Tracking Technologies in Logistics: From RFID to GPS and Beyond

In today’s fast-paced and customer-centric logistics environment, tracking technologies ensure transparency, efficiency, and reliability across supply chains. Logistics tracking technologies have evolved significantly from the early adoption of barcodes to advanced RFID systems and real-time GPS tracking. This article explores these technologies, their benefits, limitations, and emerging trends shaping the future of logistics.

1. The Importance of Tracking in Logistics

Tracking technologies enable logistics companies to:

- Monitor goods in transit and storage

- Optimise routes and delivery schedules

- Improve inventory management accuracy

- Enhance customer satisfaction with real-time updates

- Reduce losses, theft, and operational errors

As global trade grows and customer expectations for visibility rise, advanced tracking systems become essential for competitive logistics operations.

2. Barcodes: The Foundation of Modern Tracking

Barcodes revolutionised logistics by allowing rapid data capture of product IDs, shipment details, and warehouse locations. They remain widely used due to their low cost and simplicity. However, barcodes have limitations:

- Line-of-sight requirement: Each item must be scanned individually.

- Limited data storage: Only encodes static information such as SKU or product code.

- Prone to damage: Scratches or poor printing can cause scanning errors.

Despite these limitations, barcodes remain fundamental for basic inventory tracking, especially for small businesses with simple logistics needs.

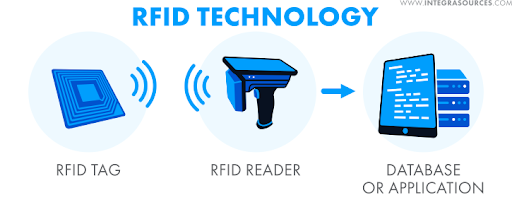

3. RFID: Enhancing Efficiency and Automation

Radio Frequency Identification (RFID) overcomes many barcode limitations by using radio waves to transmit data from tags to readers without line-of-sight scanning.

Benefits of RFID:

- Bulk scanning: Multiple items can be scanned simultaneously, reducing handling time.

- Improved accuracy: Reduces manual scanning errors and improves inventory visibility.

- Data flexibility: Tags can store dynamic data such as manufacturing dates, batch numbers, or temperature history.

Limitations:

- Cost: Higher than barcodes, especially for active RFID tags with batteries.

- Interference issues: Metal and liquid products can affect signal strength.

- Infrastructure requirements: Requires investment in RFID readers and integration systems.

Despite these challenges, RFID is increasingly adopted in warehouses, retail distribution, and cold chain management to automate stocktaking and improve supply chain visibility.

4. GPS Tracking: Real-Time Shipment Visibility

Global Positioning System (GPS) technology has transformed fleet and shipment tracking by providing real-time location data.

Benefits of GPS tracking:

- Real-time updates: Customers and managers know exactly where shipments are.

- Route optimisation: Helps drivers avoid traffic and reduce delivery times.

- Enhanced security: Alerts for route deviations reduce theft risks.

- Performance monitoring: Tracks driver behaviour and vehicle performance for maintenance planning.

Limitations:

- Network dependency: Requires reliable internet or satellite connectivity.

- Privacy concerns: Continuous tracking raises driver privacy issues.

- Cost: Requires GPS-enabled devices and data plans for tracking.

GPS remains essential for long-haul transport, last-mile delivery, and third-party logistics providers aiming to offer reliable estimated arrival times (ETAs).

5. Beyond RFID and GPS: Emerging Tracking Technologies

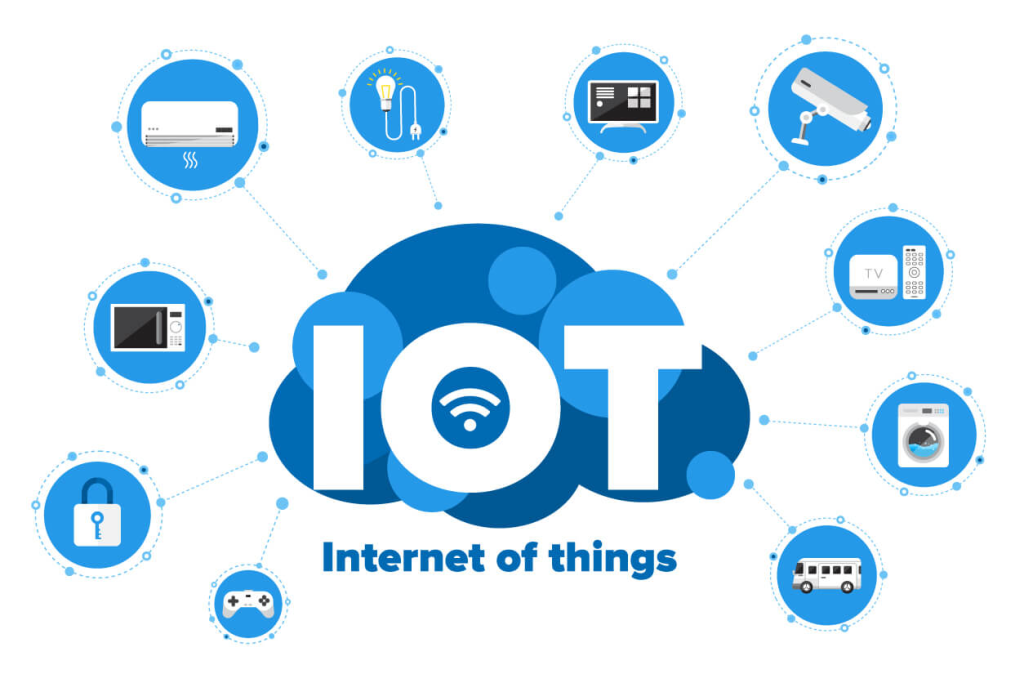

a) Internet of Things (IoT)

IoT devices integrate sensors, connectivity, and data analytics to provide advanced tracking capabilities. For example, temperature and humidity sensors ensure cold chain integrity for food and pharmaceutical shipments. IoT-enabled pallets and containers continuously monitor goods’ conditions and locations throughout transit.

b) Bluetooth Low Energy (BLE) Beacons

BLE beacons provide indoor tracking capabilities where GPS signals are weak, such as within warehouses or distribution centres. They help improve inventory location accuracy and streamline picking operations.

c) Blockchain for Tracking Data Integrity

Blockchain does not track items physically but provides a secure, tamper-proof ledger of tracking data. It ensures data transparency and integrity across multiple supply chain partners, which is ideal for food safety, pharmaceuticals, and international trade compliance.

d) AI and Predictive Analytics

Artificial intelligence analyses tracking data to predict delivery times, detect potential delays, and recommend real-time route adjustments. AI also enhances asset utilisation by forecasting demand and optimising fleet deployment.

PostalParcel Case Example

PostalParcel, a flexible logistics platform, integrates GPS tracking for SMEs and cross-border sellers to improve shipment visibility and customer service. For example, when a seller ships high-value electronics internationally, PostalParcel’s platform combines GPS data with carrier tracking updates in one dashboard. This allows customer service teams to proactively inform buyers of any delays or customs clearance status. As a result, sellers using PostalParcel have reported up to 30% fewer “Where is my order?” inquiries and higher customer satisfaction ratings due to transparent, real-time shipment updates.

6. Challenges in Implementing Advanced Tracking Technologies

Despite their benefits, adopting advanced tracking technologies comes with challenges:

- Integration complexity: Requires seamless integration with existing WMS, TMS, and ERP systems.

- Data overload: Large volumes of tracking data need robust analytics to extract actionable insights.

- Cost considerations: SMEs may find the upfront investment in RFID or IoT infrastructure challenging without clear ROI planning.

- Cybersecurity risks: Increased connectivity creates vulnerabilities if not protected with strong security measures.

7. The Future of Tracking Technologies in Logistics

Looking ahead, tracking technologies will become more interconnected and intelligent. The combination of IoT, AI, and blockchain will enable:

- End-to-end real-time visibility: From supplier warehouses to customers’ doors.

- Automated decision-making: AI-driven route planning and stock replenishment.

- Sustainable logistics: Improved tracking leads to optimised routes, reducing fuel consumption and emissions.

Conclusion

From barcodes to RFID and GPS, tracking technologies have continually advanced to meet the demands of a complex logistics landscape. Emerging solutions like IoT, blockchain, and AI are paving the way for smarter, more transparent, and efficient supply chains. Logistics companies that embrace these innovations will improve operational performance, build customer trust, and stay competitive in the rapidly evolving digital economy.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua