TMS in Cold Chain Logistics: Ensuring Temperature-Controlled Transport

The global demand for temperature-sensitive goods—such as pharmaceuticals, fresh produce, vaccines, and biologics—has grown exponentially. However, maintaining product integrity during transport remains one of the cold chain’s biggest challenges. A slight deviation from the required temperature range can lead to product spoilage, loss of revenue, and safety risks for end consumers.

This is where a Transportation Management System (TMS) plays a critical role. In cold chain logistics, a modern TMS is more than a route planner—it is a real-time command center that safeguards the entire delivery cycle.

This article explores how TMS technology transforms cold chain logistics by offering visibility, control, and Compliance throughout temperature-controlled transport.

What Is Cold Chain Logistics?

Cold chain logistics refers to transporting perishable or temperature-sensitive goods under regulated conditions. This includes strict temperature, humidity, and handling guidelines from origin to destination.

Industries relying on cold chain logistics include:

- Pharmaceuticals (vaccines, insulin, biologics)

- Food & Beverage (dairy, seafood, frozen meals)

- Agriculture (fresh produce, flowers)

- Chemical & Biotech (lab samples, reagents)

Maintaining an unbroken cold chain is vital. Even a brief exposure to improper conditions can render a product unusable or unsafe.

Why TMS Is Essential for Cold Chain Operations

Traditional cold chain methods rely on manual processes and reactive responses to problems. A TMS empowers shippers with proactive, data-driven control, helping them achieve:

- Real-time monitoring

- Predictive problem detection

- Automated Compliance

- Efficient route planning

Below are the key ways a TMS enhances temperature-controlled logistics:

1. Real-Time Temperature Monitoring

Integrated IoT sensors and data loggers can feed real-time temperature data into the TMS dashboard. Logistics managers can:

- Track temperature fluctuations

- Receive automated alerts for deviations

- Take corrective action before product quality is compromised

This level of visibility helps avoid spoilage and regulatory violations.

2. Route Optimization for Time-Sensitive Deliveries

Perishable goods often have strict time windows. A TMS calculates the most efficient routes based on:

- Delivery deadlines

- Real-time traffic

- Weather conditions

- Road restrictions

This ensures goods arrive faster and safer while reducing fuel consumption and risk of delay.

3. Carrier and Equipment Matching

Cold chain transport isn’t just about trucks but the right trucks with specialized equipment. A TMS helps match loads with carriers that offer:

- Refrigerated trailers

- Pre-set temperature controls

- Certifications for temperature-sensitive handling

This minimizes handling errors and supports consistent transport conditions.

4. Automated Compliance & Documentation

Cold chain logistics is highly regulated. A TMS simplifies Compliance with:

- Electronic records of temperature data

- GPS tracking logs

- Electronic Proof of Delivery (ePOD)

- Audit-ready reporting

This helps businesses comply with standards like FDA 21 CFR Part 11, GDP (Good Distribution Practices), and WHO cold chain guidelines.

5. Inventory and Shipment Visibility

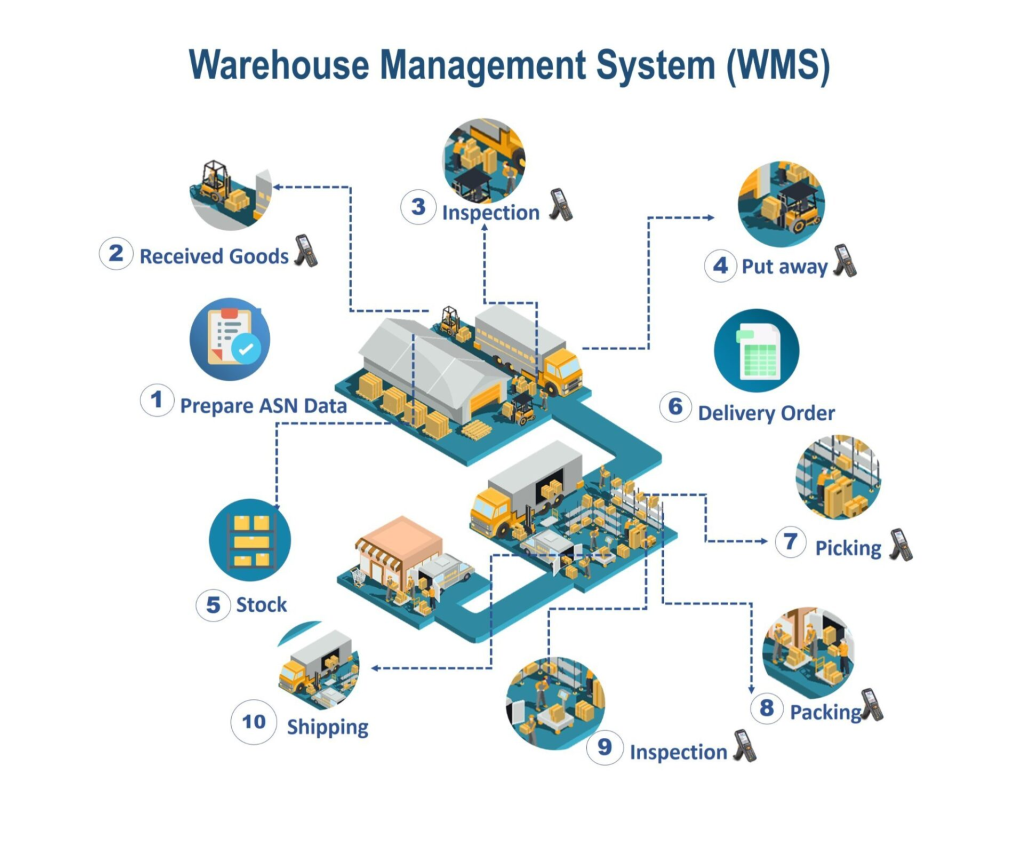

By integrating with Warehouse Management Systems (WMS) and ERP platforms, a TMS offers end-to-end supply chain visibility:

- See when a shipment leaves cold storage

- Monitor location, temperature, and ETA in real-time

- Provide customers with live tracking updates

This transparency increases trust and allows better coordination across stakeholders.

Benefits of Using a TMS in Cold Chain Logistics

| Benefit | Impact |

|---|---|

| Temperature Integrity | Prevent spoilage and quality degradation |

| Regulatory Compliance | Stay audit-ready and avoid legal penalties |

| Operational Efficiency | Fewer delays, lower costs, optimized loads |

| Risk Reduction | Early detection of anomalies via alerts |

| Customer Satisfaction | Transparent tracking and reliable delivery windows |

Who Should Use TMS for Cold Chain?

- Pharmaceutical manufacturers shipping high-value medicine

- Food exporters/importers dealing with multi-regional distribution

- 3PLs handling temperature-sensitive contracts

- Agricultural cooperatives delivering fresh produce to retailers

- Hospitals and labs transporting diagnostics and samples

How PostalParcel Supports Cold Chain Success

At PostalParcel, we understand that cold chain delivery requires precision, speed, and real-time responsiveness. Our logistics solutions integrate with leading TMS platforms to offer:

- Real-time shipment monitoring

- Intelligent routing for perishable cargo

- ePOD and digital record-keeping

- Smart alerts for temperature excursions

- Cold chain performance analytics

Whether you’re managing vaccine deliveries or daily fresh food routes, PostalParcel ensures your cold chain remains unbroken from warehouse to doorstep.

Final Thoughts

Cold chain logistics is no longer just a back-end function—it’s a frontline responsibility. Leveraging a robust TMS provides the tools and data required to deliver sensitive goods safely, efficiently, and fully compliant with industry standards.

As demand for temperature-controlled delivery grows, companies prioritizing cold chain integrity will stand out.

Are you looking to modernize your cold chain operations? Contact PostalParcel and discover how our intelligent TMS integrations can elevate your delivery standards.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua

[…] b. Cold Chain Logistics […]

[…] fulfillment is essential to meeting customer expectations and ensuring the smooth operation of global businesses. By leveraging advanced logistics networks, intelligent order allocation, and automation tools, […]

[…] Partners and intermediaries across the logistics chain […]

[…] Shipping temperature-sensitive goods requires precision and constant monitoring. Products need to be transported under optimal conditions, from pharmaceuticals to perishable food and high-end electronics, to avoid damage. PostalParcel helps businesses track these shipments in real time, offering enhanced visibility, proactive alerts, and optimized delivery solutions to ensure safe and efficient deliveries. […]