Top Challenges in Inventory and Order Management

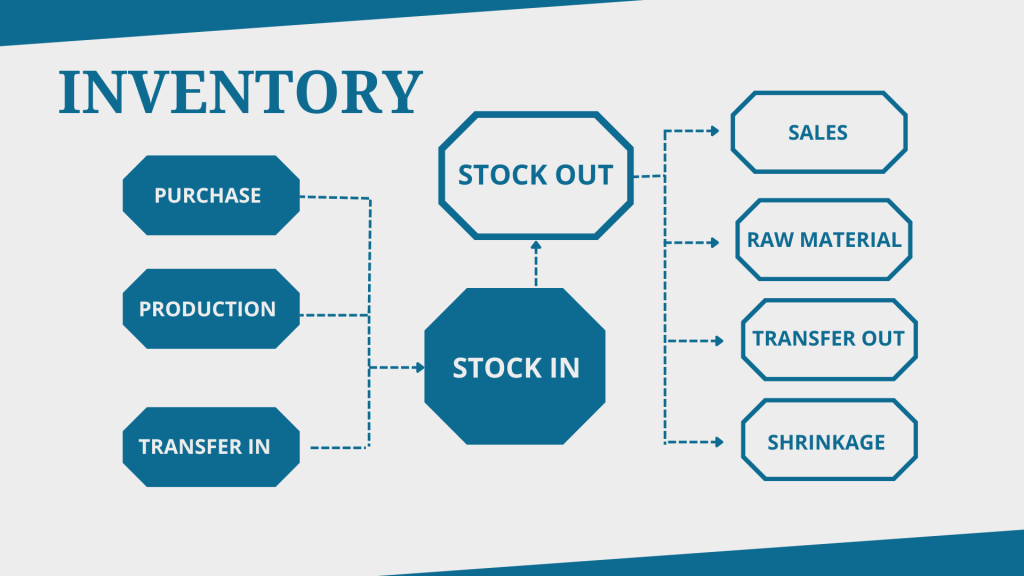

Efficient inventory and order management is the backbone of a successful e-commerce or retail operation. However, as businesses scale and consumer expectations evolve, managing stock levels, tracking orders, and ensuring timely fulfillment becomes increasingly complex. In this article, we’ll explore the most pressing challenges in inventory and order management and provide actionable solutions to overcome them.

1. Lack of Real-Time Inventory Visibility

The Challenge:

One of the most common issues businesses face is the inability to view real-time inventory across multiple channels or warehouses. Without centralized visibility, stockouts and overstocking become frequent, leading to lost sales or increased holding costs.

The Solution:

Implement a cloud-based management system that synchronizes stock data across all sales channels, warehouses, and fulfillment centers in real time. Platforms like NetSuite, TradeGecko, or Cin7 allow businesses to track product movements and set automatic reorder points, ensuring optimal supply levels and more accurate demand forecasting.

2. Manual and Error-Prone Processes

The Challenge:

Many small and mid-sized businesses still rely on spreadsheets or manual entry systems to manage inventory and orders. This approach is time-consuming and prone to human error—such as incorrect stock counts, delayed order updates, or double-shipping.

The Solution:

Automate your workflows using integrated software solutions. A platform that unifies inventory, order processing, and shipping—like ShipStation or Zoho Inventory—can eliminate manual entry, reduce human error, and accelerate operations. Barcode scanning and RFID tracking can further enhance accuracy and speed.

3. Inefficient Order Fulfillment

The Challenge:

Order delays, picking and packing mistakes, or missed shipments are all signs of fulfillment inefficiencies. These issues can frustrate customers and increase return rates, harming your reputation and bottom line.

The Solution:

Adopt a smart order routing system that chooses the best fulfillment center based on location, stock availability, and shipping speed. Standardizing your picking and packing processes with digital checklists or warehouse management systems (WMS) can also reduce errors. For growing businesses, outsourcing to a trusted 3PL (Third-Party Logistics provider) like ShipBob or postalparcel can drastically improve fulfillment efficiency.

4. Demand Forecasting Inaccuracies

The Challenge:

Overestimating demand leads to excessive inventory, while underestimating it causes stockouts. Poor forecasting can result in financial loss and disrupt cash flow.

The Solution:

Use predictive analytics and historical sales data to refine your forecasting model. Integrating inventory software with machine learning or AI-based forecasting tools can help you better anticipate market trends, seasonal spikes, and product lifecycles. Regularly reviewing trends and collaborating with your marketing and sales teams can further improve forecast accuracy.

5. Returns and Reverse Logistics Complexity

The Challenge:

Handling returns effectively is a critical part of order management, especially in e-commerce. A disorganized return process can tie up inventory, create customer dissatisfaction, and inflate operational costs.

The Solution:

Implement a clear, automated return workflow that integrates with your system. Returned items should be assessed quickly for restocking, repair, or disposal. Offering prepaid return labels, tracking return status, and notifying customers of refund timelines also improves the overall customer experience.

6. Scaling Across Multiple Sales Channels

The Challenge:

As brands expand to new marketplaces—like Amazon, eBay, or international websites—the complexity of inventory tracking and order consolidation increases.

The Solution:

Use multichannel platforms like Linnworks or Sellbrite that integrate with all your sales channels. These tools allow centralized tracking, synchronized inventory levels, and consolidated order dashboards, making it easier to manage multiple storefronts without losing control.

7. Lack of Integration Between Systems

The Challenge:

When inventory, order processing, accounting, and CRM tools are disconnected, data silos are created. This leads to delays, miscommunication, and inaccurate reporting.

The Solution:

Choose solutions that offer API integration or adopt an all-in-one ERP system. Integration ensures that your sales data flows seamlessly into your inventory and finance systems, providing a unified view of business performance. If your business uses WooCommerce, integrating with inventory tools like PostalParcel’s plugin can streamline logistics from your e-commerce backend to fulfillment.

Conclusion

The challenges are inevitable, but they can be solved with the right combination of technology, automation, and process optimization. Whether you’re a growing DTC brand or a global fulfillment provider, investing in a smart, integrated system will not only improve operational efficiency but also enhance customer satisfaction and profitability.

At PostalParcel, we specialize in providing cross-border logistics and smart order fulfillment solutions tailored to your business needs. From inventory sync to end-to-end delivery, our platform ensures you stay in control—no matter where your orders are coming from.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua