GS1 Barcoding for Pallet and Case-Level Logistics Tracking

Efficient logistics tracking is no longer a competitive advantage—it’s a baseline expectation. As supply chains become more complex and globalized, businesses need reliable, standardized systems to monitor and manage inventory movement across every journey step.

GS1 barcoding, a globally recognized system for encoding supply chain information, is critical in pallet and case-level tracking. This article will explore how GS1 barcodes work, why they’re essential in modern logistics, and how your business can implement them for more accurate, real-time visibility across your operations.

What Is GS1 Barcoding?

GS1 is a not-for-profit global organization that develops and maintains standards for business communication. The most widely known of these standards is the GS1 barcode, which uniquely identifies products, cases, and pallets in supply chains worldwide.

At its core, GS1 provides:

- Global Trade Item Numbers (GTINs)

- Serial Shipping Container Codes (SSCCs)

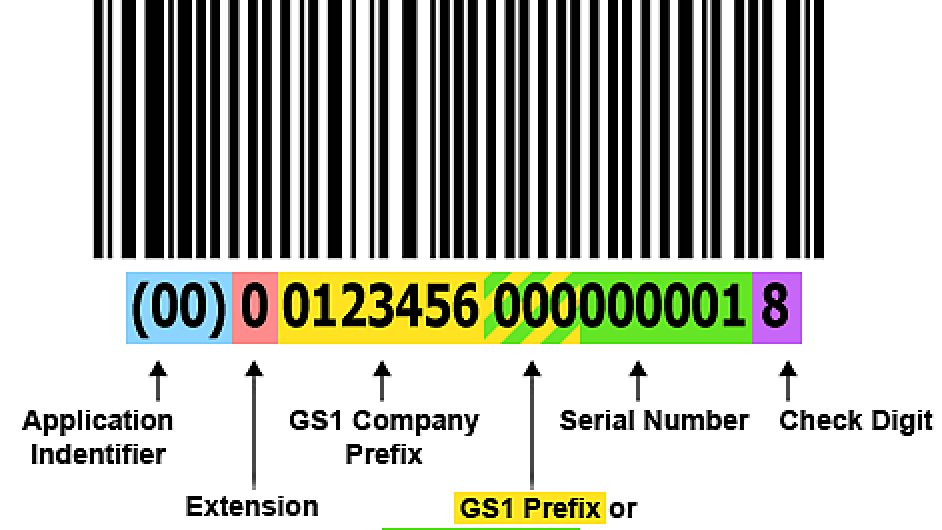

- Application Identifiers (AIs)

- Data Matrix and 1D/2D barcodes

These identifiers and structures allow every item, case, or pallet to be tracked precisely through scanning and database integration.

Why Use GS1 for Pallet and Case Tracking?

✅ Standardization Across Partners

Using GS1 barcodes ensures everyone in your supply chain—manufacturers, distributors, 3PLs, and retailers—is on the same page. A pallet or case labeled with a GS1-compliant barcode can be instantly understood and processed by any GS1-enabled system, regardless of location or software.

✅ Improved Traceability

Each GS1 barcode encodes key information such as product ID, batch number, expiration date, and origin. This level of traceability is crucial for recall management, auditing, and compliance for industries like pharmaceuticals, food, or high-value electronics.

✅ Automation Ready

Warehouses and distribution centers equipped with barcode scanners and automated conveyor systems rely heavily on barcode standardization. GS1 barcodes allow seamless integration with warehouse management systems (WMS), reducing manual errors and speeding up throughput.

✅ Better Inventory Accuracy

With case- and pallet-level tracking, businesses can reduce shrinkage, eliminate overstocking, and optimize order fulfillment. When paired with real-time systems, GS1 barcodes provide instant insights into what’s in stock, in transit, or delayed.

How GS1 Barcodes Work at Different Levels

| Level | Barcode Type | Typical Use |

|---|---|---|

| Item/Unit | GTIN (UPC/EAN) | Retail sale or unit-level scanning |

| Case/Carton | GTIN + AI (e.g. lot, expiry) | Master cases in warehouses and shipping |

| Pallet | SSCC (Serialized Shipping Container Code) | Shipping and delivery confirmation |

A pallet label, for example, often includes both a case identifier and an SSCC that enables full tracking from warehouse to retailer dock.

Implementation Tips

How about introducing or upgrading your GS1 tracking system? Here’s what to keep in mind:

- Get Your GS1 Company Prefix

- Apply for a GS1 Company Prefix to generate valid GTINs and SSCCs for your products and logistics units.

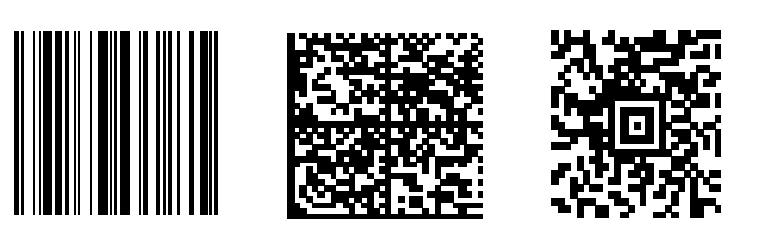

- Use the Right Barcode Type

- Choose 1D (e.g., GS1-128) for traditional scanning or 2D (e.g., DataMatrix) when more data is needed in a compact space.

- Label Placement Matters

- Ensure barcodes are printed in high contrast, scannable locations on pallets and cartons—typically bottom-right corners or adjacent sides.

- Integrate With WMS or ERP Systems

- Sync your barcode data with your internal platforms to fully unlock tracking, alerts, and inventory management benefits.

- Train Staff and Logistics Partners

- Ensure that everyone handling goods—from warehouse workers to delivery teams—understands how to scan and interpret GS1 labels.

Industries That Benefit Most from GS1 Case/Pallet Barcoding

- Retail & FMCG – Streamlined distribution and shelf stocking

- Pharmaceutical – Lot-level traceability and compliance

- Food & Beverage – Cold chain tracking and expiration control

- Electronics – Warranty and component-level inventory tracking

- Logistics & 3PL – Efficient cross-docking and shipment verification

Final Thoughts

GS1 barcoding is not just a tool—it’s a critical logistics infrastructure that ensures accuracy, accountability, and speed across every link in the supply chain. From reducing human error to improving end-to-end visibility, implementing GS1 barcodes at the pallet and case level transforms how businesses move goods.

Whether scaling operations, working with new retail partners, or streamlining your warehouse, PostalParcel can help you integrate GS1 barcoding into your logistics flow.

Need help getting started with GS1 implementation?

Contact us at PostalParcel.com to learn more about our barcode solutions, label printing systems, and warehouse integration services.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua