Reverse Logistics Courier Tracking Hacks for Profit

Reverse logistics courier tracking unlocks powerful data that can cut costs, speed up returns, and strengthen customer loyalty. Every scan on the journey from the customer back to the warehouse captures details that reveal where processes slow down, where expenses rise, and where service can improve. By using this data to act quickly, companies can turn the challenge of handling returns into a chance to grow. Postalparcel proves how analyzing tracking information transforms routine return updates into business insights that drive smarter decisions and a better post-purchase experience.

Understanding Reverse Logistics Courier Tracking

Reverse logistics covers the movement of goods from the customer back to the seller or manufacturer. Courier tracking records each point of the journey in real time. Every scan, from the moment a return label is created to the final arrival at the warehouse, generates data that can be analyzed.

Key Stages of the Return Journey

- Return Request: A customer initiates a return and prints a label.

- First Scan: The courier records the package when it is dropped off or collected.

- Transit Updates: Each sorting center and checkpoint adds a scan to the tracking record.

- Warehouse Confirmation: The package reaches the warehouse and triggers a refund or replacement.

These simple events create a detailed map of the reverse supply chain. Reverse logistics courier tracking transforms this map into valuable insight.

Turning Tracking Data into Actionable Insights

The power of reverse logistics courier tracking lies in analyzing the data, not just storing it. Instead of using tracking only to confirm delivery, companies can uncover patterns that drive better decisions.

Detect Delays and Bottlenecks

Careful review of time stamps between checkpoints reveals where packages slow down. Companies can work with specific carriers or hubs to reduce those delays and speed up the entire return process.

Control and Reduce Costs

Tracking data highlights which products or regions create the highest return expenses. Businesses can identify the root causes—such as frequent defects or unclear sizing—and adjust production or marketing strategies to lower costs.

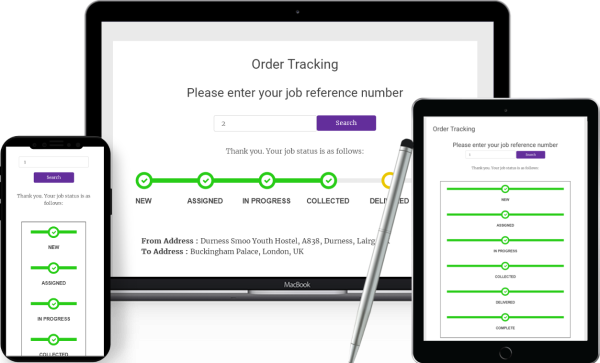

Strengthen Customer Communication

Real-time tracking information allows brands to send automatic updates. Customers know exactly when their return has been received and when to expect a refund. This clear communication reduces support calls and builds trust.

Enhancing the Customer Experience

A smooth return process can turn an unhappy buyer into a repeat customer. Reverse logistics courier tracking gives customers confidence that their package is moving quickly and that their refund or replacement will arrive on time.

Practical Ways to Improve Experience

- Instant Links: Include direct tracking links in return emails.

- Automated Updates: Send messages at key milestones, such as pick-up and warehouse arrival.

- Clear Timelines: Provide an accurate refund schedule based on actual tracking data.

These small steps transform a potential source of frustration into a moment of reassurance.

Supporting Sustainable Operations

Handling returns has a direct impact on the environment. Each trip back to the warehouse consumes energy and resources. Reverse logistics courier tracking data can help reduce that impact.

- Identify products with high defect rates and improve quality control.

- Spot opportunities to reuse or recycle packaging materials.

- Optimize return routes to reduce unnecessary transport miles and lower emissions.

By using tracking data, companies can make their operations both greener and more efficient.

The Role of Postalparcel

Postalparcel offers a clear example of how to use reverse logistics courier tracking for business growth. Centralizing data from many carriers provides a single platform where brands can view every return in real time. This integrated view helps teams respond faster, cut processing costs, and deliver a smoother post-purchase experience. Postalparcel proves that accurate tracking is not only about knowing where a package is but also about unlocking insights that support long-term success.

Building a Competitive Advantage

Reverse logistics courier tracking is now a strategic asset. Companies that collect and analyze tracking data can improve operations, reduce expenses, and keep customers satisfied.

Key Takeaways

- Identify and Fix Delays: Use tracking data to pinpoint weak points in the return chain.

- Improve Products and Services: Spot frequent return reasons and act on the feedback.

- Communicate Proactively: Build trust by giving customers timely updates.

- Lower Environmental Impact: Plan efficient routes and reduce waste.

Businesses that view reverse logistics courier tracking as more than a routine process will discover opportunities for growth and innovation. By following the example set by Postalparcel, any brand can turn return data into a source of competitive strength and deliver better value to both customers and the environment.

conclusion

Reverse logistics courier tracking is no longer just a back-end process. It is a strategic resource that can shape cost control, customer loyalty, and sustainable practices. By studying tracking data, brands gain a deeper understanding of return patterns and areas for improvement. Companies that follow the example of Postalparcel, using this information to make quick, data-driven decisions, will not only cut expenses but also create a smoother post-purchase experience. Turning reverse logistics courier tracking into a core business tool opens the door to stronger operations, happier customers, and long-term growth.

FAQ

1. What is the main purpose of reverse logistics?

Reverse logistics handles the process of moving goods from customers back to sellers or manufacturers, focusing on returns, repairs, recycling, and proper disposal.

2. How does reverse logistics work?

It starts when a customer initiates a return. The product is picked up by a courier, scanned at various checkpoints, and transported back to a warehouse or repair center, with each step tracked in real time.

3. What are the main types of reverse logistics?

The key types include product returns, refurbishment and repair, recycling and waste management, and asset recovery such as reusable packaging or parts.

4. Is reverse logistics just for returns?

No. It also includes recycling, reusing materials, refurbishing items for resale, and recovering valuable components to reduce waste and cost.

5. How does Amazon handle reverse logistics?

Amazon provides customers with return labels and multiple drop-off options. Courier tracking ensures each return is scanned and updated until it reaches the Amazon fulfillment center.

6. What are the biggest problems in reverse logistics?

Common challenges include high transportation costs, tracking inefficiencies, managing damaged goods, and maintaining customer satisfaction during the return process.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua