durables

La logistique inverse est directement liée à la durabilité. Au lieu de jeter les produits retournés, les entreprises peuvent recycler les pièces, réutiliser l'emballage ou vendre des articles remis à neuf.

Des mesures efficaces en faveur du développement durable :

- Établir des partenariats avec des entreprises de recyclage locales.

- Mettre en œuvre des programmes de reprise des produits usagés.

- Encourager les clients à renvoyer les emballages pour qu'ils soient réutilisés.

Cela permet non seulement de réduire les déchets, mais aussi d'améliorer l'image environnementale de la marque, un argument de vente de plus en plus puissant sur le marché mondial.

6. Optimisation basée sur les données

Chaque produit retourné fournit des informations utiles. En analysant les données relatives aux retours, les entreprises peuvent découvrir des tendances telles que des défauts de produits, des problèmes de livraison ou l'insatisfaction des clients.

Ce qu'il faut analyser :

- Motifs de retour (défectueux, mauvaise taille, préférence).

- Régions avec des taux de retour plus élevés.

- Délai de traitement de la demande à la résolution.

Grâce à ces données, les équipes peuvent améliorer la qualité des produits et rationaliser les décisions en matière d'emballage ou de logistique, ce qui rend l'ensemble de la chaîne d'approvisionnement plus efficace.

Obstacles courants à une logistique inverse efficace

Même avec les meilleures intentions, chaînes d'approvisionnement mondiales faire face à des obstacles qui affectent les performances de la logistique inversée.

Les principaux défis sont les suivants :

- Les formalités douanières pour les retours sont compliquées.

- Frais d'expédition élevés pour des articles de faible valeur.

- Peu d'installations locales pour la réparation ou le recyclage.

- Qualité irrégulière du produit après retour.

Comment les surmonter :

- Utilisez les centres de retour locaux pour réduire la distance et les frais d'expédition.

- Automatiser les formulaires douaniers à l'aide d'un logiciel de logistique.

- Travailler en partenariat avec des reconditionneurs certifiés pour garantir des normes de produits cohérentes.

- Offrir des incitations aux clients qui choisissent des options de retour respectueuses de l'environnement.

Ces ajustements permettent de créer un réseau de retour plus rapide et plus rentable.

Le rôle de la communication dans la logistique inverse

Logistique inverse dépend d'une communication fluide entre les fournisseurs, les entrepôts et les clients. Lorsque toutes les parties échangent des informations en temps réel, les retours sont traités plus rapidement.

Mesures pratiques :

- Tenir les clients informés par e-mail ou SMS à chaque étape du retour.

- Veiller à ce que les équipes de l'entrepôt aient accès à des données de suivi actualisées.

- Maintenir des canaux ouverts avec les partenaires d'expédition.

La transparence élimine la confusion et les retards, transformant la frustration potentielle en satisfaction.

Tendances futures de la logistique inverse

La prochaine décennie apportera encore plus d'innovation à la logistique inverse dans la gestion de la chaîne d'approvisionnement. L'intelligence artificielle permettra de prévoir les volumes de retour et d'optimiser les itinéraires. La blockchain garantira une transparence totale pour chaque transaction. Les emballages durables et les partenariats de recyclage deviendront des pratiques courantes.

Les entreprises internationales investiront également dans des centres d'exécution et des centres inversés localisés afin de réduire les émissions et les délais de livraison. Ces stratégies tournées vers l'avenir aident les entreprises à rester compétitives dans un monde de plus en plus axé sur le développement durable.

Conclusion

La logistique inverse dans la gestion de la chaîne d'approvisionnement est plus qu'un processus technique : c'est un atout stratégique pour les entreprises internationales. Il permet aux entreprises de gérer les retours, de contrôler les coûts et de soutenir les objectifs environnementaux, tout en améliorant la fidélité des clients.

Les marques qui conçoivent aujourd'hui de solides systèmes de logistique inverse se démarqueront demain. Avec le soutien de partenaires tels que Postalparcel, les entreprises peuvent mettre en place des solutions de retour transparentes, durables et efficaces qui assurent la satisfaction des clients et le bon fonctionnement des chaînes d'approvisionnement.

La logistique inverse n'est pas un fardeau, c'est la base d'un commerce mondial plus intelligent, plus écologique et plus résistant.

Aperçu de l'industrie

nouvelles via la boîte de réception

Nulla turp dis cursus. Integer liberos euismod pretium faucibua