Real-Time Inventory Visibility: Key Logistics Technologies Driving Change

Today’s e-commerce and supply chain environment is moving faster than ever. Customers expect accurate delivery dates, businesses need to reduce operational costs, and competition is intensifying. In this context, real-time inventory visibility has become a vital advantage for companies managing complex logistics networks.

This article explains what real-time inventory visibility means, why it matters for logistics performance, and the key technologies driving this transformation in the global supply chain.

1. What is Real-Time Inventory Visibility?

Real-time inventory visibility means knowing exactly what you have in stock, where it is, and its status at any given moment across your warehouses, stores, and in-transit shipments. Unlike traditional systems that update data only once daily or after batch processes, real-time systems continuously synchronize inventory data across all channels and locations.

For example, if a product is picked in your warehouse, the system updates immediately, preventing overselling and ensuring accurate availability for customers.

2. Why Real-Time Inventory Visibility Matters

2.1 Meeting Customer Expectations

Today’s online shoppers demand accurate stock information. If your website shows an item as available but it is actually out of stock, customers will lose trust in your brand. Real-time inventory data prevents these errors, supporting better shopping experiences and repeat purchases.

2.2 Enabling Omnichannel Fulfillment

Retailers selling through multiple channels – e-commerce stores, physical stores, and marketplaces – need a unified inventory view to avoid overselling and to fulfill orders efficiently. Real-time visibility ensures:

- Buy Online, Pick Up In Store (BOPIS) is seamless

- Online orders can be fulfilled from the nearest location

- Stock levels are automatically updated across all channels after each sale

2.3 Reducing Costs and Improving Efficiency

Better visibility means you avoid overstocking, which ties up cash flow, and understocking, which leads to lost sales. It also improves warehouse operations by optimizing picking routes, reducing labor costs, and ensuring products are stored in the most efficient locations.

2.4 Enhancing Demand Forecasting

Accurate, real-time data enables companies to analyze trends quickly and adjust purchasing plans before issues arise. This reduces the risk of stockouts during peak seasons and minimizes excess inventory during slow periods.

3. Key Technologies Driving Real-Time Inventory Visibility

3.1 Internet of Things (IoT) and RFID

RFID (Radio Frequency Identification) tags and IoT sensors are revolutionizing warehouse tracking. Unlike barcodes, RFID tags do not require line-of-sight scanning, allowing entire pallets to be scanned instantly as they enter or leave a zone.

- Benefits: Faster receiving, reduced picking errors, real-time location tracking

- Example: Leading retailers use RFID to track apparel inventory at the item level, reducing out-of-stocks by up to 50%.

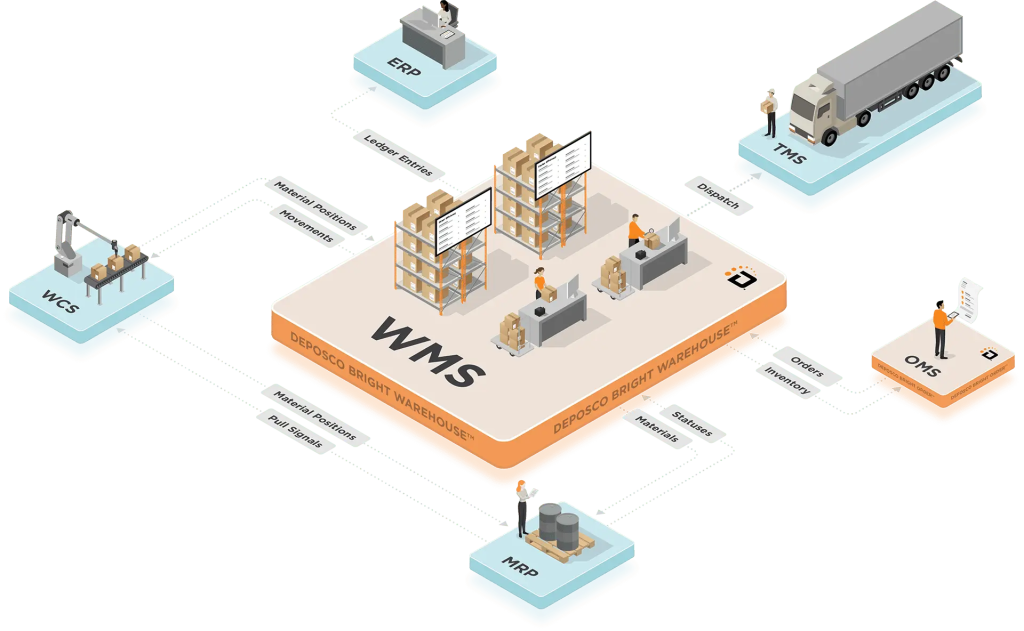

3.2 Advanced Warehouse Management Systems (WMS)

Modern WMS platforms integrate with RFID, IoT devices, and your e-commerce systems to update inventory data instantly. They provide:

- Real-time dashboards of stock levels and order status

- Optimized picking and replenishment processes

- Automated stock adjustments when items are picked, packed, or shipped

3.3 Cloud-Based Inventory Management

Traditional systems hosted locally often create data silos. Cloud-based inventory systems offer:

- Centralized data accessible anywhere in real time

- Easier integration with multiple sales channels and 3PL partners

- Scalability to manage growing SKU counts and new warehouse locations

3.4 Artificial Intelligence and Machine Learning

AI algorithms analyze real-time inventory data to:

- Predict demand trends for better purchasing decisions

- Optimize warehouse slotting for faster picking

- Automate replenishment based on sales velocity

Example: Large retailers like Walmart use AI-driven inventory forecasting to adjust stock levels daily, ensuring high availability without excess storage costs.

3.5 Blockchain Technology

Blockchain creates secure, transparent records of inventory movements across all parties in the supply chain. This is especially useful in complex international logistics involving multiple stakeholders.

- Benefits: Increased transparency, reduced reconciliation errors, enhanced trust between suppliers and retailers

- Example: Blockchain platforms track food products from farm to shelf, ensuring freshness and traceability.

4. Challenges in Implementing Real-Time Inventory Visibility

While the benefits are clear, companies often face challenges:

- Integration Complexity: Connecting old ERP systems with new cloud platforms, IoT devices, and WMS solutions requires planning and technical expertise.

- Data Accuracy: Technology cannot compensate for incorrect data entry or labeling errors; process discipline is still needed.

- Cost: Initial investments in RFID, IoT, AI tools, and training can be significant, though they pay off long-term.

- Change Management: Teams must adapt to new systems and workflows, which can take time and training.

5. Future Outlook

As 5G networks roll out globally, connectivity speeds will increase, enabling even more precise real-time inventory tracking, even for mobile warehouses or delivery fleets. In addition, AI will further automate decision-making, allowing inventory systems to adjust stock levels and order flows automatically based on live demand data.

Companies that invest in real-time inventory visibility will:

- Improve operational efficiency

- Reduce logistics costs

- Enhance customer satisfaction

- Gain a competitive advantage in their market

6. Conclusion

Real-time inventory visibility is no longer just a competitive advantage – it is becoming a necessity in e-commerce and logistics. Technologies such as IoT, RFID, cloud-based systems, AI, and blockchain are driving this shift, transforming how inventory is tracked, managed, and optimized across the supply chain.

Businesses that embrace these innovations now will be better positioned to deliver on customer expectations, manage costs effectively, and build agile, resilient supply chains for the future.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua