Integrate GS1 Label Printing with ERP or WMS Easily

In today’s fast-paced supply chain environment, accuracy and traceability are non-negotiable. Businesses are increasingly adopting standardized labeling solutions to maintain consistency across global operations. One such standard is the GS1 label, which provides a universally recognized format for identifying products, shipments, and logistics units. Integrating GS1 label printing directly into your ERP (Enterprise Resource Planning) or WMS (Warehouse Management System) not only enhances operational efficiency but also ensures compliance with trading partner and regulatory requirements.

This article explores the benefits, key considerations, and practical steps for integrating GS1 label printing into your enterprise systems.

What Is a GS1 Label?

A GS1 label is a barcode-based labeling standard developed by the global GS1 organization. These labels typically include data such as GTINs (Global Trade Item Numbers), serial numbers, batch numbers, expiration dates, and shipping information. GS1 barcodes—such as GS1-128 and DataMatrix—are commonly used across various industries, including retail, healthcare, logistics, and manufacturing.

GS1 labels ensure that products can be scanned, identified, and traced consistently across the supply chain, from supplier to retailer to end customer.

Why Integrate GS1 Label Printing into Your ERP or WMS?

Many organizations rely on standalone label design and printing tools, but this approach often leads to manual work, disconnected data, and higher error rates. Integrating GS1 label functionality into your ERP or WMS system solves these problems and brings multiple advantages:

1. Data Consistency

With integration, label data—such as product descriptions, lot numbers, and expiration dates—is automatically pulled from your existing ERP or WMS database. This eliminates double entry and reduces the risk of human error.

2. Real-Time Printing

Labels can be triggered automatically during operational workflows, such as during goods receipt, order picking, or packing. This ensures that labels are generated at the right time with the correct data.

3. Compliance and Traceability

Integrated GS1 labels help meet industry-specific traceability requirements. For example, in pharmaceuticals, GS1-compliant serialization is critical for tracking medicine through the supply chain.

4. Scalability

As your operations grow, a system-integrated label printing process can scale with ease, supporting multiple facilities, languages, and label types.

Key Integration Scenarios

Different business operations require different integration models. Here are three common scenarios:

1. On-Demand Printing from ERP Transactions

A popular approach is to trigger label printing during ERP transactions such as receiving, shipping, or production order confirmation. The ERP system sends key data to the label printer or label management system, which generates and prints the GS1 label.

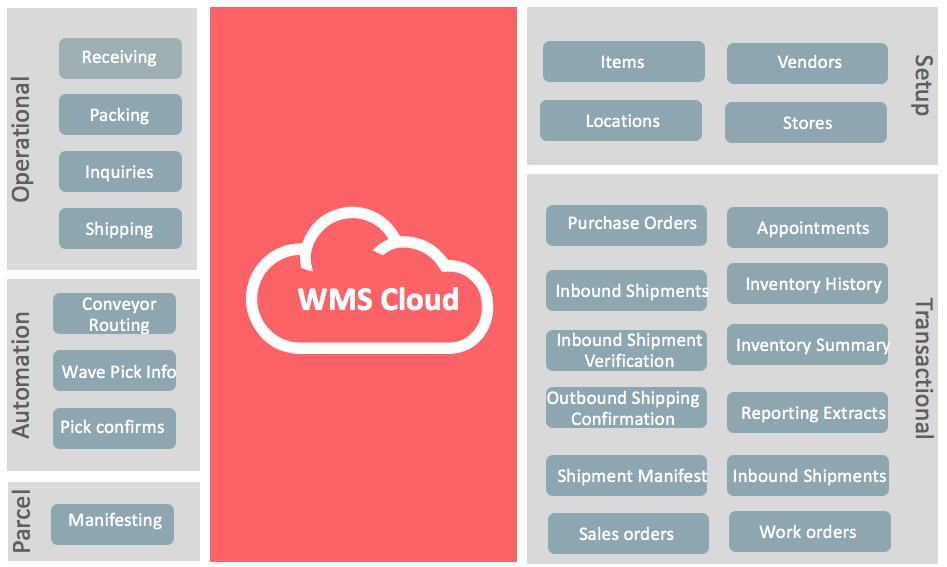

2. Automated Label Generation in WMS Workflows

In high-volume environments, labels must be printed automatically during warehouse activities like picking or packing. Integration allows the WMS to initiate printing in real-time based on scanned barcodes or system triggers.

3. Integration with Label Management Software

Some companies use third-party label software like NiceLabel, BarTender, or Loftware. These tools can be connected to ERP or WMS platforms via APIs, allowing centralized label design while leveraging real-time system data.

Steps to Integrate GS1 Label Printing

Step 1: Define Your Label Requirements

Begin by identifying which products, shipments, or packaging levels require GS1 labels. Determine the type of data that must appear—GTINs, batch codes, dates, etc.—and ensure your systems store this information accurately.

Step 2: Choose the Right Label Design Tool

Select a label design tool that supports GS1 standards. Ensure it has the ability to integrate with your ERP or WMS through native connectors, APIs, or middleware.

Step 3: Map ERP/WMS Data Fields to Label Templates

Work with your IT or implementation team to map database fields (e.g., item number, location, order ID) to corresponding fields in the label template. This mapping enables dynamic label generation during transactions.

Step 4: Configure Trigger Points

Set up printing triggers within your ERP or WMS. This could be based on events such as:

- Creation of a shipping document

- Completion of a work order

- Receipt of inbound goods

Trigger rules should also define which printer to use and which label template to apply.

Step 5: Test and Validate

Conduct thorough testing to validate the accuracy of label content, barcode scannability, and system response. Ensure labels meet GS1 formatting guidelines and partner requirements.

Step 6: Train Your Team

Once the system is live, train warehouse and production staff on how the integrated label process works. This includes handling exceptions, reprints, and printer maintenance.

Best Practices for Smooth Implementation

- Use centrally managed label templates to ensure standardization.

- Keep your GS1 Company Prefix and GTIN records up to date.

- Establish a clear change control process for updating labels or mappings.

- Monitor label printing performance and error logs regularly to detect issues early.

- Work with GS1-trained professionals if your industry has specific compliance rules (e.g., food traceability or healthcare serialization).

Final Thoughts

Integrating GS1 label printing into your ERP or WMS system is more than a technical upgrade—it’s a strategic improvement to how your business handles identification, traceability, and compliance. By linking your label process directly with operational data, you reduce errors, save time, and meet growing supply chain demands with confidence.

As global commerce becomes more standardized and regulated, having a GS1-compliant, system-driven labeling process is no longer optional—it’s essential.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua