From Warehouse to Delivery: IoT and RFID in Ultimate End-to-End Tracking

Achieving seamless visibility from warehouse storage to final delivery is a top logistics and supply chain operations priority. Customers expect real-time updates on order status, while companies seek to minimize loss, improve efficiency, and ensure product quality throughout the journey. IoT (Internet of Things) and RFID (Radio Frequency Identification) technologies are revolutionizing end-to-end tracking by closing visibility gaps across every stage.

What is RFID and How Does it Work?

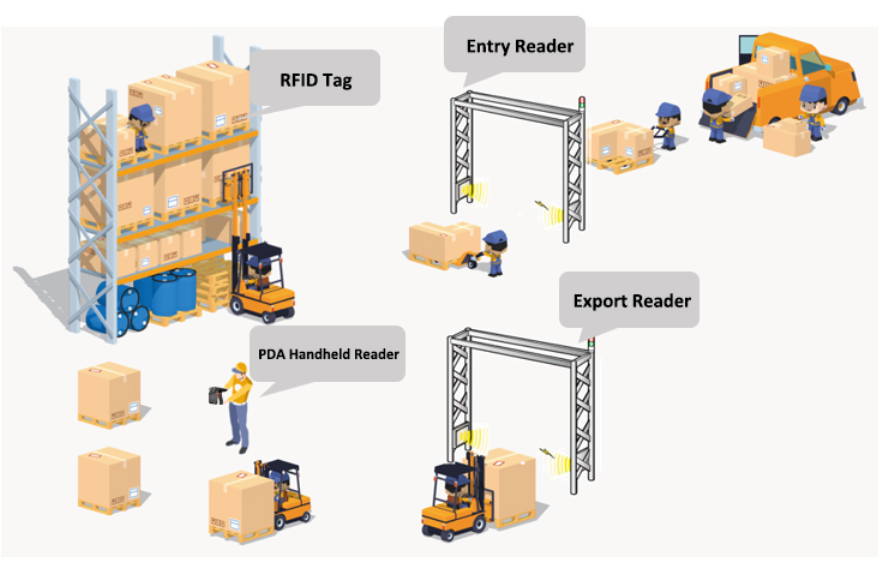

RFID uses electromagnetic fields to identify and track tags attached to objects automatically. These tags contain electronically stored information that RFID readers can read within a specific range.

Key Features:

- No direct line-of-sight is needed, unlike traditional barcodes

- Faster scanning of multiple items simultaneously

- Data storage for product details, manufacturing data, and batch numbers

RFID systems are widely used in warehouses to track inventory movement, reduce manual scanning errors, and improve stock accuracy.

How IoT Enhances RFID Capabilities

While RFID provides identification and static tracking, IoT sensors deliver dynamic, real-time monitoring of environmental conditions, location, and asset status.

Combining IoT and RFID enables:

- Location Tracking: RFID tags identify and verify each item within the warehouse or distribution center, ensuring accurate inventory records and efficient picking processes. During transit, IoT GPS devices track the real-time location of shipments, providing continuous updates on their journey. This end-to-end visibility allows logistics teams to optimize routing, proactively manage delays, and provide customers with precise estimated arrival times, enhancing service reliability.

- Condition Monitoring: IoT sensors continuously monitor critical environmental factors such as temperature, humidity, and vibration levels to maintain product quality throughout storage and transportation. This is particularly vital in cold chain logistics for perishable goods, pharmaceuticals, and temperature-sensitive products. If any parameter deviates from the acceptable range, automated alerts are triggered instantly, enabling corrective action to protect product integrity and comply with safety standards.

- Process Automation: Automatic data collection through integrated RFID and IoT systems eliminates the need for manual scanning or entry at multiple stages of the supply chain. This not only reduces human error but also accelerates processes such as inventory updates, picking, packing, and shipping documentation. Automation streamlines operations, enhances workforce productivity, and allows staff to focus on higher-value tasks.

- Predictive Analytics: Continuous data flow from IoT sensors and RFID systems generates valuable insights into operational patterns, identifying potential bottlenecks, recurring delays, or areas prone to damage risks. By analyzing these data trends, logistics companies can implement proactive measures such as route adjustments, equipment maintenance scheduling, or packaging improvements, ultimately enhancing efficiency, reducing costs, and improving customer satisfaction.

From Warehouse to Delivery: The Full Journey

- Warehouse Storage: Products tagged with RFID are logged into inventory systems instantly upon arrival, allowing for seamless and accurate stock updates without manual data entry. IoT-enabled shelves or pallets continuously track storage conditions such as temperature, humidity, and light exposure to maintain quality standards, ensuring that sensitive products remain in optimal condition throughout their storage period and reducing the risk of spoilage or damage.

- Picking and Packing: RFID readers quickly identify and verify the correct SKUs from warehouse shelves, reducing picking errors and improving order accuracy. Meanwhile, IoT scanners confirm package weight and dimensions in real-time, ensuring that each parcel is packed correctly and shipping costs are optimized based on accurate volumetric data, which enhances overall operational efficiency.

- Outbound Logistics: As items leave the warehouse, RFID gates record departure. GPS-enabled IoT devices track truck location and estimated arrival times.

- Delivery and Handover: Last-mile delivery status is updated in real-time via IoT connectivity, enhancing customer transparency and reducing failed deliveries.

Real-World Application Example

Platforms like PostalParcel integrate IoT and RFID technologies to provide comprehensive logistics tracking for cross-border inventory and order management.

Implementation Highlights:

- Intelligent inventory management with RFID tagging integrated into warehouse systems for precise stock control

- Temperature monitoring of sensitive shipments using IoT sensors, with automated alerts for deviations

- GPS-enabled IoT devices offering accurate ETAs, enhancing delivery reliability

- RFID checkpoints combined with IoT-based security monitoring to detect unauthorized movements within facilities

These applications reflect how logistics service providers adopt technology to build more flexible, data-driven fulfillment solutions beyond traditional warehouse management systems.

Challenges of IoT and RFID Integration

Despite the advantages, deploying IoT and RFID at scale involves:

- Infrastructure investments for readers, sensors, and connectivity

- Complex data management, integrating large data volumes into existing systems

- Standardization Challenges: Different vendors use varying protocols and data formats, creating integration issues. Companies need extra tools or customization to ensure all devices work seamlessly together.

- Privacy Considerations: Real-time delivery tracking collects sensitive customer data. Strong encryption, strict access controls, and clear privacy policies are essential to protect data and maintain trust.

The Road Ahead

Combining IoT and RFID represents the next evolution in end-to-end logistics tracking. As customer expectations continue to rise, companies incorporating these technologies gain opportunities to improve operational efficiency, ensure product safety, and strengthen customer trust.

Conclusion

IoT and RFID reshape logistics from warehouse to delivery by enabling real-time visibility, condition monitoring, and automated tracking. By integrating these technologies thoughtfully, businesses can build more adaptive, reliable, and efficient supply chains ready for the demands of modern commerce.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua