冷链仓储和 WMS:利用智能技术克服挑战

技术在冷链物流中的关键作用

想象一下失去 $ 价值 500 000 美元的疫苗 因为 30 分钟的温度偏差。这不是假设--如果没有适当的管理,这就是冷链物流的日常风险。

在当今全球化的供应链中,温控仓储已成为关键任务:

- 救生药品和疫苗

- 新鲜和冷冻食品供应

- 敏感的生物技术和化学产品

传统的仓储方法已无法满足当今的需求 精度、合规性和 效率 要求。这就是先进的 仓库管理系统(WMS) 正在通过以下方式彻底改变冷链操作

- 实时温度监控

- 自动跟踪合规情况

- 人工智能驱动的库存优化

冷链仓储为何具有独特的挑战性

冷链物流面临多重挑战,每项挑战都需要精确的解决方案:

1.高风险的温度控制问题

- 2-8°C疫苗与-25°C冷冻食品 - 每种产品都有确切的温度要求。

- 仅仅是 15 分钟偏差 超出范围就会毁掉整批货物。

- 多区设施(冷冻室、冷藏室、常温室)增加了操作的复杂性。

2.合规雷区

- 条例 | 影响 | 失败的后果

- 美国食品和药物管理局 21 CFR 第 11 部分 | 电子记录 | 产品召回

- 欧盟 GDP 准则 | 交通管制 | 法律处罚

- 危害分析和关键控制点 | 工艺文件 | 设备停机

3.传统系统的可见性差距

- 42% 家冷链企业报告库存不准确 (GS1, 2023)。人工跟踪往往会导致:

- 过期产品废料(FEFO 故障)

- 召回期间损失的批次

4.人与能源的挑战

- 工人在以下情况下失去效率 -25°C 环境.

- 制冷 消耗 60-70% 设施能源成本。

现代 WMS 解决方案如何变革冷链运营

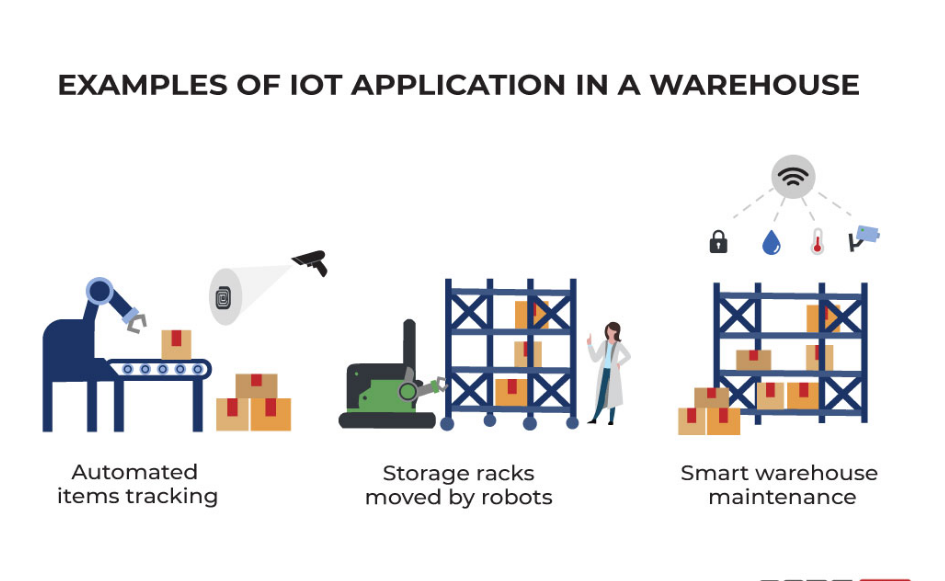

现代 WMS 解决方案通过实施创新技术来应对这些挑战,以确保无缝操作。通过使用尖端的解决方案,如 物联网, 人工智能和 射频识别这些系统提供了切实的改进:

1.智能温度监测(物联网+人工智能)

- 实时监控:物联网传感器可持续跟踪所有存储区域的温度波动。其结果是 99.9% 温度符合性这样可以防止代价高昂的变质,并确保疫苗、药品和新鲜食品等产品保持在最佳温度范围内。

- 预测分析:人工智能利用历史数据和趋势,在潜在的温度偏差发生之前进行预测。例如,人工智能可以根据先前的模式预测冷却系统故障,触发先发制人的行动,以保持稳定的存储条件。

- 成果:实施这些系统将导致 30% 减少产品损耗在整个供应链中,提高产品的完整性并最大限度地减少浪费。

2.点击 3 次即可实现自动合规

- 数字审计跟踪:WMS 系统自动记录每笔交易、温度数据和产品移动情况。这些记录使用 区块链验证提供 不可更改的审计线索 确保合规性和透明度。

- 自动生成合规报告:对于监管检查(如 FDA、GDP),WMS 可自动生成必要的报告。这大大减少了记录合规性所需的人工工作,使企业更容易保持审计就绪状态。

- 电子签名:基于角色的访问控制可确保只有获得授权的人员才能批准和签署文件,从而减少人为错误并维护安全的文件流程。

- 成果:这些自动功能可确保 100% 审计准备在节省时间和资源的同时,确保无缝满足所有监管要求。

3.军用级可追溯性

- RFID 标签:每件产品都有 RFID 标签提供以下方面的实时数据

- 温度历史:确保产品在整个运输过程中保持在规定的温度范围内。

- 地点时间表:跟踪产品在不同设施和运输阶段的准确位置。

- 处理条件:记录产品在每个阶段的处理方式,确保产品符合特定的质量控制标准。

- FEFO 自动执行:管理系统自动执行 先到期、先出库(FEFO) 库存管理,确保最接近保质期的产品优先发货,减少浪费,优化产品轮换。

- 成果:这一级别的 军用级可追溯性 确保每个产品的完全可视性和责任性,提高合规性,防止在处理、运输和存储过程中出现错误。

4.能源和劳动力优化

- 动态插槽:人工智能驱动的 WMS 通过将温度要求相似的产品放置在更近的位置来优化存储,从而最大限度地减少不必要的能源消耗。例如,将经常存取的物品存放在需要不断调整温度的区域。

- 预测性补货:该功能可分析库存水平和订单预测,以预测何时何地需要补货,从而减少频繁的人工检查,最大限度地减少库存过多或缺货现象。

- 轮班警报:WMS 系统监控冷藏区等挑战性环境中的劳动效率,确保工人轮换以保持安全和生产率。自动警报有助于防止工人疲劳,减少安全事故。

- 成果:这些优化有助于

- 减少 22% 能源成本 通过改进仓库布局和节能措施。

- 35% 降低劳动力成本 这得益于更智能的调度和预测性库存管理。

- 40% 安全事故减少提高员工福利。

真实世界的成功案例:行动中的技术

案例 1:全球疫苗分销商

- 挑战: 18% 变质率 在大流行病疫苗推广期间,由于温度偏差而造成的损失。

- 解决方案: 基于云的 WMS 系统,带物联网监控功能 用于实时温度跟踪和预测警报。

- 成果:

- ▼ 32% 减少浪费

- ▲ 99.8% 达标率

- ✓ 100% 批次召回准备就绪

案例 2:冷冻食品零售商

- 挑战: 每年 $2M 的能源成本 以及旺季时订单执行效率低下的问题。

- 解决方案: 人工智能驱动的插槽 和 门传感器 以优化存储,减少能源浪费。

- 成果:

- ▼ 22% 节能

- ▲ 15% 更快完成订单

冷链 WMS 的未来:3 个改变游戏规则的趋势

- 预测问题的人工智能

- 机器学习预测 设备故障 和 需求激增 (如疫苗接种活动)发生之前,进行主动管理,减少对供应链的干扰。

- 实现完全信任的区块链

- 不可更改的记录 从制造商到患者,确保数据的完整性。 智能合约 自动验证合规性,提高透明度,减少人工执行合同的工作量。

- 自我调整的 "绿色仓库"

- 太阳能制冷系统 和自动化 日光采集 有助于降低能耗。

- 碳足迹跟踪 使企业能够衡量其对环境的影响并优化能源使用。

WMS 势在必行

数字不会说谎--使用 WMS 进行冷链管理的企业都能实现:

- ✓ 30-50% 减少产品废料

- ✓ 100% 审计准备

- ✓ 20-35% 节约运行成本

随着监管的收紧和利润的缩减,问题不在于是否要实施 WMS - 关键在于转型的速度。未来属于仓库:

- 传感器自我思考

- 自动合规

- 完美保存每个产品的历程

行业洞察

收件箱消息

Nulla turp dis cursus.整体释放,预留空间

[...] 冷链监控:利用物联网传感器保持符合温控存储要求。[...]