Leveraging OMS Logistics Tracking Data for Inventory Management and Demand Forecasting

Inventory mistakes can cost businesses thousands. Too much stock leads to high storage costs, while too little results in missed sales. That’s why smart companies today are using OMS logistics tracking data to improve how they manage inventory and predict demand. By turning raw logistics data into useful insights, companies can react faster, reduce waste, and make better decisions.

At postalparcel, we’ve helped brands of all sizes use OMS data to gain full visibility of their operations—from warehouse to customer door. This article explains how tracking data from your order management system (OMS) can be a powerful tool to keep your stock in balance and your supply chain ahead of the curve.

What Is OMS Logistics Tracking

OMS logistics tracking is the real-time monitoring and recording of order movement, status, and fulfillment activity across the supply chain. It includes updates from order creation to the moment goods reach the customer, giving managers a clear picture of every step.

Key Components

- Order creation and confirmation details

- Warehouse processing and picking progress

- Dispatch updates and carrier tracking information

- Final delivery notifications and customer receipt data

Most businesses already have access to this data, but few use it fully for inventory planning or forecasting.

Why It Matters

- Real-time data improves inventory accuracy and reduces errors.

- Helps identify slow-moving products before they become costly.

- Improves customer satisfaction with accurate delivery estimates.

- Makes it easier to react quickly when supply chain disruptions occur.

Using OMS logistics tracking is not just about knowing where a package is—it’s about understanding patterns that influence the entire supply chain and future decisions.

Using OMS Data for Better Inventory Management

Inventory management is all about keeping the right amount of stock at the right time. With help from OMS logistics tracking, companies can match supply with demand even during unpredictable market shifts.

Identify Stock Levels in Real Time

By pulling live updates from your OMS, you can see exactly which items are:

- In stock and ready to ship

- In transit between warehouses

- Awaiting pickup or processing

- Backordered or delayed

This visibility prevents overordering or overselling and keeps teams aligned across multiple locations.

Track Turnover Rates

OMS data shows how fast specific items move through your system. You can:

- Rank products by sell-through rate

- Flag slow-moving stock before it becomes dead inventory

- Adjust minimum stock levels dynamically to save on storage costs

Tracking trends instead of relying only on past reports keeps inventory lean and efficient.

Automate Reordering Triggers

Combine inventory thresholds with live tracking updates to create smart reordering rules. For example:

- Automatically place a restock order when stock drops below a set level.

- Delay restock if high returns are detected for that product.

- Prioritize reorders based on supplier lead times and delivery reliability.

This allows your system to self-correct, keeping stock balanced without manual oversight.

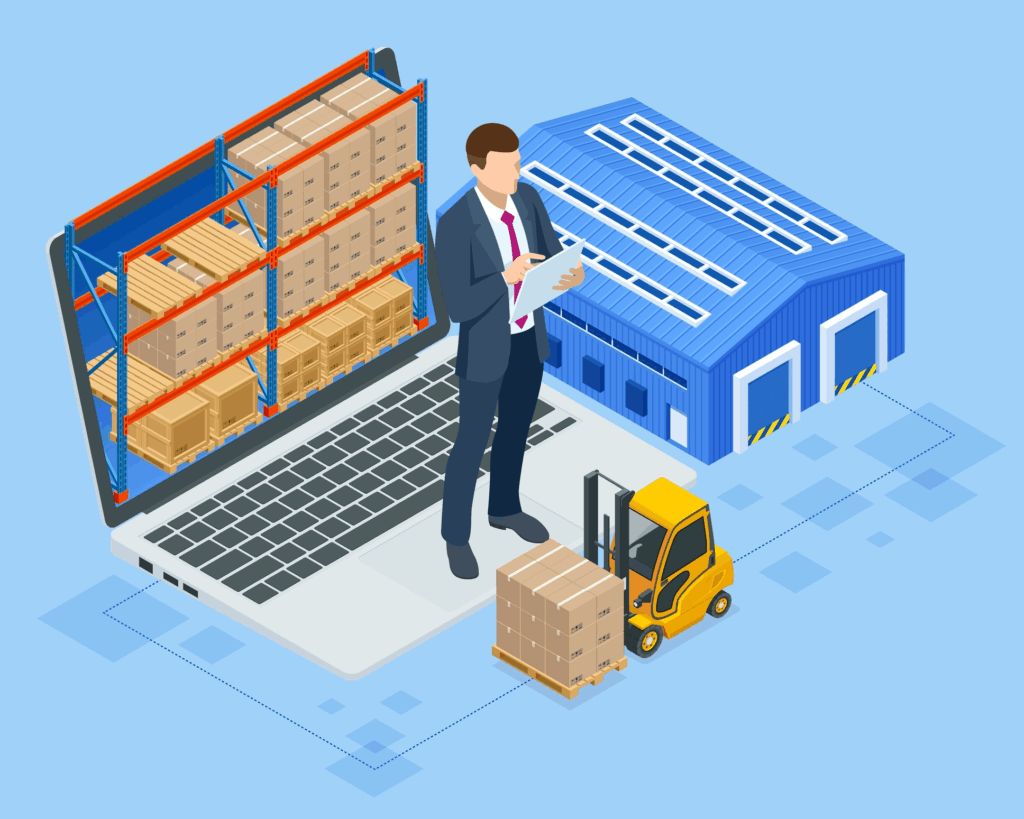

Improve Multi-Warehouse Coordination

Large companies often operate multiple warehouses. OMS logistics tracking gives a clear picture of where each product is located, enabling quick stock transfers and reducing the risk of one location running out while another has surplus.

Using OMS Data for Demand Forecasting

Forecasting used to depend mainly on historical sales numbers. Today, OMS logistics tracking adds a new layer of accuracy by providing live information on shipment flow, customer behavior, and regional demand.

Analyze Delivery Timelines

Knowing how long it takes for products to reach customers helps you predict future lead times more reliably. By measuring:

- Average fulfillment times

- Carrier performance by region

- Delay patterns during holidays or supply disruptions

Your forecasts reflect real-world conditions, not just spreadsheets.

Monitor Buying Behavior

Your OMS records valuable customer activity, such as:

- Abandoned orders and repeat purchases

- Peak order times during the day or week

- Seasonal buying trends across different product categories

These insights reveal where demand will grow and where stock should be allocated in advance.

Regional Forecasting

By comparing order volume and delivery success across different areas, you can:

- Shift high-demand items closer to regions with faster turnover

- Move slower items to lower-cost warehouses

- Adjust regional marketing campaigns to match local buying patterns

The more detailed your OMS data, the smarter your inventory placement and forecasting.

Plan for Seasonal Peaks

During major shopping events or holiday periods, OMS logistics tracking helps you anticipate spikes in demand. Real-time order and shipping data allow teams to prepare extra stock and allocate resources before peak times arrive.

Postalparcel’s OMS Logistics Expertise

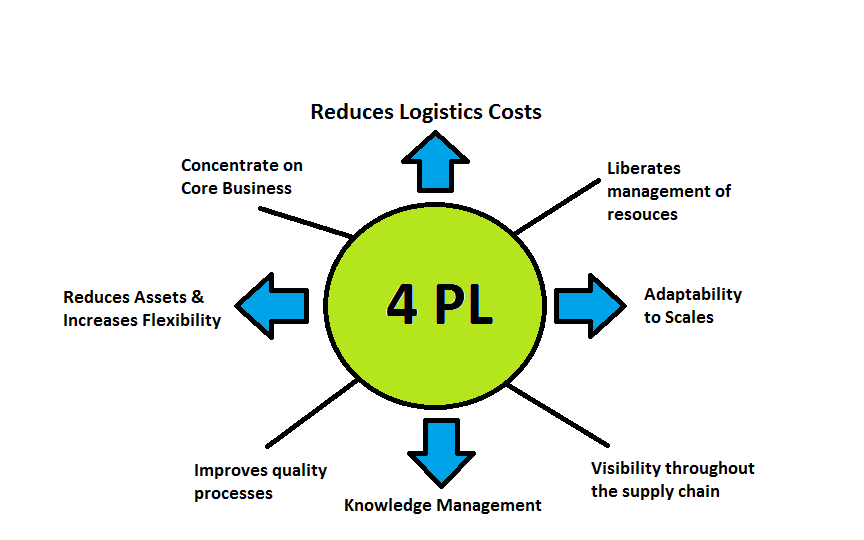

At postalparcel, we help companies turn OMS logistics tracking into a real operational advantage. We don’t just connect systems—we design strategies to make those systems work together for growth and efficiency.

Our Key Services

- Unified Dashboards: Track stock, shipments, and delivery performance in one place.

- API Integration: Link OMS with warehouses, carriers, and ERP systems for seamless updates.

- Smart Alerts: Receive warnings before a stockout or major shipping delay.

- Analytics Support: Transform raw OMS data into actionable insights for inventory and demand planning.

Our 4PL and OMS logistics services allow businesses to scale operations while staying in control. Whether you manage retail, eCommerce, or multi-warehouse networks, our solutions help you turn data into confident decisions.

Real Business Impact

Companies using OMS logistics tracking for forecasting and inventory control have reported:

- Up to 35% fewer stockouts across multiple regions

- 25% faster replenishment cycles that cut lead times

- 18% lower holding costs due to more accurate stocking

- Better promotion planning based on live supply data

These results show how much value is hidden in OMS data that many companies overlook.

Conclusion

OMS logistics tracking is not just a way to follow packages. It is a strategic tool for smarter inventory management and more accurate demand forecasting. By collecting and analyzing order data in real time, businesses can reduce risk, improve efficiency, and respond quickly to market changes.

With postalparcel as your partner, OMS data becomes a clear path to growth. From warehouse planning to customer delivery, we help companies build a supply chain that adapts in real time and scales with confidence. The information you need to avoid stock surprises and demand swings is already flowing through your OMS—you only need the right tools and expertise to turn that data into action.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua