WMS and ERP: Key Differences, Synergies, and How to Choose the Right System for Your Business

Choosing the right software for your warehouse may not seem critical at first. Still, it has a significant impact on both the financial and operational health of your business. Whether deciding between a best-of-breed Warehouse Management System (WMS) or an existing module within your Enterprise Resource Planning (ERP) system, understanding which solution better fits your business needs is essential. This article will guide you through the key factors to consider when choosing between these two systems and help you determine the most effective solution for your warehouse operations.

1. Introduction

In the era of digital transformation, the efficiency of your supply chain heavily depends on the systems you implement. Warehouse Management Systems and Enterprise Resource Planning (ERP) systems are crucial in streamlining operations and optimizing processes. However, understanding the distinctions between them—and how they complement each other—is key to making an informed decision on whether to use them independently or integrate them for a more comprehensive solution.

2. Definitions

Before diving into their differences and synergies, let’s start by understanding the roles of these two systems:

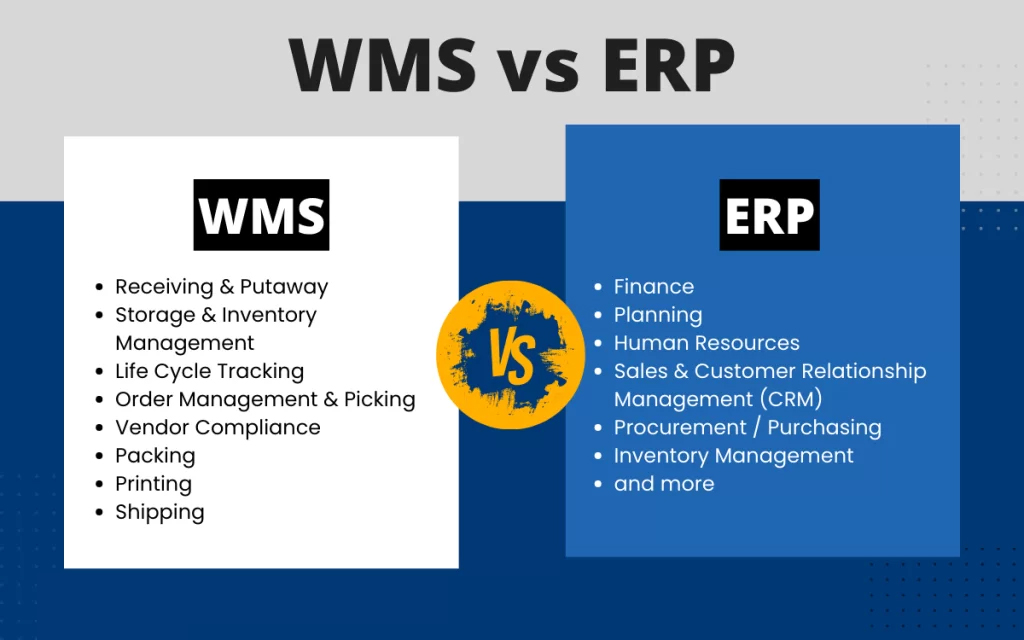

- WMS (Warehouse Management System): The “execution layer” of warehouse operations, WMS focuses on real-time inventory tracking, order picking, and ensuring that goods are moved efficiently through the warehouse. It handles the day-to-day operations of warehouse management, providing managers with up-to-date information on stock levels and helping improve warehouse efficiency.

- ERP (Enterprise Resource Planning): The “planning layer” of a business, ERP systems integrate core business processes such as financials, procurement, manufacturing, and human resources into a single platform. While WMS deals with the logistics and execution at the warehouse level, ERP provides a high-level overview of the entire enterprise, ensuring that all functions are aligned and coordinated.

3. Key Differences

Here’s a breakdown of the main differences between WMS and ERP systems:

| Aspect | WMS | ERP | Synergy Role |

|---|---|---|---|

| Primary Focus | Real-time inventory and warehouse management | Business resource planning, including finance and production | WMS supports ERP with real-time data; ERP gives overall instructions to WMS |

| Core Functionality | Inventory tracking, order picking, warehouse optimization | Financial management, procurement, production coordination | WMS enables real-time decisions; ERP manages high-level strategy |

| Integration Scope | Warehouse-specific operations | Entire enterprise resource management | WMS feeds ERP with data for financial and operational adjustments |

While WMS is highly specialized for warehouse operations, ERP offers broader organizational functionality. When integrated, these systems can provide a seamless data flow between various business functions.

4. Synergies Between WMS and ERP

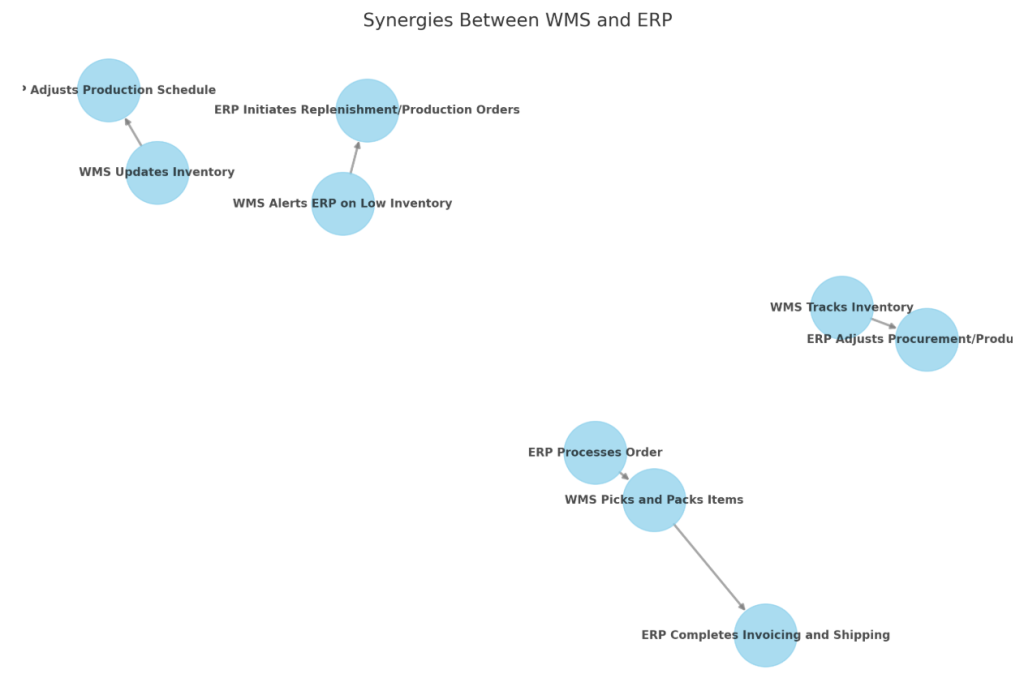

When used together, WMS and ERP provide tremendous synergy. Here are some areas where the two systems collaborate to drive efficiency:

4.1 Inventory Level Optimization

WMS provides real-time inventory data that can be fed into the ERP system. This helps the ERP system dynamically adjust procurement and production plans based on accurate, up-to-the-minute information.

- Example: WMS tracks raw materials and semi-finished goods in a manufacturing environment, while ERP ensures that overstocking or stockouts are avoided based on real-time data.

4.2 Inbound Process Collaboration

ERP sends inbound shipment schedules to WMS. Once goods are received, WMS updates the inventory, and this information is synchronized with the ERP system, allowing businesses to adjust their operations accordingly.

- Example: A factory receives raw materials, and ERP adjusts the production schedule based on real-time inventory updates from WMS.

4.3 Order Fulfillment Closed Loop

ERP handles order creation and dispatch, while WMS picks and packs the items. Afterward, the ERP system manages invoicing and shipping, creating a full circle of order fulfillment from start to finish.

- Example: A customer orders online; ERP processes the order, WMS picks and packages the items, and ERP completes the invoicing and shipping process.

4.4 Agile Replenishment and Production Support

WMS can alert ERP systems when inventory levels are low, prompting the system to initiate replenishment or adjust production schedules.

- Example: A Just-In-Time (JIT) inventory system relies on WMS to signal when materials are running low, prompting ERP to initiate production or purchase orders.

5. How to Choose and Integrate?

Independent Use Scenarios:

- WMS Alone: If your primary goal is to optimize warehouse management, WMS alone is often sufficient. It provides deep control over inventory, picking, and warehouse operations without needing the full suite of enterprise functions that ERP offers.

- ERP Alone: For businesses primarily focused on managing finances, human resources, or production coordination, an ERP system may be all that’s needed.

Signals that Integration is Necessary:

- Cross-Departmental Data Delays: When the warehouse, finance, and procurement teams cannot access real-time data from each other.

- Lack of Visibility: If there’s a lack of transparency around inventory levels, order statuses, or resource allocation.

- Increased Errors: If the order error rate rises due to disconnected systems.

Implementation Pathways:

- API Integration: APIs are a common way to integrate WMS and ERP, enabling real-time data synchronization. For example, SAP and Oracle offer WMS modules that can be integrated into ERP systems to ensure seamless data flow.

- Middleware Solutions: Solutions like Electronic Data Interchange (EDI) or Internet of Things (IoT) platforms can be used as intermediaries to bridge WMS and ERP systems.

- Unified Vendor Solutions: Companies like Infor Nexus offer integrated ERP and WMS suites, which reduce the complexity of implementation and maintenance.

6. Future Trends

Advancements in technologies such as AI and blockchain heavily shape the future of WMS and ERP integration.

6.1 AI-Driven Synergy

AI allows for the dynamic adjustment of supply chain operations by combining WMS’s real-time data with ERP’s predictive analytics. This can lead to faster, more accurate decision-making.

- Example: AI could help improve warehouse space utilization and dynamically adjust procurement or production schedules based on historical data patterns.

6.2 Blockchain Applications

Blockchain can secure data shared between ERP and WMS systems, especially for cross-border logistics. With blockchain, businesses can ensure the integrity of inventory data and track shipments in real time.

- Example: Blockchain could provide an immutable record of every inventory movement, improving data transparency and security in global supply chains.

By understanding the key differences and synergies between WMS and ERP, businesses can decide whether to implement them separately or integrate them. Both systems offer significant advantages, and when used together, they create a more efficient and responsive supply chain capable of meeting the demands of modern business operations.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua

[…] with ERP, WMS, and customer […]