Supply Chain Visibility to Prevent Disruptions

In a world defined by uncertainty, complexity, and rapid change, businesses can no longer afford to operate their supply chains in the dark. From pandemic-induced shutdowns and port congestion to raw material shortages and geopolitical instability, logistics disruptions have become the norm, not the exception. To navigate this landscape, organizations need more than just flexibility—they need visibility.

Supply chain visibility (SCV) has emerged as a vital tool for preventing, mitigating, and even capitalizing on disruptions. It offers real-time insight into every stage of the supply chain, enabling faster decision-making, greater efficiency, and higher resilience.

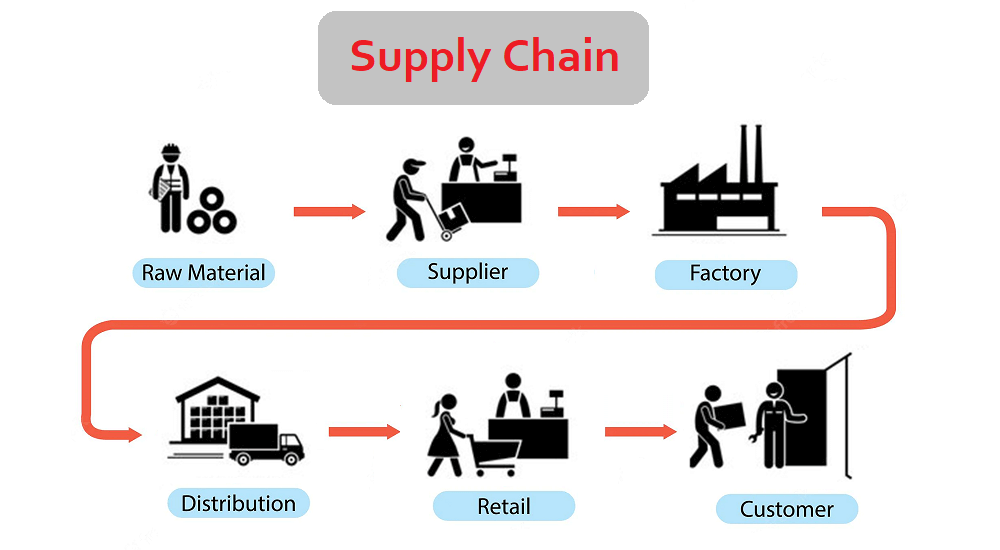

What is Supply Chain Visibility?

At its core, supply chain visibility is the ability to track, monitor, and manage every component of the supply chain across multiple tiers and geographies in real time. This includes not just the location of goods in transit, but also inventory levels, supplier performance, manufacturing status, and even environmental or geopolitical conditions that could affect operations.

Modern SCV goes beyond simple shipment tracking. It integrates data from IoT devices, enterprise resource planning (ERP) systems, warehouse management systems (WMS), and third-party logistics (3PL) providers into a unified, dynamic view of the entire network.

Why Supply Chain Visibility Is Essential to Prevent Disruptions

Disruptions in logistics don’t always arrive with advance warning. However, organizations that have invested in visibility platforms can identify patterns and potential breakdowns before they escalate into costly crises. Here are a few key ways SCV helps prevent disruptions:

1. Early Warning and Proactive Response

Visibility tools allow businesses to receive real-time alerts when anomalies occur—such as delayed shipments, unplanned downtime, or supplier non-compliance. By detecting these issues early, teams can reroute shipments, activate alternative suppliers, or adjust production plans in time to avoid delays.

2. Inventory Optimization

Too much inventory leads to high carrying costs; too little results in stockouts and lost sales. With real-time data on demand trends, warehouse status, and transit times, businesses can optimize inventory across locations and maintain just-in-time levels with greater confidence.

3. Enhanced Collaboration Across the Ecosystem

Disruptions often worsen due to poor communication. SCV tools foster data transparency across suppliers, carriers, warehouses, and internal teams, reducing silos and enabling faster coordinated responses.

4. Improved Customer Experience

Customers today expect transparency. SCV enables accurate delivery tracking, proactive notifications, and realistic lead times, which build trust and satisfaction—even when delays are unavoidable.

5. Compliance and Risk Mitigation

Some industries—such as pharmaceuticals, food and beverage, and automotive—face strict compliance requirements. Visibility ensures traceability for every component or ingredient, aiding in recalls, audits, and sustainability reporting.

Key Features of a Modern Visibility Platform

To effectively prevent and manage disruptions, a visibility solution should include:

- End-to-end tracking: From raw materials to final delivery

- Real-time data integration: IoT sensors, GPS, EDI, and APIs

- Predictive analytics and AI: To forecast potential delays or bottlenecks

- Customizable dashboards: For different roles across the supply chain

- Automated alerts and exceptions management

- Collaboration tools: To share updates and documentation with partners

Technologies Powering Supply Chain Visibility

Internet of Things (IoT)

IoT sensors embedded in containers, vehicles, and warehouses transmit live data on temperature, location, humidity, and shock, enabling condition-based monitoring—critical for perishables and high-value goods.

Artificial Intelligence and Machine Learning

AI helps interpret vast datasets to identify anomalies, predict outcomes, and recommend corrective actions. Machine learning models improve over time, enhancing forecasting and risk mitigation capabilities.

Blockchain

For industries where traceability is essential, blockchain provides an immutable ledger of product movement and ownership. It enhances trust, transparency, and compliance across multiple stakeholders.

Cloud-Based Platforms

Cloud-based SCV systems provide scalability, speed of deployment, and global accessibility. They eliminate the need for complex infrastructure and enable real-time updates from anywhere in the world.

A Real-World Example: How Visibility Averted a Crisis

Consider a multinational retailer relying on Tier 2 suppliers from Southeast Asia. Using an advanced visibility platform, the company received an alert about a political protest affecting a supplier’s local port. With real-time insight into inventory levels and in-transit goods, they swiftly rerouted critical shipments to an alternative port and coordinated with 3PL partners to avoid disruption.

Without such visibility, the delay could have resulted in empty shelves during a peak shopping season, lost revenue, and a tarnished brand reputation.

Best Practices for Implementing Visibility Solutions

Implementing a visibility system is not just a technological upgrade—it’s an operational transformation. Here’s how to get started:

- Map your supply chain: Identify all players, touchpoints, and data gaps

- Select flexible platforms: Choose solutions that integrate with existing systems (ERP, WMS, etc.)

- Focus on data accuracy: Poor-quality data undermines visibility

- Establish governance: Define who owns which data and how it’s maintained

- Train your teams: Empower users to interpret insights and act on alerts

- Foster supplier cooperation: Visibility requires collaboration, not just technology

The Strategic Value of Visibility

Beyond avoiding disruptions, supply chain visibility can unlock strategic advantages. It helps reduce costs, shorten lead times, improve ESG (environmental, social, and governance) compliance, and drive smarter sourcing decisions. As digital transformation accelerates, visibility will become a cornerstone of supply chain excellence.

Conclusion

Disruptions in logistics are no longer “if,” but “when.” The businesses that thrive are not those that avoid all problems, but those that see them coming and act quickly. Supply chain visibility provides that foresight.

By adopting real-time tracking, predictive analytics, and collaborative tools, companies can build resilient, responsive, and agile supply chains—turning visibility into a competitive edge in an unpredictable world.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua