How IoT Improves Inventory Accuracy in Logistics Warehousing

Inventory accuracy is the foundation of efficient logistics and warehousing operations. Errors in inventory data lead to stockouts, overstocking, wasted storage space, and lost sales opportunities. Maintaining real-time inventory visibility has become a strategic imperative. The Internet of Things (IoT) transforms traditional warehousing by enabling automated, precise, and data-driven inventory management.

1. What is IoT in the context of warehousing?

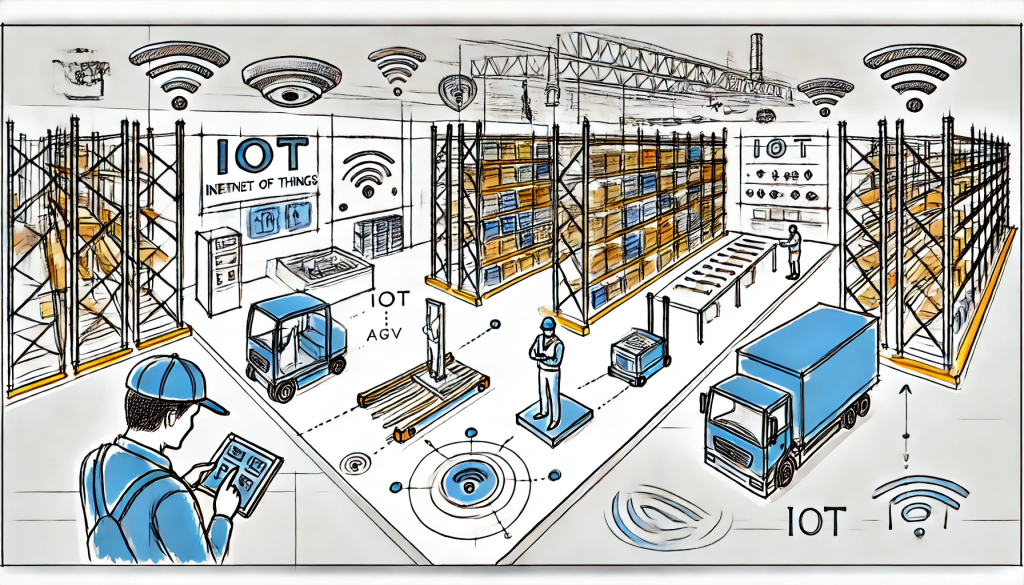

The Internet of Things refers to a network of physical devices embedded with sensors, software, and connectivity capabilities to collect and exchange data. In warehousing, IoT connects devices such as RFID readers, smart shelves, pallet trackers, environmental sensors, conveyor systems, and automated guided vehicles (AGVs). These devices create an integrated digital ecosystem that feeds live operational data into Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) platforms.

Unlike traditional systems where data is updated manually, IoT devices continuously send information about item locations, quantities, movements, and conditions. This builds a dynamic digital twin of the warehouse environment, allowing managers to make informed decisions in real-time.

2. How IoT enhances inventory accuracy

a. Real-time item tracking

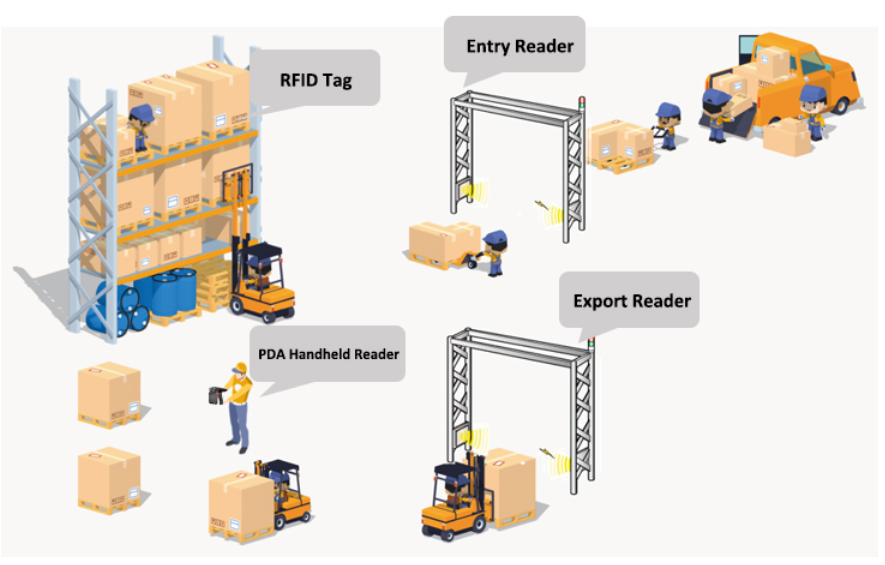

Traditional inventory tracking relies heavily on manual barcode scanning. Although barcode scanning is faster than paper logs, it still requires line-of-sight, physical scanning, and human intervention, introducing the potential for errors. IoT-enabled RFID systems solve these problems. RFID tags attached to items or pallets can be scanned automatically by readers without direct line-of-sight.

When a pallet enters or exits a warehouse zone, RFID gates capture its movement instantly, updating inventory records within the WMS. This continuous tracking significantly reduces the chances of misplaced, unrecorded, or double-counted items and ensures that stock data matches physical reality at any given moment.

b. Automated stock level updates

IoT sensors embedded on shelves can detect the presence or absence of items, updating stock levels automatically in the WMS. Smart shelves use weight sensors, light sensors, or optical scanners to sense changes in inventory levels as items are picked or restocked. This eliminates manual counting and periodic audits, prone to omissions or incorrect data entry.

With automated updates, warehouse staff focus on value-added tasks such as order picking, packing, kitting, and quality control instead of spending hours on routine stock checking.

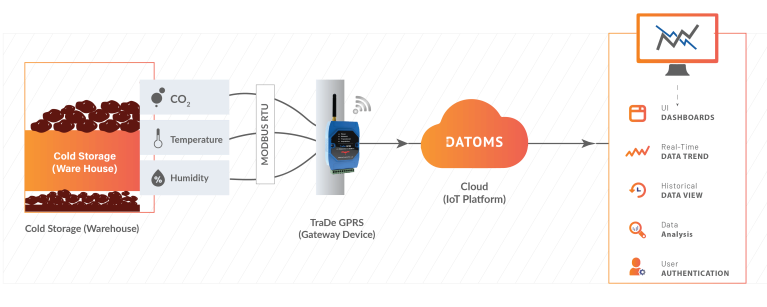

c. Condition monitoring for sensitive inventory

Inventory accuracy goes beyond quantity. In sectors such as pharmaceuticals, food logistics, and cold chain operations, it is crucial to maintain environmental conditions to preserve inventory quality. IoT temperature and humidity sensors continuously monitor storage conditions. If readings exceed predefined thresholds, alerts are triggered to warehouse supervisors, enabling immediate corrective action.

Such condition monitoring ensures compliance with safety standards and prevents wastage from undetected spoilage or temperature excursions, which can otherwise result in lost revenue, penalties, and reputational damage.

d. Faster and more accurate audits

Traditional inventory audits involve suspending operations, manually counting items, and reconciling with recorded data. This approach leads to downtime and operational delays. IoT systems enable continuous cycle counting by dynamically tracking item movement and status. Warehouse managers can schedule rolling audits without halting daily operations, maintaining high inventory accuracy with minimal disruption.

e. Location-based efficiency improvements

Knowing the exact location of items in real-time makes warehouse layout optimization possible. Frequently picked items can be positioned closer to packing stations, while slow-moving items can be moved to higher racks or remote storage areas, improving overall operational efficiency.

3. IoT-enabled predictive analytics for inventory planning

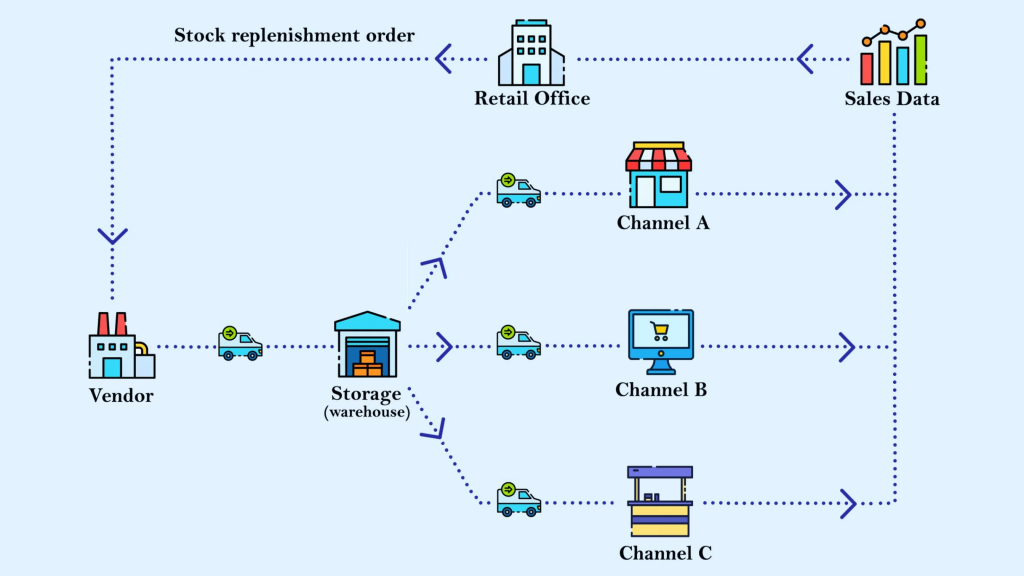

Beyond ensuring accuracy, IoT data feeds into predictive analytics tools. Item movement data reveals demand patterns, peak order periods, and seasonal trends. By analyzing these patterns, warehouse teams optimize:

- Replenishment schedules, preventing stockouts during peak demand

- Storage layouts, reducing travel time during picking

- Workforce allocation, aligning staff with expected workloads

Businesses reduce stockouts and avoid excess inventory, directly improving working capital efficiency. Data-driven forecasting also enhances supplier negotiations and procurement planning.

4. Integration with logistics platforms for seamless operations

Many logistics platforms integrate IoT functionality into their solutions to create end-to-end visibility. PostalParcel, for example, offers flexible fulfillment and inventory management tools that leverage IoT data to enhance operational precision. Its platform integrates inventory data, order tracking, route optimization, and last-mile delivery, creating a unified operational view. While warehousing is only one part of the logistics cycle, integrating IoT insights ensures orders are processed faster, inventory remains updated accurately, and customers receive timely delivery notifications.

Such integration allows businesses to respond quickly to demand fluctuations, process returns efficiently, and maintain service reliability standards in competitive e-commerce and retail environments.

5. Benefits of IoT for warehousing inventory accuracy

- Improved data reliability: Automated data capture eliminates manual entry errors.

- Reduced operational costs: Less time spent on manual checks results in lower labor costs.

- Enhanced security: Real-time tracking reduces theft and misplacement risks.

- Better resource allocation: Accurate data enables optimal space utilization and staff planning.

- Regulatory compliance: Continuous monitoring maintains storage standards for temperature-sensitive goods.

- Increased customer satisfaction: Accurate inventory ensures products are in stock and shipped promptly.

6. Challenges to consider

While IoT offers transformative benefits, implementation must address:

- Integration complexity: Ensuring compatibility with existing WMS and ERP systems requires strategic planning.

- Cybersecurity risks: Sensor networks and connected devices must be secured to prevent data breaches or unauthorized access.

- Initial investment: Hardware, software, and staff training costs can be significant, though the return on investment typically materializes through increased efficiency, accuracy, and reduced wastage.

- Maintenance needs: IoT devices require calibration, firmware updates, and periodic replacements to maintain performance.

7. Emerging trends in IoT-enabled warehousing

IoT is evolving alongside AI, robotics, and edge computing. Predictive maintenance of warehouse equipment based on IoT sensor data reduces unplanned downtime. Automated order picking with AGVs and robotic arms improves throughput. Drone-based inventory scanning is emerging as a rapid audit solution, reducing hours of cycle counting to mere minutes.

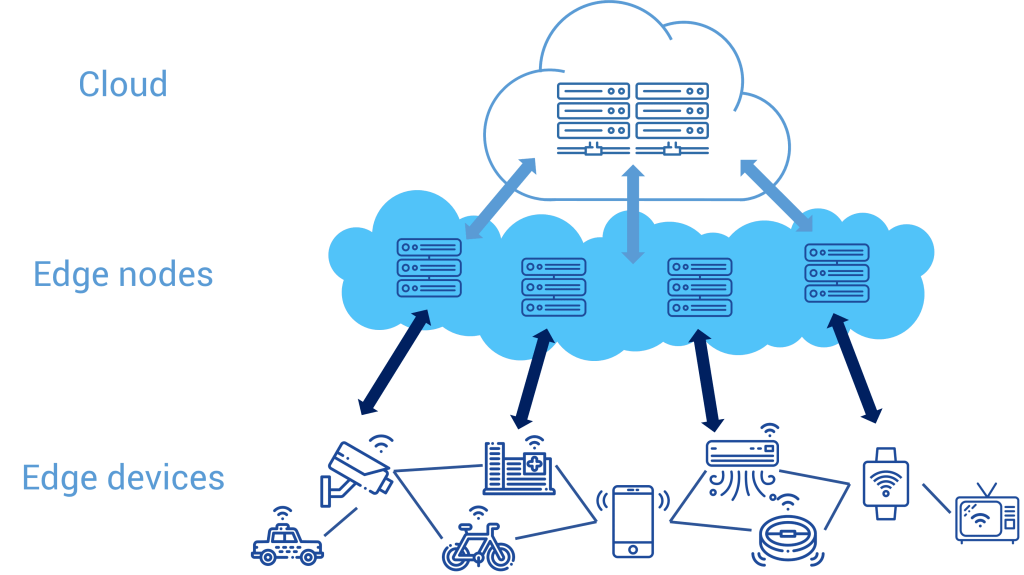

Edge computing enables faster decision-making by processing IoT data near the source rather than transmitting everything to centralized cloud servers. This reduces latency, which is crucial for real-time applications such as collision avoidance for AGVs or instant condition-based alerts.

Conclusion

IoT has shifted the paradigm of inventory accuracy from periodic manual verification to real-time automated intelligence. By enabling seamless tracking, automated stock updates, condition monitoring, and predictive insights, IoT empowers logistics companies to deliver higher accuracy, faster fulfillment, and reliable service. Integrating IoT into warehousing is essential for operational excellence and competitiveness in any supply chain-dependent business.

Platforms such as PostalParcel, which incorporate IoT data into their inventory and fulfillment solutions, demonstrate how technology-driven logistics can remain agile and efficient in a fast-evolving market.

Industry Insights

news via inbox

Nulla turp dis cursus. Integer liberos euismod pretium faucibua