Using GS1 Labels for Freight and Pallet Tracking

Efficient freight and pallet tracking is essential in today’s supply chain management. Businesses need real-time visibility, standardized identification, and reliable data exchange to meet growing customer demands and regulatory requirements. One of the most powerful tools enabling this level of precision is the GS1-128 barcode, a key component of GS1 labels. These labels are not only widely adopted across logistics networks but are also essential for modern warehouse operations and transportation systems.

What Is a GS1-128 Barcode?

A GS1-128 label is a type of barcode that encodes data in a format based on the Code 128 standard, developed specifically for the GS1 system. Unlike simple barcodes that only store product numbers, it can contain structured information such as:

- Serial numbers

- Batch/lot numbers

- Expiry dates

- Quantity

- Global Trade Item Numbers (GTINs)

- Shipment or pallet identifiers (SSCCs)

This makes the GS1-128 label ideal for freight and pallet tracking, as it provides detailed information about both the product and its logistical context.

Why Use GS1-128 Labels for Freight?

In freight operations, the ability to identify, locate, and monitor shipments accurately is key to reducing errors, delays, and losses. GS1-128 barcodes support this goal by enabling:

- Standardized communication between supply chain partners

- Real-time tracking of shipments and pallets

- Faster check-in/check-out processes in warehouses and distribution centers

- Seamless integration with Warehouse Management Systems (WMS) and Transport Management Systems (TMS)

For example, scanning a GS1 label on a pallet instantly provides data about its contents, origin, destination, and handling requirements. This eliminates the need for manual paperwork and minimizes scanning errors.

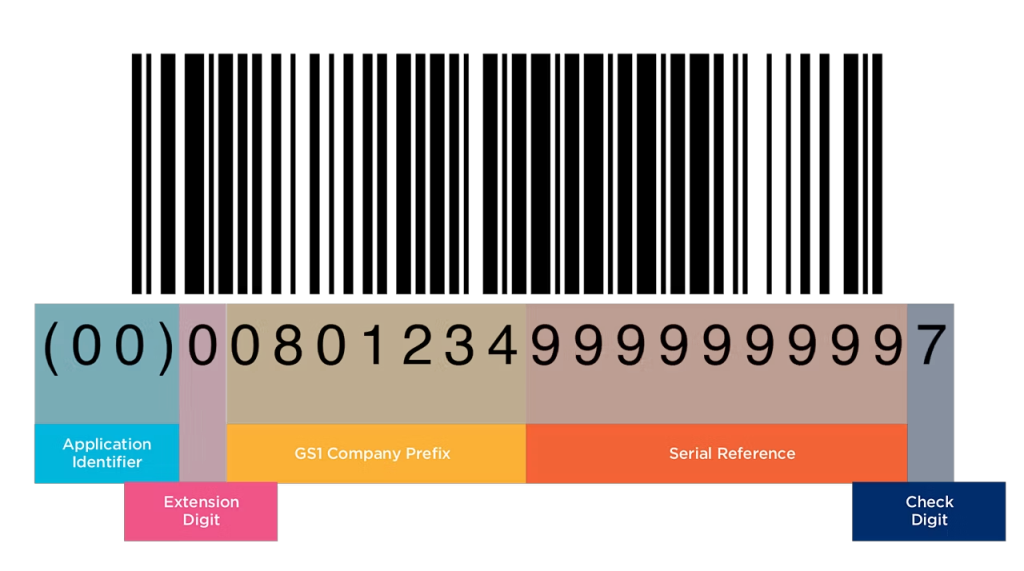

Key Elements in a GS1-128 Freight Label

A typical freight label with a GS1-128 barcode includes several Application Identifiers (AIs), which define the type of data encoded. Common AIs used in freight labels include:

- 00 – SSCC (Serial Shipping Container Code)

- 10 – Batch or Lot number

- 17 – Expiration date

- 37 – Quantity

- 01 – GTIN (Global Trade Item Number)

The SSCC is particularly important. It’s a unique identifier assigned to a specific logistic unit (like a pallet or carton) and is used to track that unit throughout its journey across multiple handlers and locations.

How GS1-128 Enhances Pallet Tracking

Tracking pallets in a warehouse or across shipping terminals requires more than just physical labeling. It requires structured data and reliable identification. GS1-128 barcodes support:

- Aggregation: Linking individual item data to a pallet-level identifier

- Location-based tracking: Mapping the movement of pallets between zones or facilities

- Automated data capture: Scanning pallets at docks or checkpoints without manual input

- Compliance: Meeting retailer or industry-specific labeling standards (such as those from Walmart or pharmaceutical supply chains)

When each pallet carries a GS1 label with a unique SSCC, all stakeholders—from shippers to consignees—can access the same information about that unit. This ensures consistency across systems and provides an auditable tracking history.

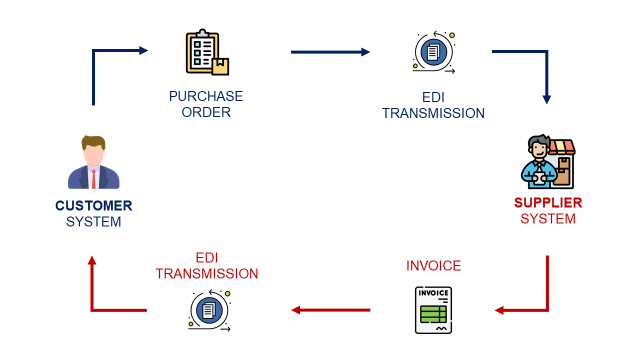

Integration with WMS and EDI Systems

Modern warehouses rely on software systems to manage inventory and logistics data. GS1-128 labels are designed for integration with:

- Warehouse Management Systems (WMS), which use barcodes to receive, store, and ship goods

- Electronic Data Interchange (EDI) systems, which exchange shipping notices, invoices, and inventory updates electronically

By including the SSCC in both the GS1 label and the corresponding EDI message (such as an Advance Shipping Notice or ASN), companies achieve full traceability. This means they can reconcile physical inventory with digital records instantly and with accuracy.

Benefits Across the Supply Chain

Implementing GS1-128 barcodes for freight and pallet tracking offers benefits at every stage of the logistics process:

| Stakeholder | Benefit |

|---|---|

| Shippers | Accurate pallet contents and destinations |

| Carriers | Faster loading/unloading |

| Distributors | Real-time visibility and inventory control |

| Retailers | Compliance with inbound requirements |

| Regulators | Audit-ready traceability |

This level of transparency leads to fewer shipment disputes, less manual work, and higher customer satisfaction.

Best Practices for Implementation

To make the most of GS1-128 labels, consider the following steps:

- Use authorized GS1 Application Identifiers

Follow the GS1 General Specifications to ensure label consistency. - Maintain printer quality

Low-quality printing can lead to unreadable barcodes. Use thermal transfer printers and high-contrast labels. - Test barcode readability

Use scanners or mobile devices to validate that barcodes are scannable under warehouse and transportation conditions. - Align with trading partners

Confirm that your label formats and data structures meet the expectations of your logistics partners and customers.

Conclusion

The GS1-128 barcode has become a cornerstone of modern freight and pallet tracking. It allows companies to move goods efficiently, share data reliably, and comply with global standards. By implementing GS1 labels across their operations, businesses improve traceability, reduce errors, and build a more responsive and integrated supply chain.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua